Answered step by step

Verified Expert Solution

Question

1 Approved Answer

6 - 1 Fabufirst, (page 301) a. Use a probability tree and calculate the probabilities of each possible outcome. What is the probability of

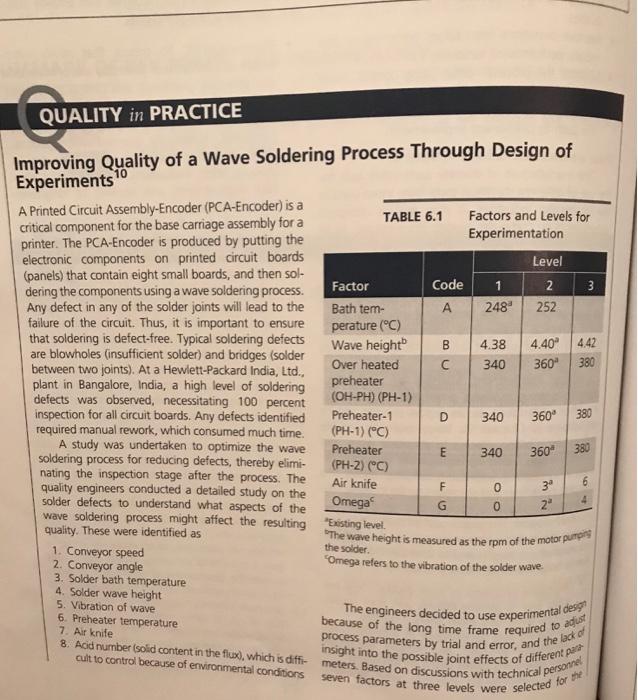

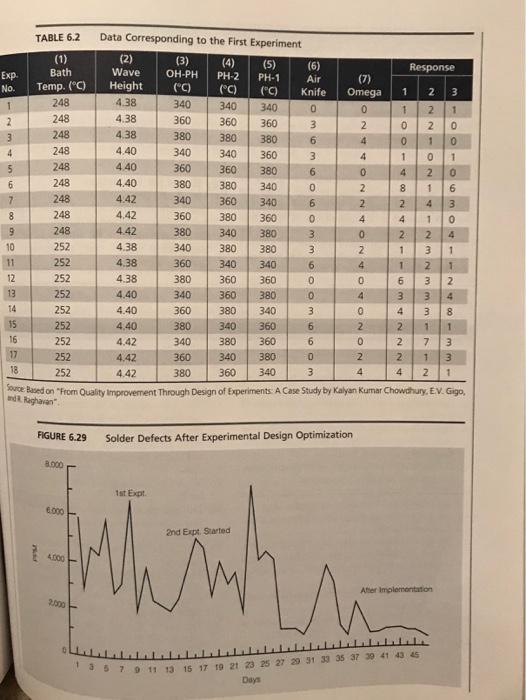

6 - 1 Fabufirst, (page 301) a. Use a probability tree and calculate the probabilities of each possible outcome. What is the probability of producing repairable assembled units? b. Summarize the results of the probability tree, and explain the results in terms of the multiplication and addition rules of probability. 6 - 3 Turkalike Rug Company (page 301) a. What is the probability of finding exactly 6 defects in a carpet roll chosen at random? b. What is the probability of finding 3 or fewer defects in a roll of carpet? process parameters by trial and error, and the lack of seven factors at three levels were selected for the/ The engineers decided to use experimental design The wave height is measured as the rpm of the motor pumprg meters. Based on discussions with technical personnel insight into the possible joint effects of different par QUALITY in PRACTICE Improving Quality of a Wave Soldering Process Through Design of Experiments A Printed Circuit Assembly-Encoder (PCA-Encoder) is a critical component for the base carriage assembly for a printer. The PCA-Encoder is produced by putting the electronic components on printed circuit boards (panels) that contain eight small boards, and then sol- dering the components using a wave soldering process. Any defect in any of the solder joints will lead to the failure of the circuit. Thus, it is important to ensure that soldering is defect-free. Typical soldering defects are blowholes (insufficient solder) and bridges (solder between two joints). At a Hewlett-Packard India, Ltd., plant in Bangalore, India, a high level of soldering defects was observed, necessitating 100 percent inspection for all circuit boards. Any defects identified required manual rework, which consumed much time. A study was undertaken to optimize the wave soldering process for reducing defects, thereby elimi- nating the inspection stage after the process. The quality engineers conducted a detailed study on the solder defects to understand what aspects of the wave soldering process might affect the resulting quality. These were identified as TABLE 6.1 Factors and Levels for Experimentation Level Factor Code 1 2 248 252 Bath tem- perature (C) Wave height A B 4.38 4.40 4.42 Over heated C 340 360 380 preheater (OH-PH) (PH-1) Preheater-1 340 360 380 (PH-1) (C) Preheater 340 360 380 (PH-2) (C) Air knife 3 Omega G 2" "Existing level. the solder. 1. Conveyor speed 2. Conveyor angle 3. Solder bath temperature 4. Solder wave height 5. Vibration of wave 6. Preheater temperature 7. Air knife Acid number (solid content in the flux), which is diffi- cult to control because of environmental conditions "Omega refers to the vibration of the solder wave because of the long time frame required to adist O O E. TABLE 6.2 Data Corresponding to the First Experiment (1) Bath (2) Wave (3) OH-PH (4) (5) (6) Response Exp. No. PH-2 PH-1 Air (7) Temp. ("C) Height ("C) ("C) ("C) Knife Omega 2 3 248 4.38 340 340 1 2 1 340 248 4.38 360 360 360 20 3 2. 248 4.38 380 380 380 6. 1. 4 248 4.40 340 340 360 3. 1 0. 248 4.40 360 360 380 4 248 4.40 380 380 340 2 8 248 4.42 340 360 340 9. 2 8 248 4.42 360 380 360 4 4 6. 248 4.42 380 340 380 3. 2. 10 252 4.38 340 380 380 3. 11 252 4.38 360 340 340 6. 4. 1. 12 252 4.38 380 360 360 13 252 4.40 340 360 380 4. 3. 14 252 4.40 360 380 340 3 4 3 8. 15 252 4.40 380 340 360 6. 2 2. 1. 16 252 4.42 340 380 360 7 3 17 252 4.42 360 340 380 18 252 4.42 380 360 340 3 4 4 oce Based on "From Quality Improvement Through Design of Experiments. A Case Study by Kalyan Kumar Chowdhury. EV. Gigo, wdR Raghavan. FIGURE 6.29 Solder Defects After Experimental Design Optimization 8.000 1st Expt. E.000 2nd Expt. Started 4000 Ater Implementation 2000 Days 001 063 0411 240 O21 412N 32m mm ON S67 oc

Step by Step Solution

★★★★★

3.48 Rating (155 Votes )

There are 3 Steps involved in it

Step: 1

PD1 015 and PD2 01 i PD1PD2 01501 00150 ii PD1PD2 ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started