Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. What is the primary (largest) cause of the difference between actual cost per unit produced in the framing department and the standard cost per

1. What is the primary (largest) cause of the difference between actual cost per unit produced in the framing department and the standard cost per unit produced?

Favorable Price Variance

Unfavorable Price Variance

Favorable Efficiency Variance

Unfavorable Efficiency Variance

Favorable Volume Variance

Unfavorable Volume Variance

2. What is the total variance for the month?

3. Is the total variance for the month favorable or unfavorable?

Favorable

Unfavorable

Neither, total variance is 0

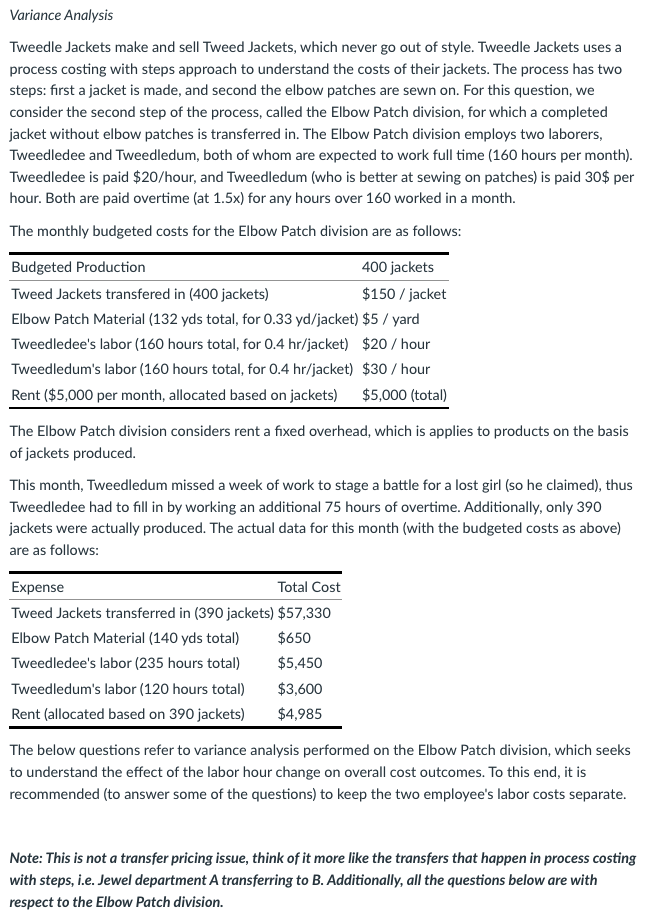

Variance Analysis Tweedle Jackets make and sell Tweed Jackets, which never go out of style. Tweedle Jackets uses a process costing with steps approach to understand the costs of their jackets. The process has two steps: first a jacket is made, and second the elbow patches are sewn on. For this question, we consider the second step of the process, called the Elbow Patch division, for which a completed jacket without elbow patches is transferred in. The Elbow Patch division employs two laborers, Tweedledee and Tweedledum, both of whom are expected to work full time (160 hours per month). Tweedledee is paid $20/hour, and Tweedledum (who is better at sewing on patches) is paid 30$ per hour. Both are paid overtime (at 1.5x) for any hours over 160 worked in a month. The monthly budgeted costs for the Elbow Patch division are as follows: Budgeted Production 400 jackets Tweed Jackets transfered in (400 jackets) $150 / jacket Elbow Patch Material (132 yds total, for 0.33 yd/jacket) $5 / yard Tweedledee's labor (160 hours total, for 0.4 hr/jacket) $20 /hour Tweedledum's labor (160 hours total, for 0.4 hr/jacket) $30 /hour Rent ($5,000 per month, allocated based on jackets) $5,000 (total) The Elbow Patch division considers rent a fixed overhead, which is applies to products on the basis of jackets produced. This month, Tweedledum missed a week of work to stage a battle for a lost girl (so he claimed), thus Tweedledee had to fill in by working an additional 75 hours of overtime. Additionally, only 390 jackets were actually produced. The actual data for this month (with the budgeted costs as above) are as follows: Expense Total Cost Tweed Jackets transferred in (390 jackets) $57,330 Elbow Patch Material (140 yds total) $650 Tweedledee's labor (235 hours total) $5,450 Tweedledum's labor (120 hours total) $3,600 Rent (allocated based on 390 jackets) $4,985 The below questions refer to variance analysis performed on the Elbow Patch division, which seeks to understand the effect of the labor hour change on overall cost outcomes. To this end, it is recommended (to answer some of the questions) to keep the two employee's labor costs separate. Note: This is not a transfer pricing issue, think of it more like the transfers that happen in process costing with steps, i.e. Jewel department A transferring to B. Additionally, all the questions below are with respect to the Elbow Patch divisionStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started