Answered step by step

Verified Expert Solution

Question

1 Approved Answer

14.1 Care Alliance (CA), a manufacturer of emergency care kits for disaster relief, has received the annual disaster readiness plans from its major constituents

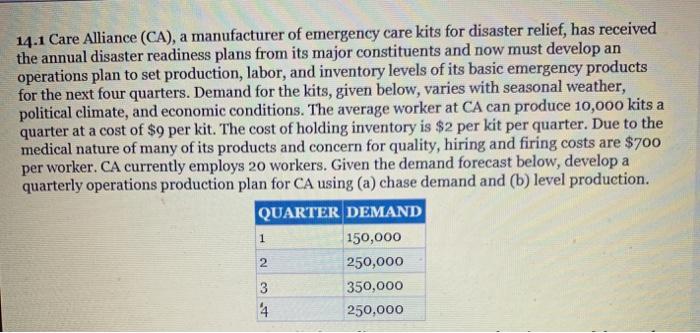

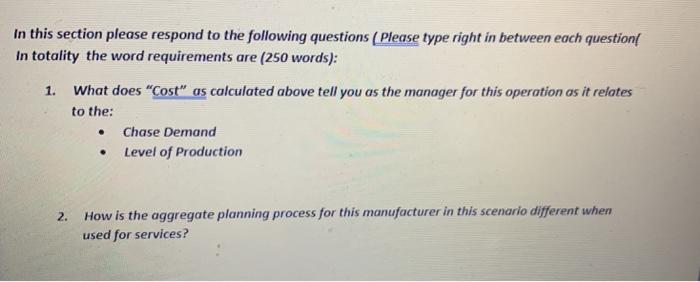

14.1 Care Alliance (CA), a manufacturer of emergency care kits for disaster relief, has received the annual disaster readiness plans from its major constituents and now must develop an operations plan to set production, labor, and inventory levels of its basic emergency products for the next four quarters. Demand for the kits, given below, varies with seasonal weather, political climate, and economic conditions. The average worker at CA can produce 10,000 kits a quarter at a cost of $9 per kit. The cost of holding inventory is $2 per kit per quarter. Due to the medical nature of many of its products and concern for quality, hiring and firing costs are $700 per worker. CA currently employs 20 workers. Given the demand forecast below, develop a quarterly operations production plan for CA using (a) chase demand and (b) level production. QUARTER DEMAND 1 150,000 2 250,000 3 350,000 4 250,000 In this section please respond to the following questions (Please type right in between each question( In totality the word requirements are (250 words): 1. What does "Cost" as calculated above tell you as the manager for this operation as it relates to the: Chase Demand 2. Level of Production How is the aggregate planning process for this manufacturer in this scenario different when used for services?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started