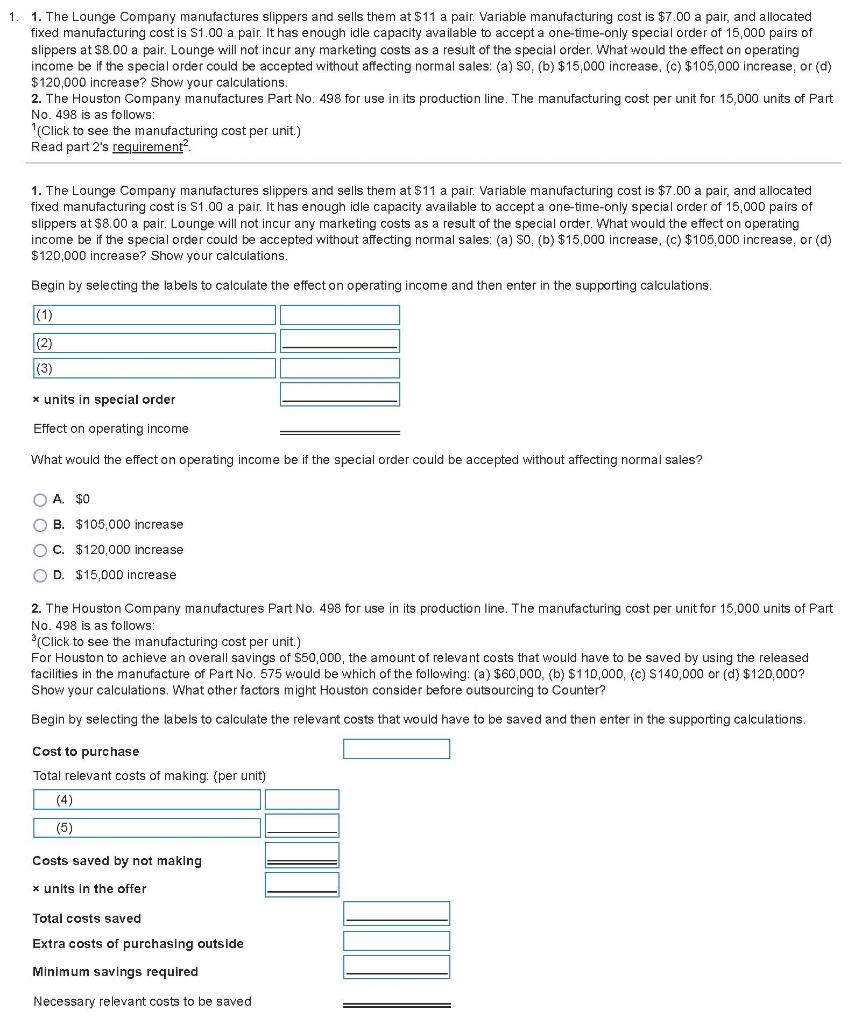

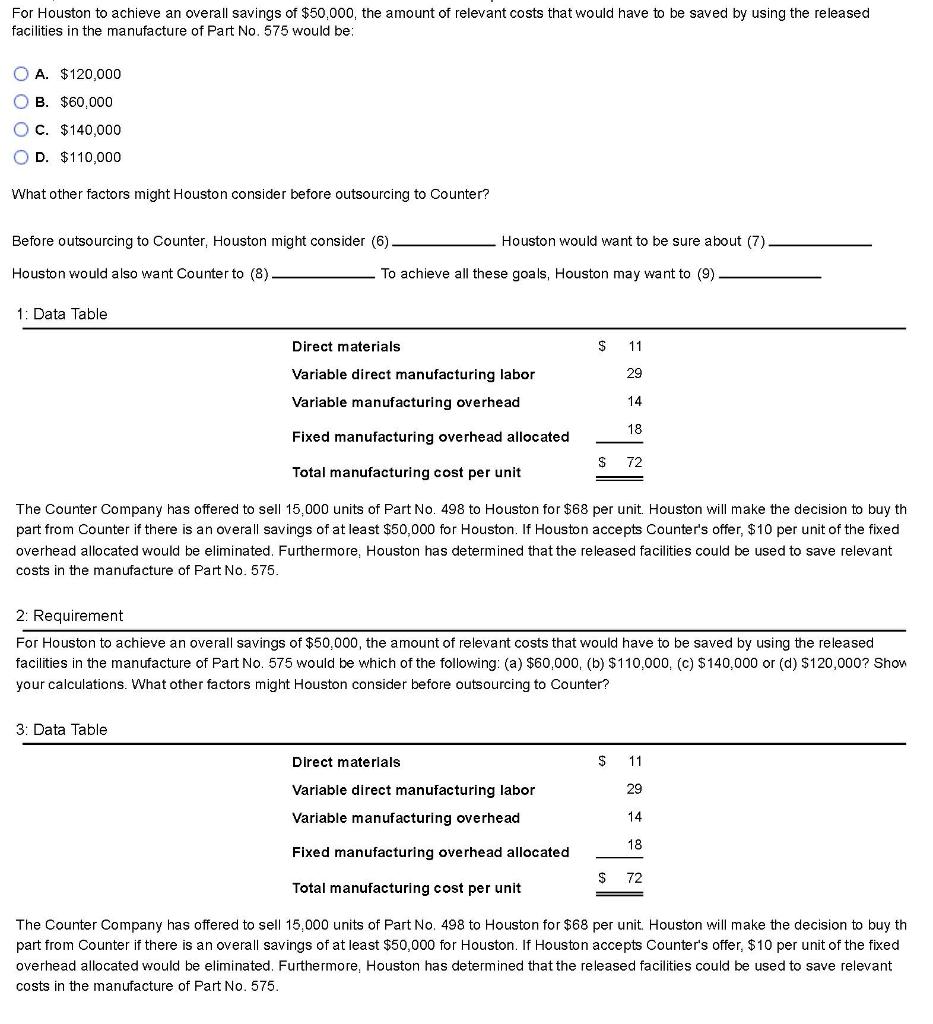

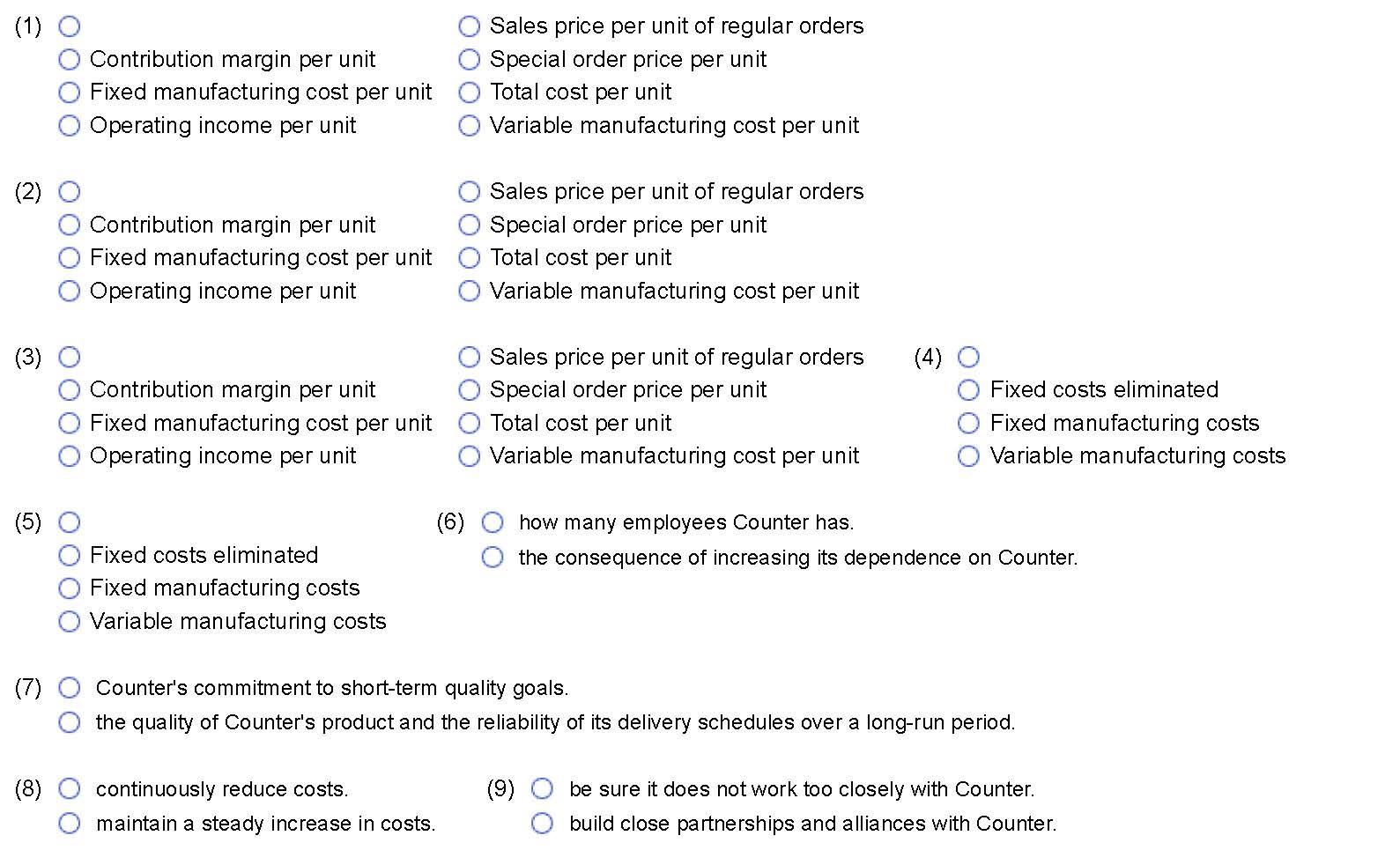

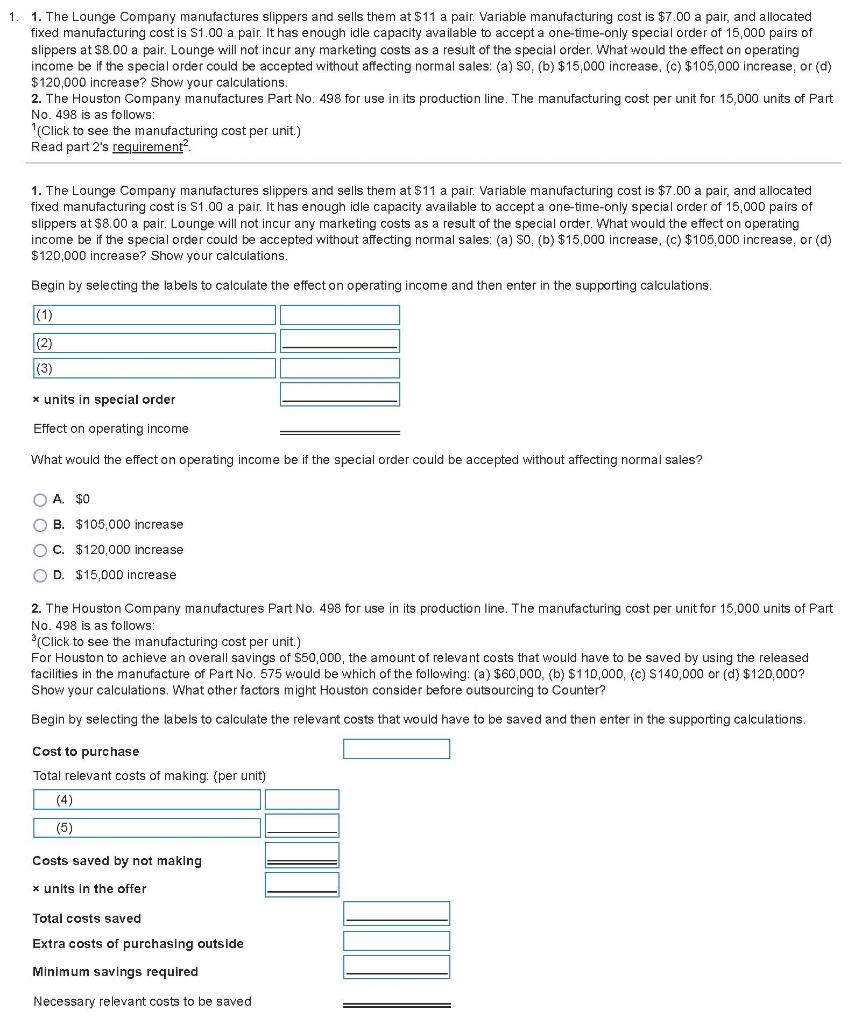

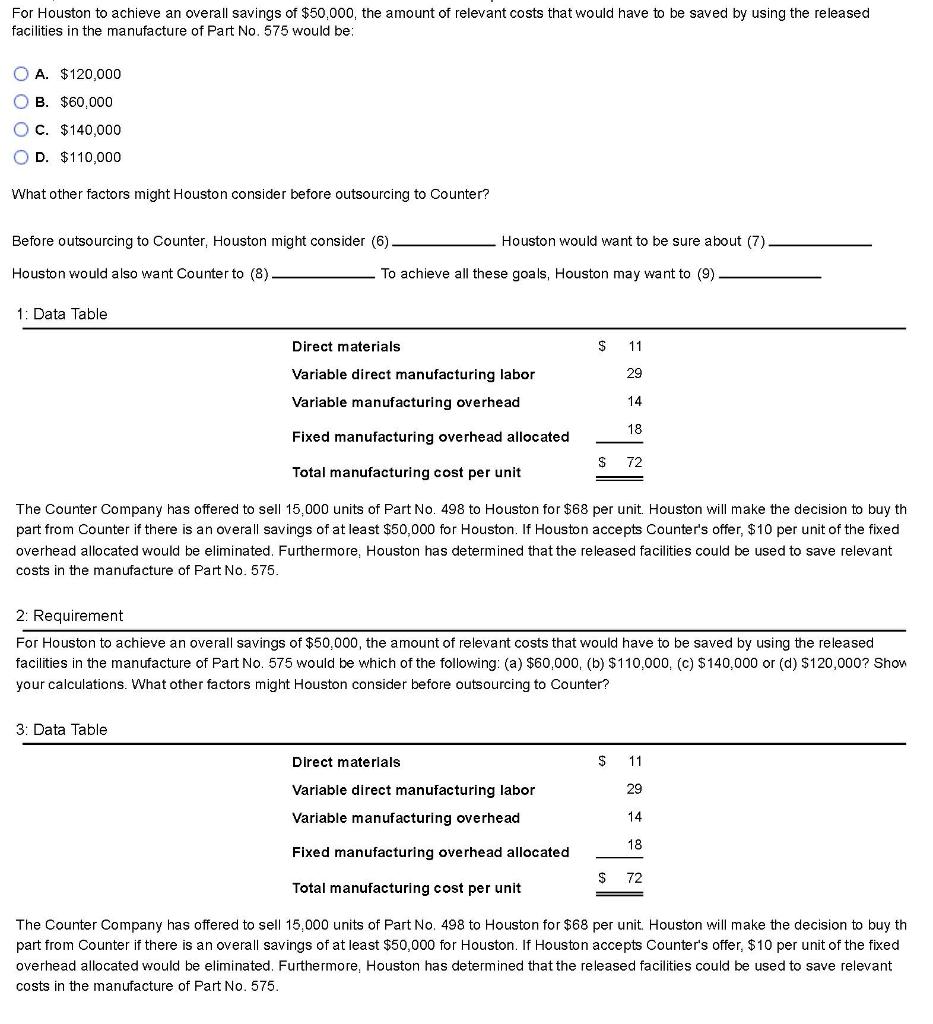

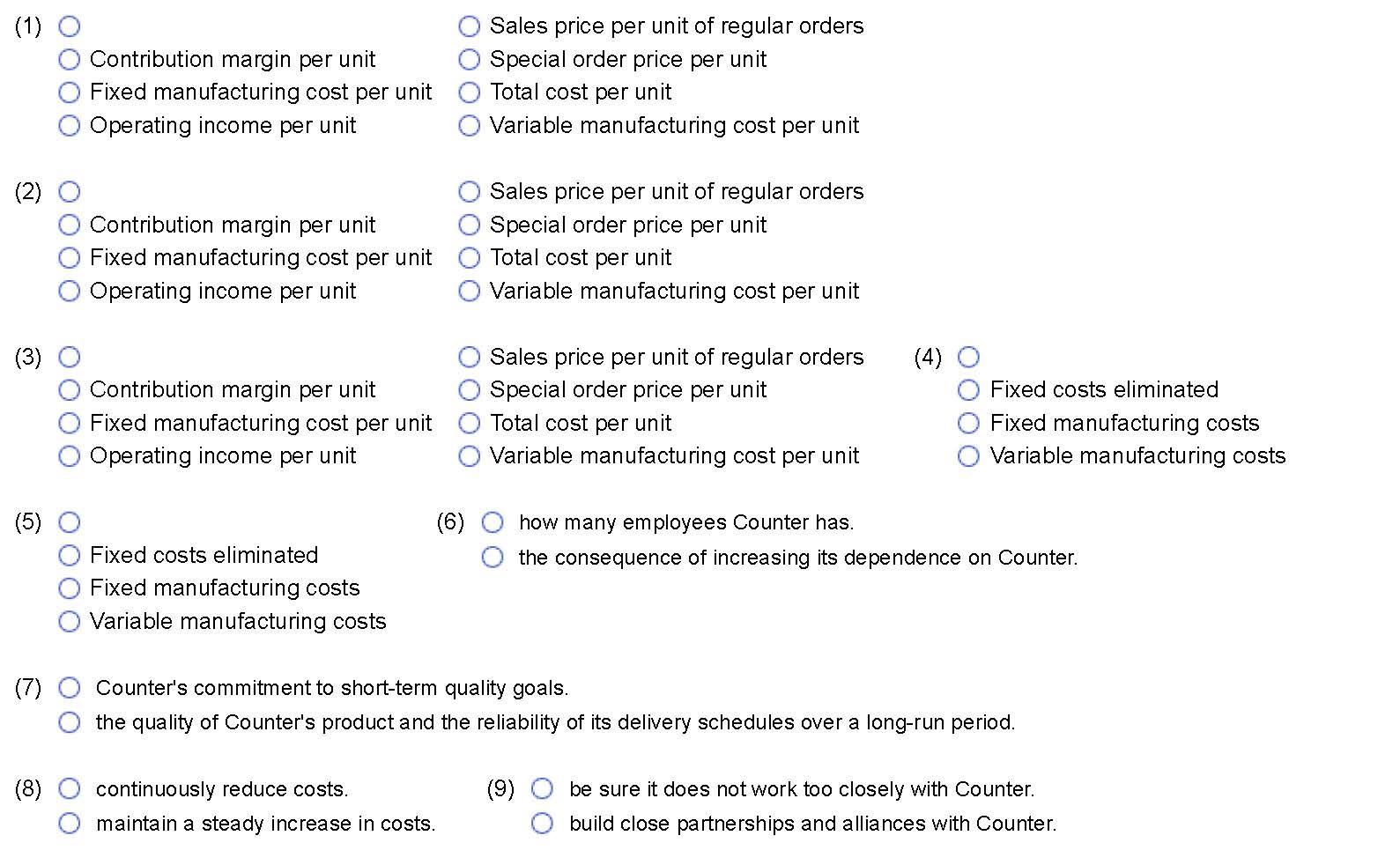

1. The Lounge Company manufactures slippers and sells them at $11 a pair. Variable manufacturing cost is $7.00 a pair, and allocated fixed manufacturing cost is $1.00 a pair. It has enough idle capacity available to accept a one-time-only special order of 15,000 pairs of slippers at $8.00 a pair. Lounge will not incur any marketing costs as a result of the special order. What would the effect on operating income be if the special order could be accepted without affecting normal sales: (a) $0, (b) $15,000 increase, (c) $105,000 increase, or (d) $120,000 increase? Show your calculations. 2. The Houston Company manufactures Part No. 498 for use in its production line. The manufacturing cost per unit for 15,000 units of Part No. 498 is as follows: 1 (Click to see the manufacturing cost per unit.) Read part 2 's requirement 2. 1. The Lounge Company manufactures slippers and sells them at $11 a pair. Variable manufacturing cost is $7.00 a pair, and allocated fixed manufacturing cost is $1.00 a pair. It has enough idle capacity available to accept a one-time-only special order of 15,000 pairs of slippers at $8.00 a pair. Lounge will not incur any marketing costs as a result of the special order. What would the effect on operating income be if the special order could be accepted without affecting normal sales: (a) SO, (b) $15,000 increase, (c) $105,000 increase, or (d) $120,000 increase? Show your calculations. Begin by selecting the labels to calculate the effect on operating income and then enter in the supporting calculations. What would the effect on operating income be if the special order could be accepted without affecting normal sales? A. $0 B. $105,000 increase C. $120,000 increase D. $15,000 increase 2. The Houston Compeny manufactures Part No. 498 for use in its production line. The manufacturing cost per unit for 15,000 units of Part No. 498 is as follows: 3 (Click to see the manufacturing cost per unit.) For Houston to achieve an overall savings of $50,000, the amount of relevant costs that would have to be saved by using the released facilities in the manufacture of Part No. 575 would be which of the following: (a) $60,000, (b) $110,000, (c) $140,000 or (d) $120,000 ? Show your calculations. What other factors might Houston consider before outsourcing to Counter? Begin by selecting the labels to calculate the relevant costs that would have to be saved and then enter in the supporting calculations. For Houston to achieve an overall savings of $50,000, the amount of relevant costs that would have to be saved by using the released facilities in the manufacture of Part No. 575 would be: A. $120,000 B. $60,000 C. $140,000 D. $110,000 What other factors might Houston consider before outsourcing to Counter? Before outsourcing to Counter, Houston might consider (6) Houston would want to be sure about (7) Houston would also want Counter to (8) To achieve all these goals, Houston may want to (9) The Counter Company has offered to sell 15,000 units of Part No. 498 to Houston for $68 per unit. Houston will make the decision to buy th part from Counter if there is an overall savings of at least $50,000 for Houston. If Houston accepts Counter's offer, $10 per unit of the fixed overhead allocated would be eliminated. Furthermore. Houston has determined that the released facilities could be used to save relevant costs in the manufacture of Part No. 575. 2: Requirement For Houston to achieve an overall savings of $50,000, the amount of relevant costs that would have to be saved by using the reased facilities in the manufacture of Part No. 575 would be which of the following: (a) $60,000, (b) $110,000 : (c) $140,000 or (d) $120,000 ? Shon your calculations. What other factors might Houston consider before outsourcing to Counter? The Counter Company has offered to sell 15,000 units of Part No. 498 to Houston for $68 per unit. Houston will make the decision to buy th part from Counter if there is an overall savings of at least $50,000 for Houston. If Houston accepts Counter's offer, $10 per unit of the fixed overhead allocated would be eliminated. Furthermore. Houston has determined that the released facilities could be used to save relevant costs in the manufacture of Part No. 575. Contribution margin per unit Special order price per unit Fixed manufacturing cost per unit Total cost per unit Operating income per unit Variable manufacturing cost per unit Sales price per unit of regular orders Contribution margin per unit Special order price per unit Fixed manufacturing cost per unit Total cost per unit Operating income per unit Variable manufacturing cost per unit Sales price per unit of regular orders (4) Contribution margin per unit Special order price per unit Fixed cos Fixed manufacturing cost per unit Total cost per unit Fixed ma Operating income per unit Variable manufacturing cost per unit Variable (6) how many employees Counter has. Fixed costs eliminated the consequence of increasing its dependence on Counter. Fixed manufacturing costs Variable manufacturing costs Counter's commitment to short-term quality goals. the quality of Counter's product and the reliability of its delivery schedules over a long-run period