Answered step by step

Verified Expert Solution

Question

1 Approved Answer

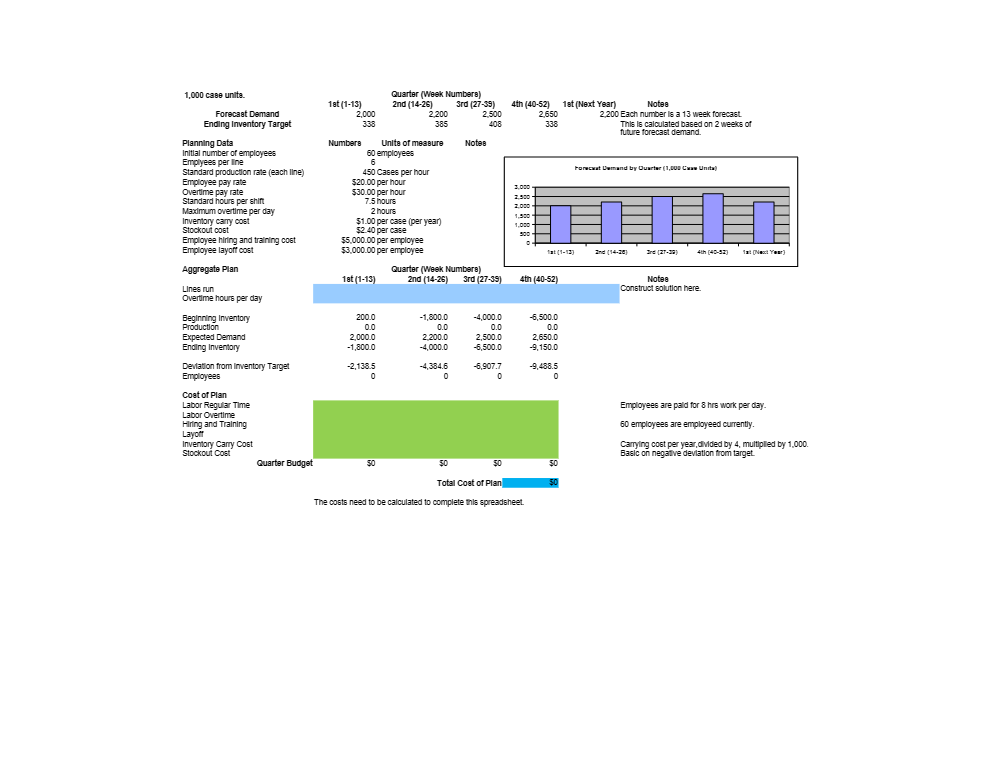

1,000case unita. Forecast Demand Ending Inventory Target Planning Data Inltial number of employees Emplyees per Ine Standard production rate (each llne) Employee pay rate Overtlme

1,000case unita. Forecast Demand Ending Inventory Target Planning Data Inltial number of employees Emplyees per Ine Standard production rate (each llne) Employee pay rate Overtlme pay rate Standard hours per enift Maximum overtime per day. Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Aggregate Plan Lines run Overtime hours per day Beginning Inventory Production Expected Demand Ending Inventory Devlation from inventory Targat Employees Coat of Plan Labor Regular Time Labor Overtime Hiring and Training Layod Inventory Carry Cost Stockout Cost 1 at (113) 2,000 336 1at (1-13) 2,000 338 Quarter (Week Number8) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) 2,200 Each number is a 13 week forecast. This ls calculated based on 2 weeks of future forecast demand. Numbers Units of measure Notes 60 employees 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 houre $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee Quarter (Week Numbere) 1 at (113) 2nd (14-26) 3rd (27-39) 4 th (4052) rarwat Dernand by Duarter (1,DUD Ciwaw Unita) 2,050 2,000 2,020 1,250 1,000 900 tat [712] Ind (142E] Irt(2720) 4th [4092] Noteg Construct solution here. 200.00.02,000.01,800.02,138.501,800.00.02,200.04,000.04,384.604,000.00.02,500.06,500.06,907.706,500.00.02,650.09,150.09,488.50 The costs need to be calculated to complete trls spreadsheet. Employees are pald for 8 hrs work per day. 60 employees are employeed currently. Carying cost per year, divided by 4, multipled by 1,000. Baslc on negative devlation from target. 1,000case unita. Forecast Demand Ending Inventory Target Planning Data Inltial number of employees Emplyees per Ine Standard production rate (each llne) Employee pay rate Overtlme pay rate Standard hours per enift Maximum overtime per day. Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Aggregate Plan Lines run Overtime hours per day Beginning Inventory Production Expected Demand Ending Inventory Devlation from inventory Targat Employees Coat of Plan Labor Regular Time Labor Overtime Hiring and Training Layod Inventory Carry Cost Stockout Cost 1 at (113) 2,000 336 1at (1-13) 2,000 338 Quarter (Week Number8) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) 2,200 Each number is a 13 week forecast. This ls calculated based on 2 weeks of future forecast demand. Numbers Units of measure Notes 60 employees 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 houre $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee Quarter (Week Numbere) 1 at (113) 2nd (14-26) 3rd (27-39) 4 th (4052) rarwat Dernand by Duarter (1,DUD Ciwaw Unita) 2,050 2,000 2,020 1,250 1,000 900 tat [712] Ind (142E] Irt(2720) 4th [4092] Noteg Construct solution here. 200.00.02,000.01,800.02,138.501,800.00.02,200.04,000.04,384.604,000.00.02,500.06,500.06,907.706,500.00.02,650.09,150.09,488.50 The costs need to be calculated to complete trls spreadsheet. Employees are pald for 8 hrs work per day. 60 employees are employeed currently. Carying cost per year, divided by 4, multipled by 1,000. Baslc on negative devlation from target

1,000case unita. Forecast Demand Ending Inventory Target Planning Data Inltial number of employees Emplyees per Ine Standard production rate (each llne) Employee pay rate Overtlme pay rate Standard hours per enift Maximum overtime per day. Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Aggregate Plan Lines run Overtime hours per day Beginning Inventory Production Expected Demand Ending Inventory Devlation from inventory Targat Employees Coat of Plan Labor Regular Time Labor Overtime Hiring and Training Layod Inventory Carry Cost Stockout Cost 1 at (113) 2,000 336 1at (1-13) 2,000 338 Quarter (Week Number8) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) 2,200 Each number is a 13 week forecast. This ls calculated based on 2 weeks of future forecast demand. Numbers Units of measure Notes 60 employees 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 houre $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee Quarter (Week Numbere) 1 at (113) 2nd (14-26) 3rd (27-39) 4 th (4052) rarwat Dernand by Duarter (1,DUD Ciwaw Unita) 2,050 2,000 2,020 1,250 1,000 900 tat [712] Ind (142E] Irt(2720) 4th [4092] Noteg Construct solution here. 200.00.02,000.01,800.02,138.501,800.00.02,200.04,000.04,384.604,000.00.02,500.06,500.06,907.706,500.00.02,650.09,150.09,488.50 The costs need to be calculated to complete trls spreadsheet. Employees are pald for 8 hrs work per day. 60 employees are employeed currently. Carying cost per year, divided by 4, multipled by 1,000. Baslc on negative devlation from target. 1,000case unita. Forecast Demand Ending Inventory Target Planning Data Inltial number of employees Emplyees per Ine Standard production rate (each llne) Employee pay rate Overtlme pay rate Standard hours per enift Maximum overtime per day. Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Aggregate Plan Lines run Overtime hours per day Beginning Inventory Production Expected Demand Ending Inventory Devlation from inventory Targat Employees Coat of Plan Labor Regular Time Labor Overtime Hiring and Training Layod Inventory Carry Cost Stockout Cost 1 at (113) 2,000 336 1at (1-13) 2,000 338 Quarter (Week Number8) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) 2,200 Each number is a 13 week forecast. This ls calculated based on 2 weeks of future forecast demand. Numbers Units of measure Notes 60 employees 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 houre $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee Quarter (Week Numbere) 1 at (113) 2nd (14-26) 3rd (27-39) 4 th (4052) rarwat Dernand by Duarter (1,DUD Ciwaw Unita) 2,050 2,000 2,020 1,250 1,000 900 tat [712] Ind (142E] Irt(2720) 4th [4092] Noteg Construct solution here. 200.00.02,000.01,800.02,138.501,800.00.02,200.04,000.04,384.604,000.00.02,500.06,500.06,907.706,500.00.02,650.09,150.09,488.50 The costs need to be calculated to complete trls spreadsheet. Employees are pald for 8 hrs work per day. 60 employees are employeed currently. Carying cost per year, divided by 4, multipled by 1,000. Baslc on negative devlation from target Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started