Question: 1. What are the most interesting points presented in the case and why? 2. What are some of the challenges presented and how can they

1. What are the most interesting points presented in the case and why?

2. What are some of the challenges presented and how can they be mitigated?

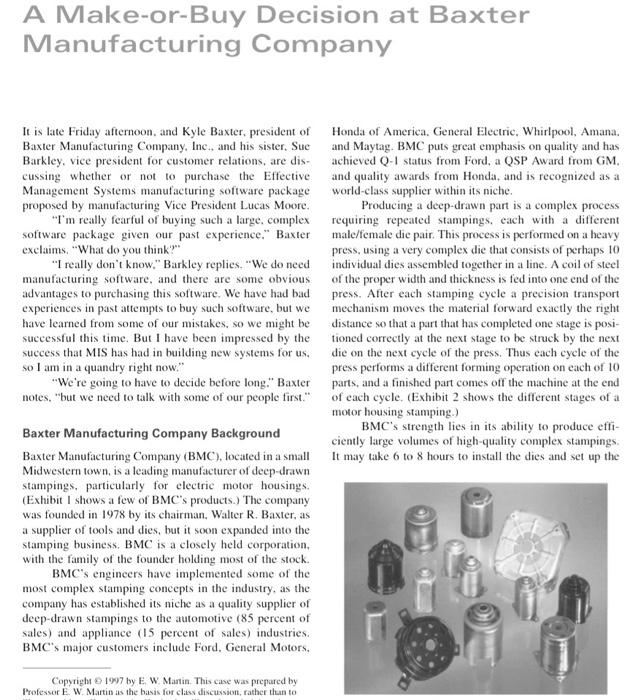

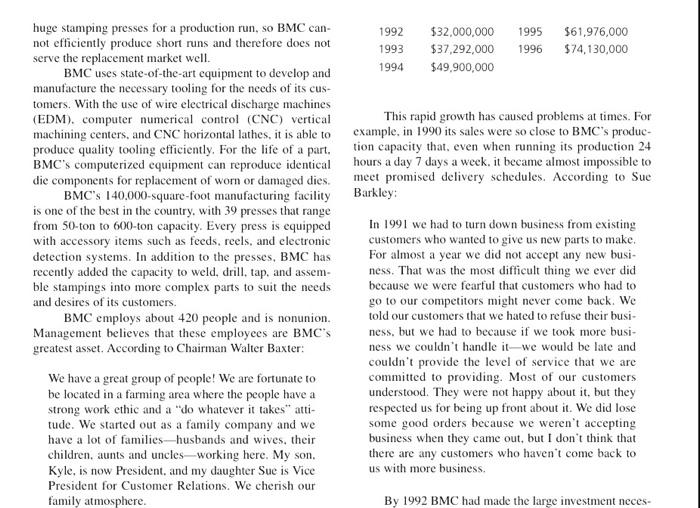

A Make-or-Buy Decision at Baxter Manufacturing Company It is late Friday afternoon, and Kyle Baxter, president of Honda of America. General Electric, Whirlpool, Amana. Baxter Manufacturing Company, Inc., and his sister, Sue and Maytag. BMC puts great emphasis on quality and has Barkley, vice president for customer relations, are dis- achieved 0-1 status from Ford, a QSP Award from GM. cussing whether or not to purchase the Effective and quality awards from Honda, and is recognized as a Management Systems manufacturing software package world-class supplier within its niche. proposed by manufacturing Vice President Lucas Moore, Producing a deep-drawn part is a complex process "I'm really fearful of buying such a large, complex requiring repeated stampings, each with a different software package given our past experience." Baxter male/female die pair. This process is performed on a heavy exclaims. "What do you think?" press, using a very complex die that consists of perhaps 10 "I really don't know." Barkley replies. "We do need individual dies assembled together in a line. A coil of steel manufacturing software, and there are some obvious of the proper width and thickness is fed into one end of the advantages to purchasing this software. We have had bad press. After each stamping cycle a precision transport experiences in past attempts to buy such software, but we mechanism moves the material forward exactly the right have learned from some of our mistakes, so we might be distance so that a part that has completed one stage is posi- successful this time. But I have been impressed by the tioned correctly at the next stage to be struck by the next success that MIS has had in building new systems for us. die on the next cycle of the press. Thus each cycle of the so I am in a quandry right now." press performs a different forming operation on each of 10 "We're going to have to decide before long." Baxter parts, and a finished part comes off the machine at the end notes, "but we need to talk with some of our people first." of each cycle. (Exhibit 2 shows the different stages of a motor housing stamping.) Baxter Manufacturing Company Background BMC's strength lies in its ability to produce effi- ciently large volumes of high-quality complex stampings Baxter Manufacturing Company (BMC), located in a small It may take 6 to 8 hours to install the dies and set up the Midwestern town, is a leading manufacturer of deep-drawn stampings, particularly for electric motor housings. (Exhibit I shows a few of BMC's products. The company was founded in 1978 by its chairman, Walter R. Baxter, as al supplier of tools and dies, but it soon expanded into the stamping business. BMC is a closely held corporation, with the family of the founder holding most of the stock. BMC's engineers have implemented some of the most complex stamping concepts in the industry, as the company has established its niche as a quality supplier of deep-drawn stampings to the automotive (85 percent of sales) and appliance (15 percent of sales) industries. BMC's major customers include Ford, General Motors. Copyright 1997 by E. W Martin. This case was prepared by Professor E. W. Martin as the basis for class discussion, rather than to huge stamping presses for a production run, so BMC can- 1992 $32,000,000 1995 $61,976,000 not efficiently produce short runs and therefore does not 1993 $37,292,000 1996 $74,130,000 serve the replacement market well. 1994 BMC uses state-of-the-art equipment to develop and $49,900,000 manufacture the necessary tooling for the needs of its cus- tomers. With the use of wire electrical discharge machines (EDM). computer numerical control (CNC) vertical This rapid growth has caused problems at times. For machining centers, and CNC horizontal lathes, it is able to example, in 1990 its sales were so close to BMC's produc- produce quality tooling efficiently. For the life of a part. tion capacity that, even when running its production 24 BMC's computerized equipment can reproduce identical hours a day 7 days a week. it became almost impossible to die components for replacement of worn or damaged dies. meet promised delivery schedules. According to Sue BMC's 140,000-square-foot manufacturing facility Barkley: is one of the best in the country, with 39 presses that range from 50-ton to 600-ton capacity. Every press is equipped In 1991 we had to turn down business from existing with accessory items such as feeds, reels, and electronic customers who wanted to give us new parts to make. detection systems. In addition to the presses, BMC has For almost a year we did not accept any new busi- recently added the capacity to weld, drill, tap, and assem- ness. That was the most difficult thing we ever did ble stampings into more complex parts to suit the needs because we were fearful that customers who had to and desires of its customers. go to our competitors might never come back. We BMC employs about 420 people and is nonunion. told our customers that we hated to refuse their busi- Management believes that these employees are BMC's ness, but we had to because if we took more busi- greatest asset. According to Chairman Walter Baxter: ness we couldn't handle itwe would be late and couldn't provide the level of service that we are We have a great group of people! We are fortunate to committed to providing. Most of our customers be located in a farming area where the people have a understood. They were not happy about it, but they strong work ethic and a "do whatever it takes" atti- respected us for being up front about it. We did lose tude. We started out as a family company and we some good orders because we weren't accepting have a lot of families--husbands and wives, their business when they came out, but I don't think that children, aunts and uncles-working here. My son, there are any customers who haven't come back to Kyle, is now President, and my daughter Sue is Vice us with more business. President for Customer Relations. We cherish our family atmosphere. By 1992 BMC had made the large investment neces- minimal inventories of raw materials and parts. Rather than This spreadsheet, which is still used today, contains data for sending an order for a month's parts at a time as they had in each part, including the machine used the number produced the past, the customers began telling BMC one day what to per hour, and the setup time. The quantity required and the ship on the next. BMC was provided with a blanket order for delivery date are entered, and the spreadsheet determines planning, but the customers reserved the right to change the when each part should be started into production and amounts at the last minute generates a schedule of what should be run when on each Including the time to procure the raw materials, run machine group. If the schedule is not feasible (eg.. some them through the presses to make the parts. clean and pack parts must be started last week). the scheduler can make them, and ship them out, BMC's production process manual adjustments in due date, quantity required, overtime. requires at least two weeks if things go well. Thus the and other factors to produce a feasible schedule. automotive companies are forcing their suppliers to main- Realizing that they needed someone to lead and lain their inventories for them, which places great pressure educate them in the use of computers, in 1989 BMC on BMC to reduce its cycle times. Because of its two-week management set up an MIS department and hired an MIS production cycle and long setup times. BMC is often manager, Nancy Shaw. BMC installed a Data General MV forced to maintain a finished goods inventory that is minicomputer, and the first application was interoffice substantially above its target of a three-day supply e-mail. This was a great way to start because it demon About five years ago its automotive customers began to strated how helpful the computer could be in sharing pressure BMC to convert to electronic data interchange information. According to Sue Barkley (EDI), where all paper document flows between customer and supplier are replaced by electronic flows directly between E-mail was very well received because we were the customer's computer and BMC's computer. Thus BMC growing so rapidly and the need to communicate receives all purchase orders and shipping schedules electron within the plant was so important. It wasn't until we ically and sends out electronic shipping notices and bills. EDI got on e-mail that we realized how much time we has the potential to be quicker and more efficient for both par- had been spending running around the plant trying ties, but BMC's factory computer systems were incomplete to find somebody and leaving little notes on their and fragmented, so for several years BMC accepted the data desk. We really became dependent on our e-mail electronically, printed it out, and then rekeyed the data into system , those relevant systems that existed. The IS department is now building interfaces to enter the EDI data directly into some of During the next two years Shaw led the purchase and BMC's systems. One reason for this delay was that their auto- successful installation of a package of financial applica- mobile customers use one EDI standard while their appliance tions, including payroll, accounts payable and receivable. customers use another, and each customer has its own varia- and general ledger. Also, in 1989 BMC was beginning to tion on the standard it uses. BMC has had to build a separate encounter problems in production because of its growing subsystem to handle each of its customers. capacity problems and its customers' switch to JIT. When customers changed their requirements, the production Information Systems at BMC schedule had to be changed, which forced changes in the schedules of other parts, and production people seemed to BMC's managers have been very receptive to the introduc- be spending all their time rescheduling things. Because tion of new technology. They were carly adopters of demand was so near to capacity, it was difficult to get all the CAD/CAM, and are at the forefront of stamping technology, orders done on time, and there was a lot of expediting going However, they have had little experience with the use of on, which again led to the need to reschedule. Although computers in business applications and have limited under there was no computer support for manufacturing other standing of what the technology can do for them. than the spreadsheet used for scheduling, BMC's manage- BMC got its first PCs in 1987, and a few managers ment decided that if scheduling could be speeded up, the started experimenting with Lotus spreadsheets. One of the problems would be alleviated. Consequently, the decision first applications they set up was a spreadsheet for generating was made to purchase a software package for scheduling customer quotes by calculating what price to charge for a Sue Barkley, who was involved in the process. part based on estimates of raw material cost, tooling costs. remembers: the costs of stamping, and the expected quantity to be produced. Another early use of the PC was a scheduling Our MIS manager, Nancy Shaw, did some research spreadsheet developed by the company president, Kyle and selected four packages from which we tried to Baxter, when serving as vice president for manufacturing choose the best one. That was my first exposure Case Study II-2A Make-e-Buy Decision at Barter Manufacturing Company 445 to software, and it was a terrible experience. Each change another five machines, and I have to go vendor claimed that his software would do anything through the cycle again. It's just a continuous you wanted to do, and there were so many questions process of change, change, change!" we should have asked but didn't We tried for another month to make the system Vendors all offered integrated packages that work for us, but we were in such bad shape with our included production scheduling, but you also gor capacity that we just couldn't take the time to try to sales, inventory. purchasing, shipping, etc. We made cope with the system anymore. So we abandoned it our selection and paid about $120,000 for the sys- and went back to our Lotus spreadsheet. The tem, including both hardware and software, which S150.000 that we had spent for that system was was a large expenditure for us at the time. down the drain! Then we started to load the data and imple- ment the scheduling package. The training the ven- dor provided was poor, the manual was full of crrors. The Present MIS Department and support from the vendor was minimal. We In 1994 Shaw left and BMC hired Don Collins to replace worked and worked and finally became so frustrated het as MIS manager. Collins had 20 years of experience as by our inability to get the system to do what we alcad systems analyst with a large manufacturer and broad wanted it to that we just gave up. On top of every experience with manufacturing systems. In 1996. Collins thing else the vendor went bankrupt. It was a total has a programming staff of four. The 1996 capital budget disaster-S120.000 down the tube! for hardware, software, and other information technology items was about $200,000. The MIS expense budget for As mentioned previously, by 1991 the problems in payroll, supplies, and education was about $350,0%) meeting shipping schedules had gotten so bad that BMC The MIS department is using a development tool began to have to turn down new business Management called Cyber Query Cyber Screen (CQCS) from Cyber again decided that they had to do something about machine Science, but Collins is giving some thought to what BMC'S scheduling, so again they decided to purchase a scheduling development environment of the future should be. The package. Sue Barkley remembers Data General MV computer is becoming obsolete and is reaching capacity, so BMC will have to obtain additional This time things went better. Nancy Shaw and I got capacity soon more people involved in the decision on what pack- In order to plan a production schedule you need to age to buy. This vendor provided some in-depth know what you have in inventory, so the MIS group has training to our MIS people, and vendor people came created systems to track raw material. in process, and fin down here for 2 weeks to help us load the data and ished-goods inventories. MIS has also developed a mini- get the production scheduling module working, computer system that accepts EDI orders from customers Again, we found that the manual was full of crrors and allows the customer service group to create a shipping and that the vendor people did not fully understand schedule on the computer. Collins believes that within 2 the logic that the system was using. But we got the more years the MIS group can build and install a set of system up and working and taught the production manufacturing systems that will satisfy BMC's basic needs scheduling people how to use it. and provide quite satisfactory EDI service to customers. The problem was that whenever we had to This success in building new systems opened BMC expedite something-give it top priority because it managers' eyes to the possibilities for using the computer, had to be shipped quickly--the schedule had to be and they have generated so many requests for new systems regenerated, and that took 2 hours. Then we had to that an MIS steering committee has been established to take the schedule for cach machine and examine it to approve projects and set systems development priorities. see what the impact on its schedule was and change The members of the MIS steering committee are President what it was going to do. Because we were always Kyle Baxter. Controller Lou Wilcox, Sue Barkley, and Don expediting something, we were constantly churning, Collins. After about a month the production scheduler came to me and said. "I'm not getting anything done. It takes me 2 hours to regenerate a schedule I look at The New Proposal it and I then have to change five or six machines In late 1996 Lucas Moore, vice president of manufactur- because of what the system did. Then it takes me 2 ing. suggested that BMC purchase and install an integrated more hours to generate a new schedule and I have to package of manufacturing software sold by Effective 446 Part III. Acquiring Information Systems Management Systems, Inc. (EMS). Moore has worked as an engineer with the company for 7 years and then took a leave for 2 years to get an MBA. The vice president of manufacturing retired soon after Moore returned, and Mocxre was promoted to that management position Moore supports the proposal that BMC install the EMS Time Critical Manufacturing package consisting of eight modules: shop floor control. EDI integration, inven- tory management, factory data collection, standard rout ings, labor collection engineered product configurator and general ledger. The purchase price of this software package is $220,000, including documentation, training by EMS, and consulting help during installation of the software. The cost of a software maintenance contract is $55,000 a year, and EMS will make limited changes requested by BMC at a cost of $60 per hour. The EMS software will run on several minicomput ers, including BMC's Data General MV. However, addi tional computer capacity will be needed whether BMC purchases the EMS package or builds its own manufac- turing systems Moore's Views Moore is relatively new to the manufacturing area, having taken over that area about a year ago, and was not involved in the past attempts to purchase scheduling software Moore explained to Baxter that BMC should purchase the EMS package for the following reasons. We are still fudging our EDI and still scheduling with a Lotus spreadsheet. The entire industry has passed us by in our use of the computer in manufac. turing and we are in danger of losing our reputation as a world-class parts manufacturer. Both my MBA studies and our experience with the new inventory systems that Don has installed have convinced me that computer systems can significantly enhance our efficiency and improve our service to our customers, but we can't wait another 2 years to complete home-grown manufacturing systems that will still need to be upgraded before they are really first class I have had extensive discussions with EMS manufacturing specialists, read their literature, and seen the proposed systems demonstrated, and am convinced that the proposed system will do every- thing that we will ever want to do. EMS has assured me that there will be no problem integrating these manufacturing modules with our existing financial systems, and that we can be up and running with the entire system in 6 months Given that our MIS group is doing a good job de veloping new systems." Baxter asked, "why should we purchase the EMS package rather than build manufactur- ing systems in-house!" Moore's reply was: The time and cost differences between purchasing and building are too significant to ignore: 6 months to install this advanced system versus 2 years to build our own basic system, and a firm $220.000 10 purchase this system versus over $400,000 10 build our own. These costs do not include new hardware. but we will need to increase our capacity whether we purchase or build our new systems, Furthermore, we will get a high-quality state-of-the-art system instead of a simple "fast try system EMS has sold this system to hundreds of manufacturers, and thus has been able to spend much more time and money developing it than we could possibly afford. EMS has a large staff of more creative and sophisticated programmers than we can get, and EMS has gone through several cycles of improvement of this system based upon the experience of hundreds of users of the carlier versions of the system. It is true that the EMS system will not always do things the way we currently do them. But is the way we do them better than the way that is based on the experience of hundreds of manufacturers? We are always making changes in bow we do things, so it will not be difficult for us to make some changes to conform to this new software, and I expect that these changes will improve our operations. We have not been successful in two tries to use pur- chased software packages in the manufacturing area. Baxter noted. "What makes you think that we would be successful this timer" Moore replied: There are a number of important differences this time. First, in the past there was little ownership of the new system by the factory people, but this time I am the champion of the new system and my people will make it work. Second, in the past the conversion Strategy was flawed BMC tried to install schedul ing without having inventory data under control, but this time we will go at it a module at a time in the sequence that EMS has been very successful with in many previous installations. Third, during the previ ous attempts we were pushing capacity and no scheduling system was going to work when we were having to expedite everything, but today capacity is not a major problem and things are reasonably calm Case Study 111-2. A Make-or-Buy Decision at Baxter Manufacturing Company 447 in our factory so we can devete our energy to making He may or may not make the changes that you want. the new system successful and in fact he may make some changes that you do not want. If you do not expect the system to change and it Collins' Views is a common system, you probably should purchase it. For example, one general ledger system is just like Baxter also talked with Collins, who argued that BMC any other and they haven't changed in 20 years, so should continue its process of building the manufacturing you should purchase this application. But we are systems that it needed. He estimated that the needed sys. continually changing things out in the shop, and if we tems could be completed in about two years at a cost of build our own systems, we can change them when around $420,000 $220,000 for outside help (including we need to training his people in new development tools) and Finally, we have demonstrated that we can $200.000 in internal costs build and successfully install our own systems, but When Baxter asked Collins why BMC should not our record with purchasing and installing manufac- purchase the EMS software. Collins replied: turing systems is dismal. The EMS proposal may fulfill our needs, but then again it may not. We failed First, the EMS software is far more complicated than twice in the past because the system we purchased we need. For most general manufacturers each part did not fit our needs. Why take that chance again? may require six operations on six different types of machines, and each part has a routing that is differ **You seem very concerned that the EMS system ent than other parts. Then several parts may be might not suit our needs of that our needs might change." assembled into a subassembly, so you have two-or Baxter replied. "Could we modify this system if it does not three-level bills of material. We typically take a coil suit our needs Collins said of steel, stamp out the part, clean it box it, and ship it out, so both our routings and our bills of material Because we will not have a source code version of are very simple, as is our production process. The the software, it will not be feasible for our program- EMS system is designed for much more complex mers to modify the functionality of this system. manufacturing However, we can write interface software to change Second, we have had little or no experience the form of the system's input and output with computerized production systems. Does it make sense for us to try to jump to a very complex When Baxter noted the cost and time differences and sophisticated system like the EMS proposal between purchasing and building the system as estimated Lucas has a very superficial understanding of this by Moore. Collins replied: software package, and he doesn't know any of the details of how it will work. Therefore, he has no idea The figures Lucas quotes are very misleading. The of the difficulties that his people will run into in purchase price is but a part of the total cost of buy adapting to this complex package. It will require ing, installing, and maintaining the software. To be them to do many tasks that they have never done, or sure you are choosing software that truly meets your even considered doing. And they don't need this needs, you must put a substantial effort into defining complexity. Wouldn't it be better to build our own your needs and evaluating cach candidate package systems that correspond to where we are on the against those needs. One of the major weaknesses of learning curve and plan to upgrade them as we the present proposal is that this process of defining progress in our understanding of our systems needs? needs and evaluating possible packages has been Third, it is likely that the system does not fit completely ignored. In my opinion we must go the way we are running the business. Do we change through this process before buying any packaged the system or do we change how we run our busi software, and this will affect both the proposed cost ness? We probably can't change a purchased system. and how long it will take to install the system, so we would have to change the way we run the busi- Another cost of purchasing a system is the ness. Do we really want to do this? cost of modifying your existing systems so that they Fourth, we are constantly changing our manu can feed data to or receive data from the purchased facturing facilities and processes, and they may be package. If the systems that must be interfaced with unique to our business. If you purchase a package, you the purchased systems are also purchased systems are at the mercy of the vendor to make changes in it that you cannot modify you may have to create ourselves and decide which to do. That would take at least a year and cost between $50,000 and $90,000 Decision Time After his discussions with Moore and Collins, Baxter sat down with his sister, Sue Barkley, to discuss what to do about Moore's proposal. "Sue." Baxter began. "you were able to get the second manufacturing software system we bought up and running, but conditions in the shop were so chaotic that we abandoned trying to use it. Why don't we go back and try it again?" Sue replied: We recently considered trying again to use this system. but the special computer we bought to run it died and the software vendor has gone out of business, so we were out of luck. 448 Part III . Acquiring Information Systems additional systems to translate from one packaged system to the other packaged system. In addition there will be costs of training the users, data conver- sion, and the changeover to the new system. A good rule of thumb for the total cost of installing a pur- chased package would be twice the purchase price of the software, which in this case would be $440,000. I doubt that we could do it for any less. and that compares with about $420,000 to build our own systems, which includes all the costs involved, such as training.conversion, and defining the needs of our manufacturing people. It will take at least a year to properly evaluate and install a purchased system. This is less than the 2 years we will need to complete our own system. but we will be installing and using components of the new system as we complete them, so the time advantage is not that great. When asked what it would take to do a more complete evaluation of the proposal to purchase the EMS system, Collins replied: We would need to spend about 6 months studying our manufacturing area to determine what we are doing now and what the new systems should do. Then we would take some time to explore the many packages that are available, and winnow them down to the three or four most suitable. Then we would invite the chosen vendors to sub- mit proposals so we could study and evaluate each of these proposals in detail and pick the best one. Meantime, we would prepare a proposal for building the new system that would describe the proposed system in detail and include a plan for its development including schedules of both time and dollars. Finally, we would compare the best proposal with the plan for building the system "Lucas claims that BMC is losing its reputation as a world-class parts manufacturer because its systems are inadequate, and therefore BMC must purchase a system without delay." Baxter said. "Do you believe that it is critical that we get these new systems immediately Sue thought a while before replying: I don't think that our customers care about our sys- tems as long as we provide high-quality products at a good price and deliver them when they are needed, which we are doing. From their perspective, we are already interacting with them via EDI, so that is a problem for us rather than for them. It would be great to have the proposed systems as soon as possi- ble, but we have been getting along without them for a long time "Well. Sue." Baxter said, "I still don't know what we should do. What do you think