Answered step by step

Verified Expert Solution

Question

1 Approved Answer

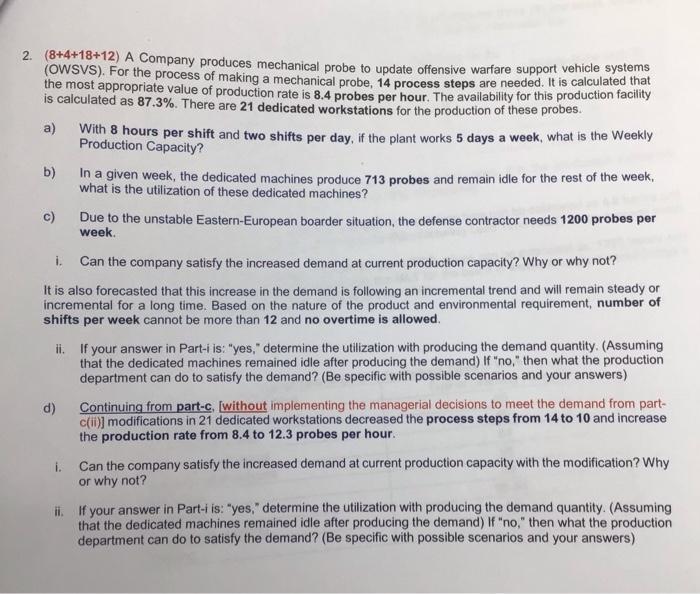

2. (8+4+18+12) A Company produces mechanical probe to update offensive warfare support vehicle systems (OWSVS). For the process of making a mechanical probe, 14

2. (8+4+18+12) A Company produces mechanical probe to update offensive warfare support vehicle systems (OWSVS). For the process of making a mechanical probe, 14 process steps are needed. It is calculated that the most appropriate value of production rate is 8.4 probes per hour. The availability for this production facility is calculated as 87.3%. There are 21 dedicated workstations for the production of these probes. a) b) In a given week, the dedicated machines produce 713 probes and remain idle for the rest of the week, what is the utilization of these dedicated machines? c) With 8 hours per shift and two shifts per day, if the plant works 5 days a week, what is the Weekly Production Capacity? Due to the unstable Eastern-European boarder situation, the defense contractor needs 1200 probes per week. i. Can the company satisfy the increased demand at current production capacity? Why or why not? It is also forecasted that this increase in the demand is following an incremental trend and will remain steady or incremental for a long time. Based on the nature of the product and environmental requirement, number of shifts per week cannot be more than 12 and no overtime is allowed. d) ii. If your answer in Part-i is: "yes," determine the utilization with producing the demand quantity. (Assuming that the dedicated machines remained idle after producing the demand) If "no," then what the production department can do to satisfy the demand? (Be specific with possible scenarios and your answers) Continuing from part-c, [without implementing the managerial decisions to meet the demand from part- c(ii)] modifications in 21 dedicated workstations decreased the process steps from 14 to 10 and increase the production rate from 8.4 to 12.3 probes per hour. i. Can the company satisfy the increased demand at current production capacity with the modification? Why or why not? ii. If your answer in Part-i is: "yes," determine the utilization with producing the demand quantity. (Assuming that the dedicated machines remained idle after producing the demand) If "no," then what the production department can do to satisfy the demand? (Be specific with possible scenarios and your answers)

Step by Step Solution

★★★★★

3.49 Rating (146 Votes )

There are 3 Steps involved in it

Step: 1

a With 8 hours per shift and two shifts per day if the plant works 5 days a week what is the Weekly Production Capacity The weekly production capacity can be calculated as follows Number of Workstatio...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started