Question

The Stik Pert Corporation assembles ball point pens at its Tennessee facility for its line of low priced office stationary products. The Tennessee facility produces

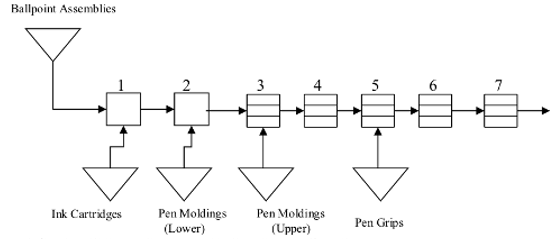

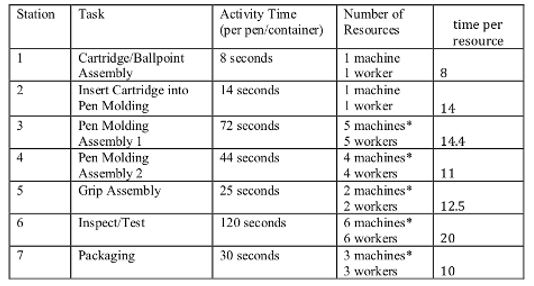

The Stik Pert Corporation assembles ball point pens at its Tennessee facility for its line of low priced office stationary products. The Tennessee facility produces pens fix distribution throughout North America on four assembly lines. Each pen assembly line consists of seven stations connected by a high speed conveyor system and automated material handing equipment that move individual pen assemblies along a fully connected machine paced line. The overall flow is illustrated in Figure 1. Sec Table 1 for a summary of the process steps.

Figure 1 Stik Pen Ballpoint Pen Assembly Line Process Flow Diagram

Multiple machines work in parallel, i.e. flow is synchronized so that material is routed from the input conveyor to an individual machine for processing and the processed and the processed materials

Assume that questions refer to one line which runs for 2 consecutive 8-hour shifts per day, unless otherwise stated. Ouestions are 2 Points each unless otherwise indicated.

1. What is the capacity of the line?

2. What is the Direct Labor Content of a pen? Note that the machine time is equal to the operator time.

3. How much time does it take to get one pen through the system?

4. What is the direct labor cost per pen? Assume that each worker is paid $20 / hour.

5. Assume that the average demand is 16,000 pens per day, pcsu mint? four lint" and (yin 8-hour shift. per day. What is the utilisation of Station 5, Grip Assembly on a line?

Ballpoint Assemblies Ink Cartridges Pen Moldings (Lower) Pen Moldings (Upper) Pen Grips Station 1 2 3 4 5 6 7 Task Cartridge/Ballpoint Assembly Insert Cartridge into Pen Molding Pen Molding Assembly 1 Pen Molding Assembly 2 Grip Assembly Inspect/Test Packaging Activity Time (per pen/container) 8 seconds 14 seconds 72 seconds 44 seconds 25 seconds 120 seconds 30 seconds Number of Resources 1 machine I worker I machine I worker 5 machines* 5 workers 4 machines 4 workers 2 machines* 2 workers 6 machines* 6 workers 3 machines* 3 workers 8 time per resource 14 14.4 11 12.5 20 10

Step by Step Solution

3.36 Rating (159 Votes )

There are 3 Steps involved in it

Step: 1

1 Capacity of the line is equal to the capacity of slowest resource w...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Document Format ( 2 attachments)

609a83b1b5a49_30700.pdf

180 KBs PDF File

609a83b1b5a49_30700.docx

120 KBs Word File

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started