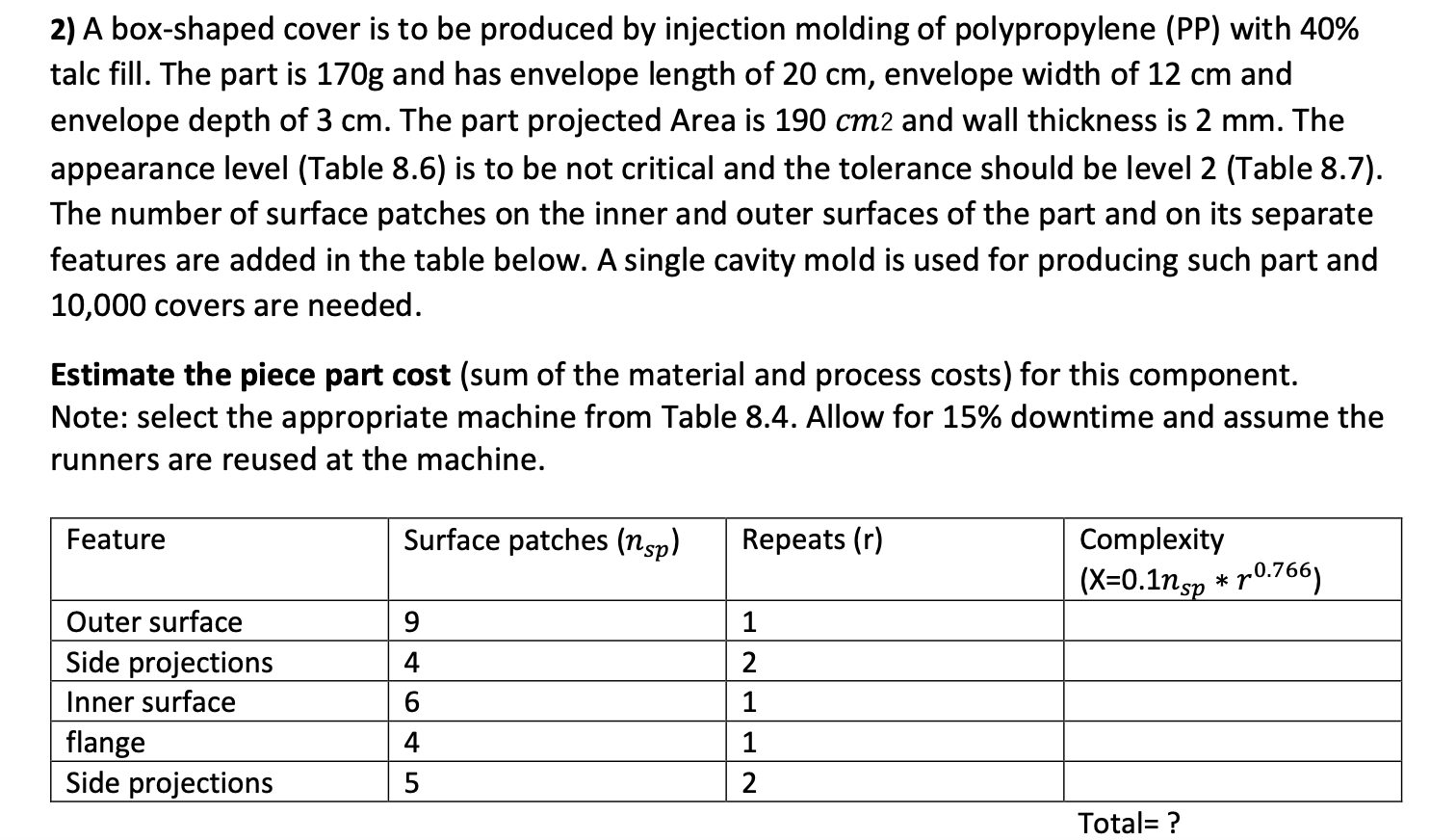

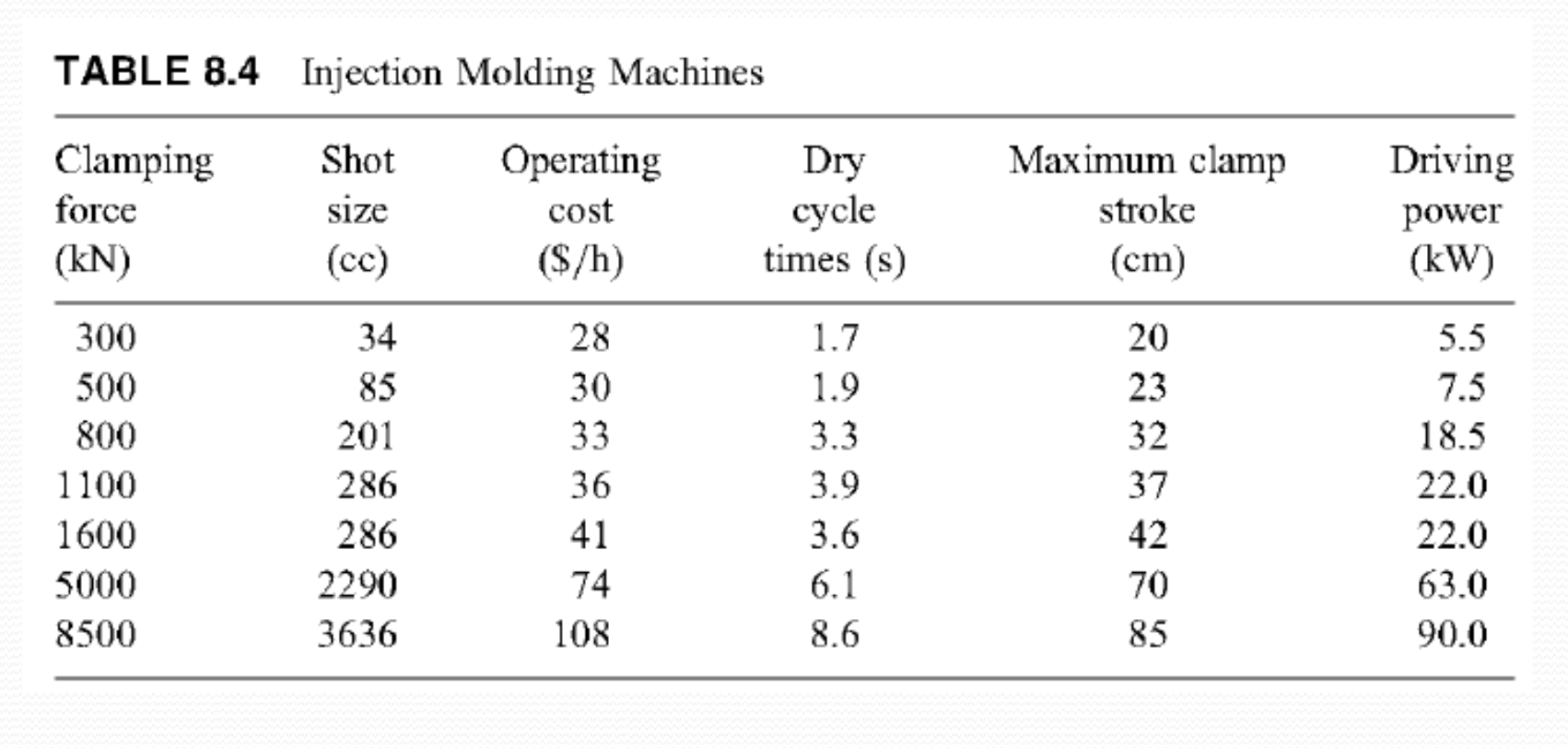

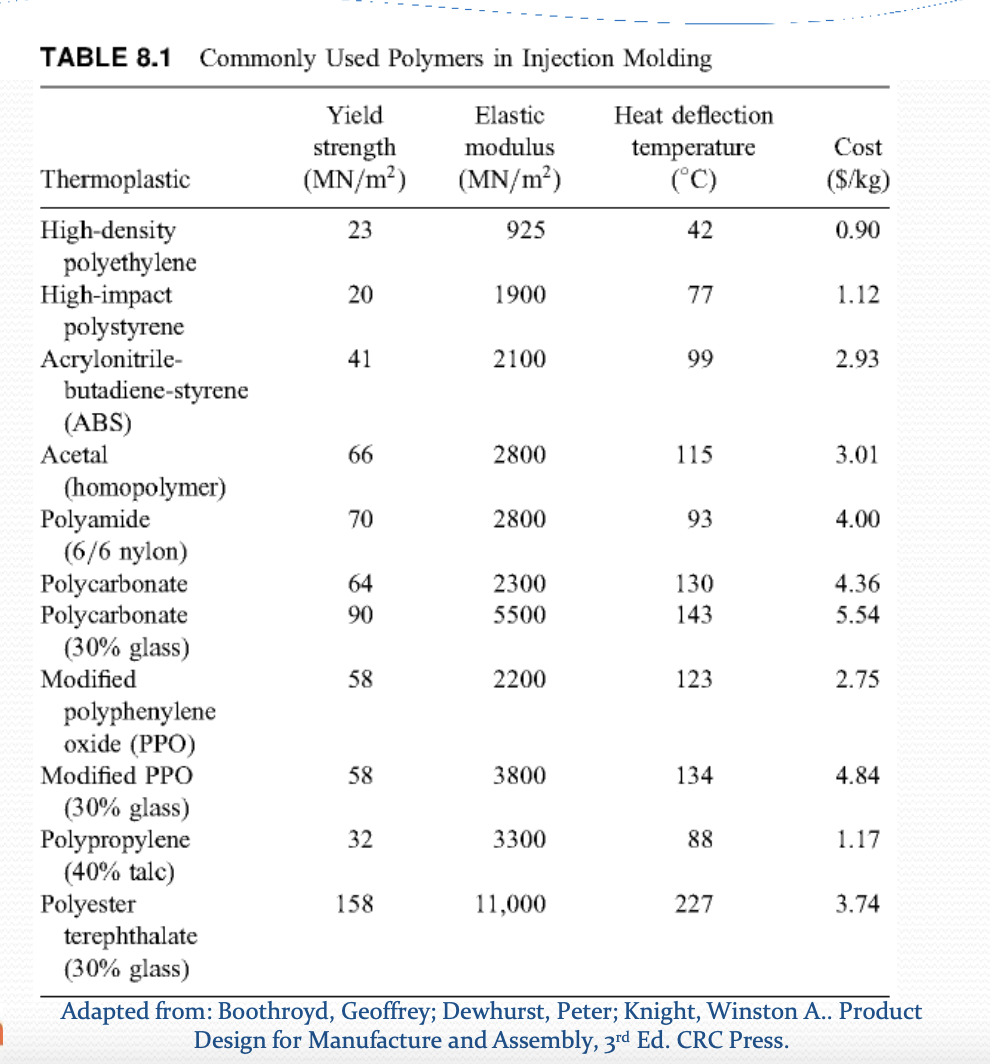

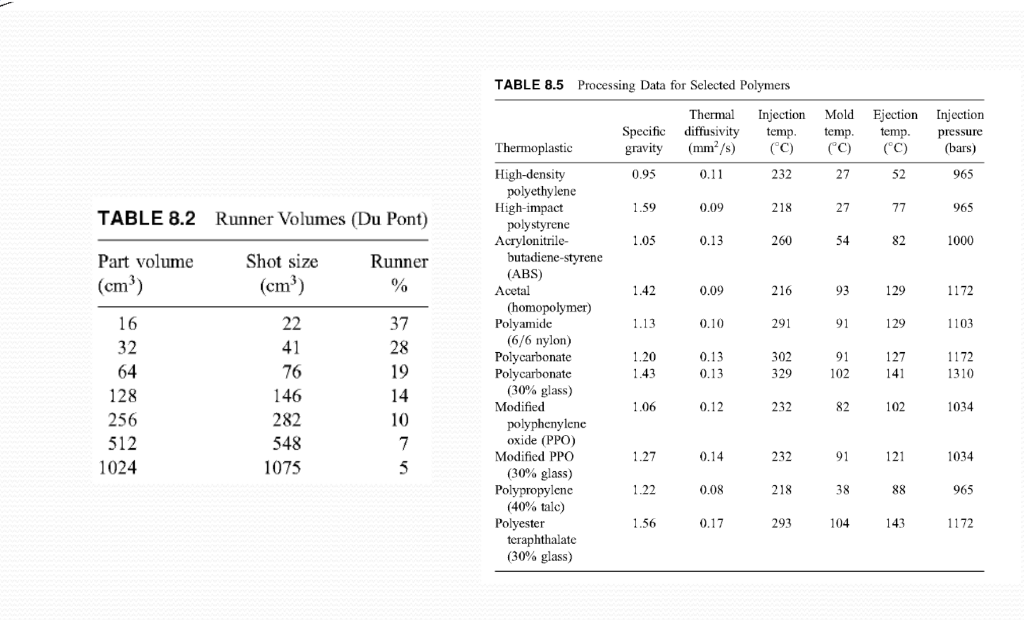

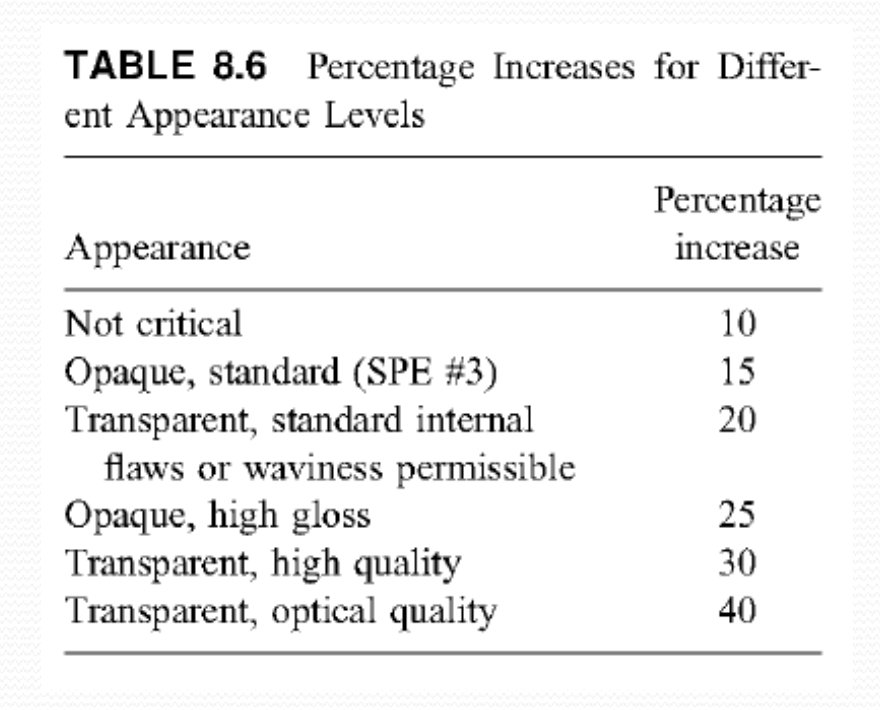

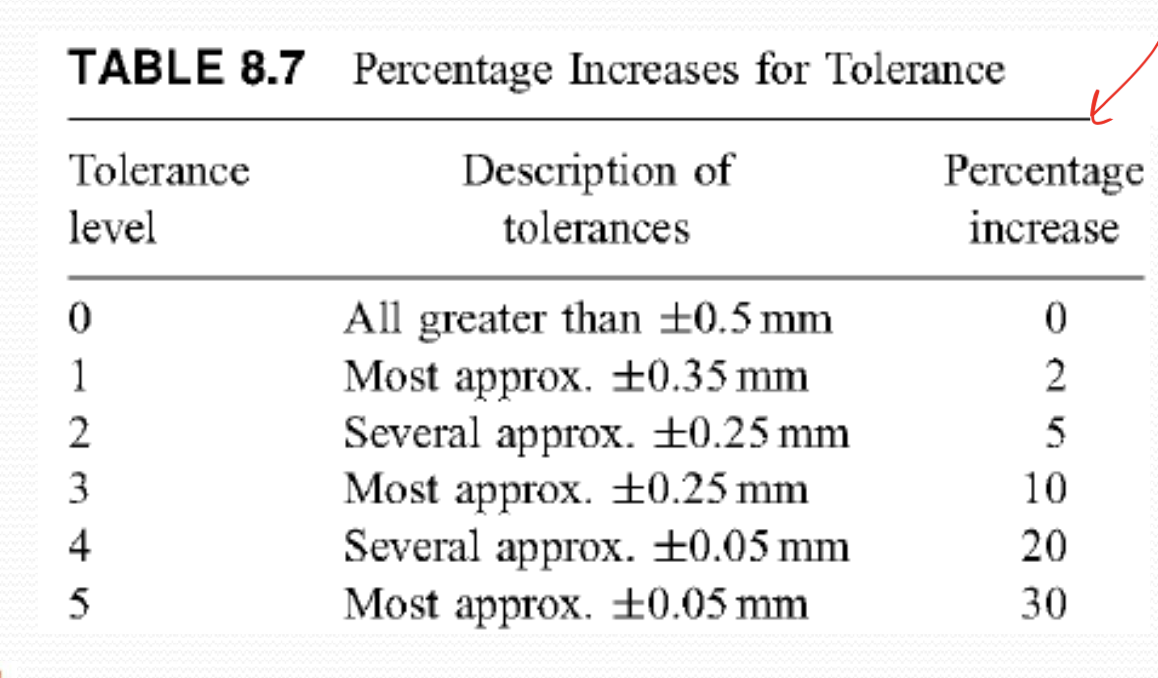

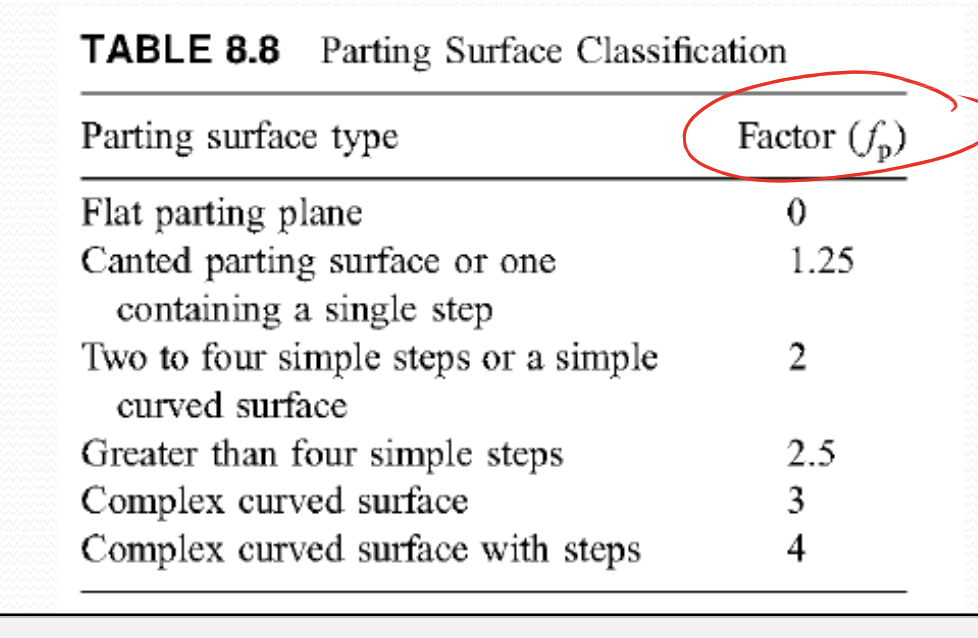

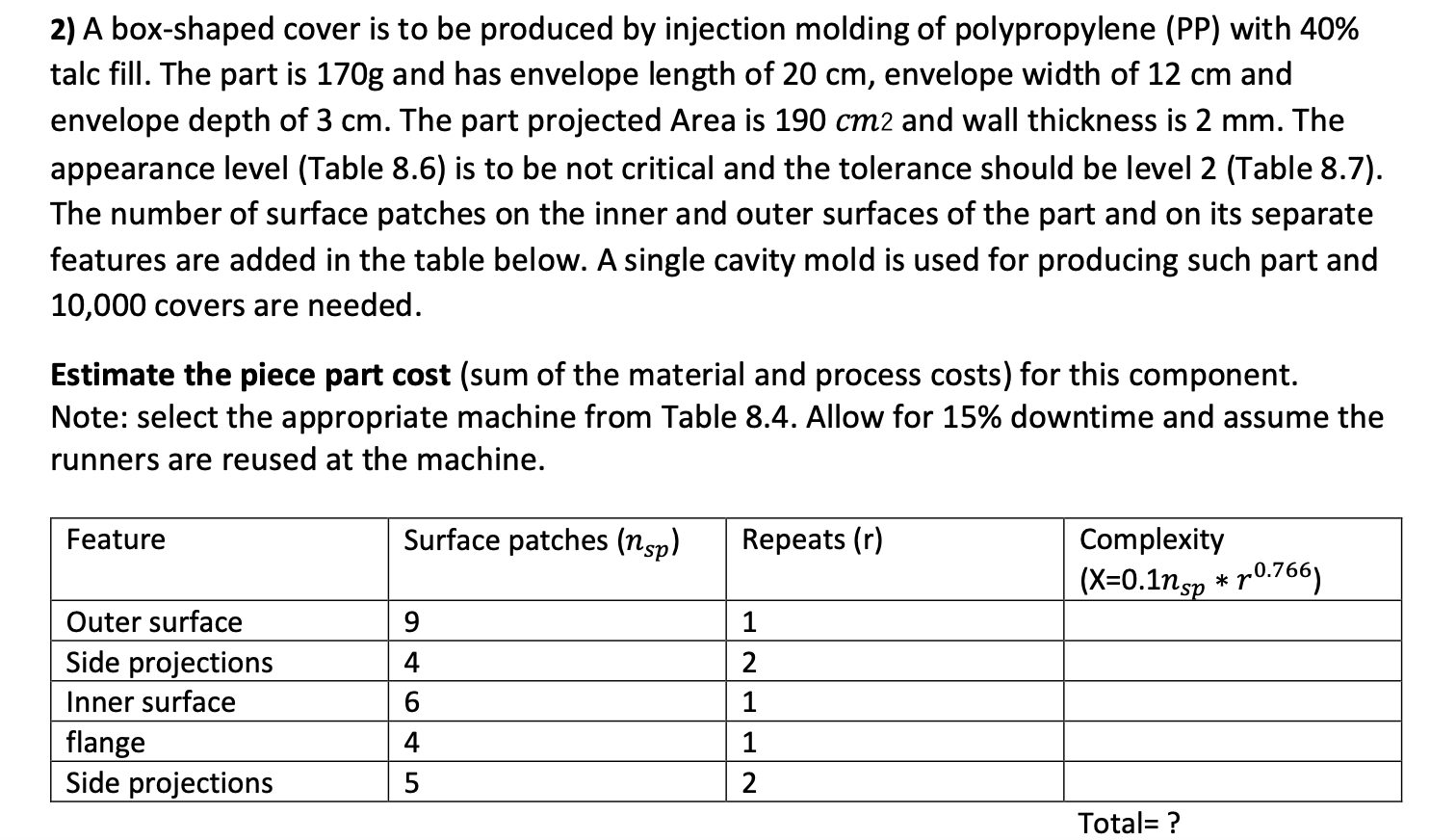

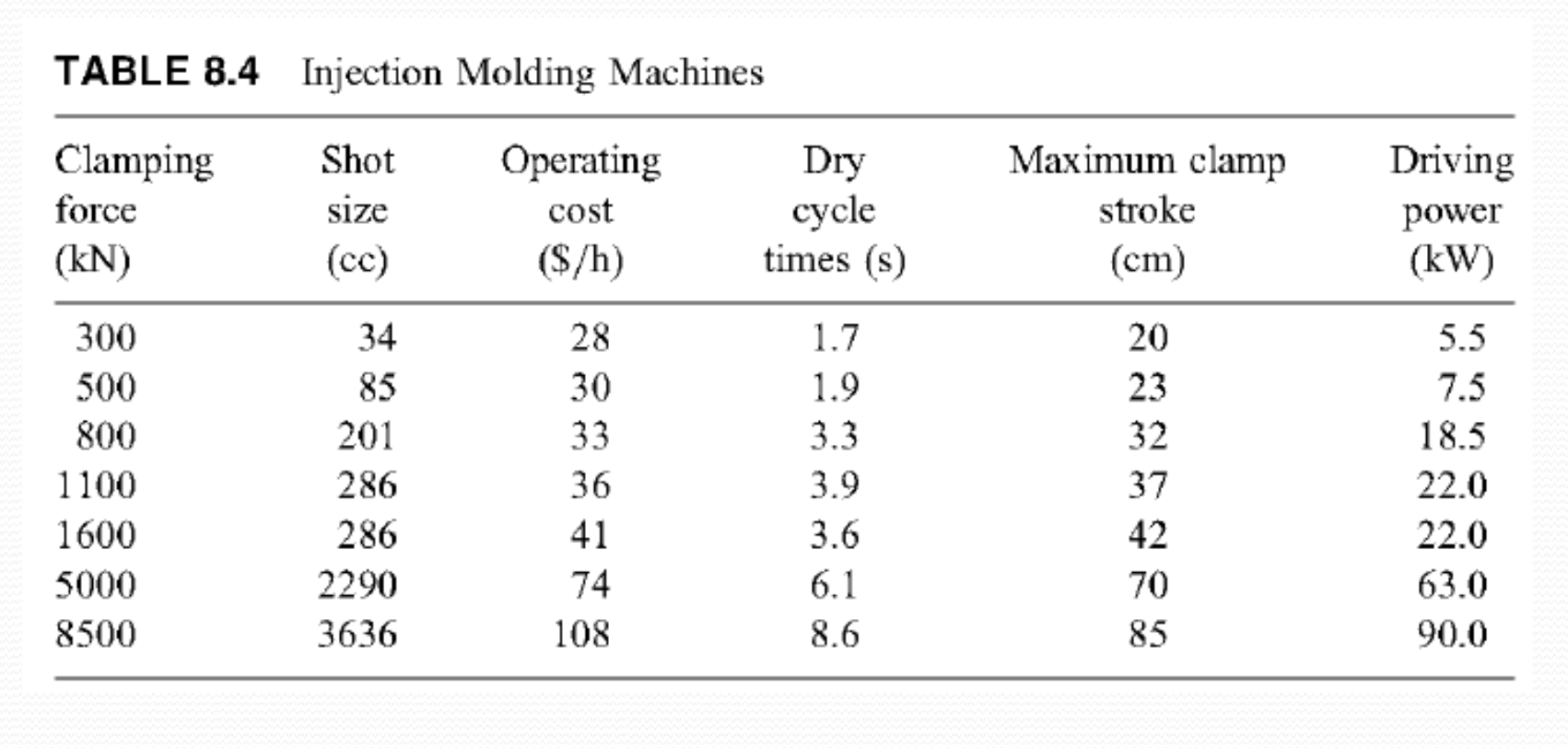

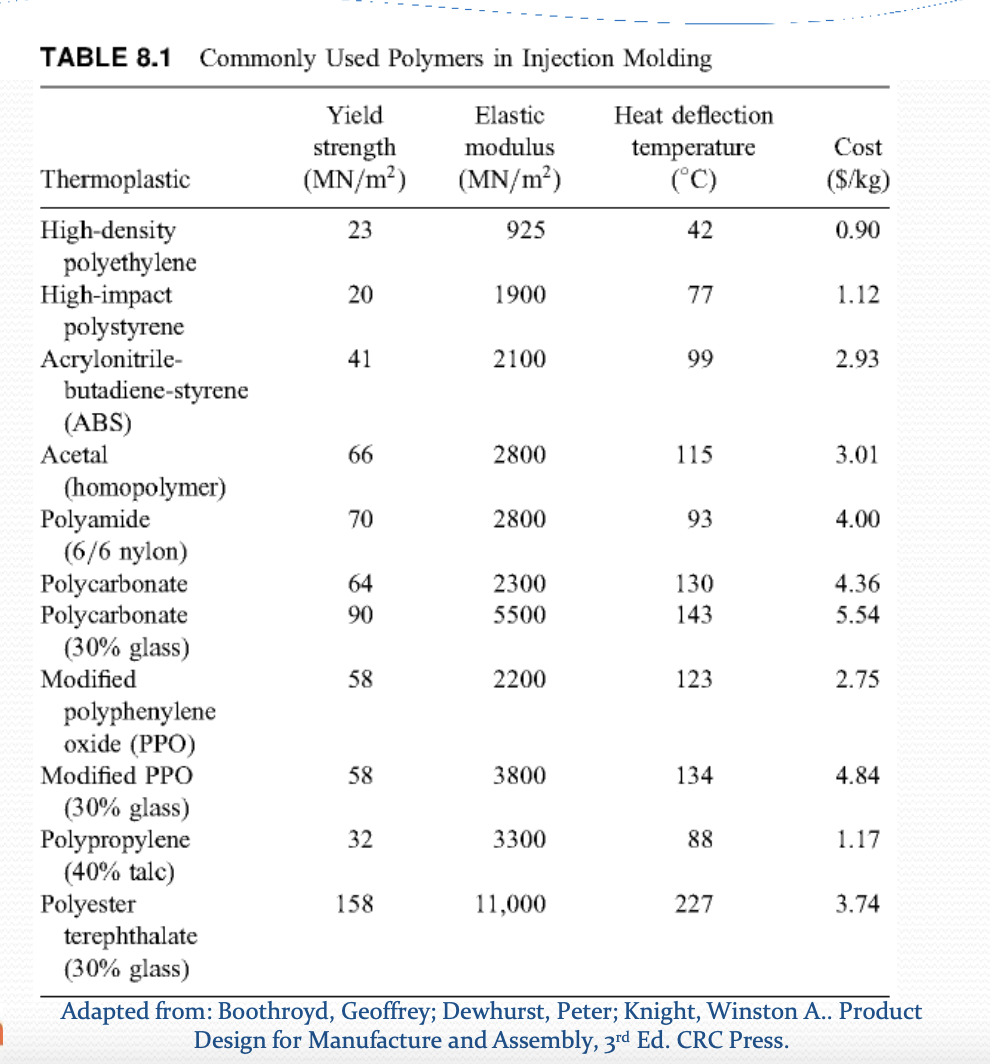

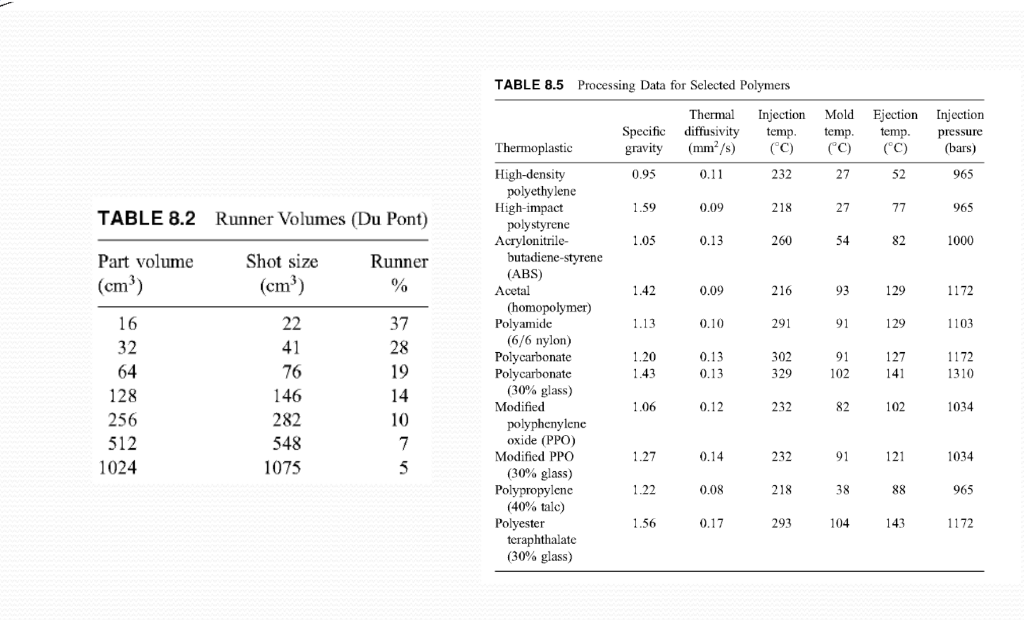

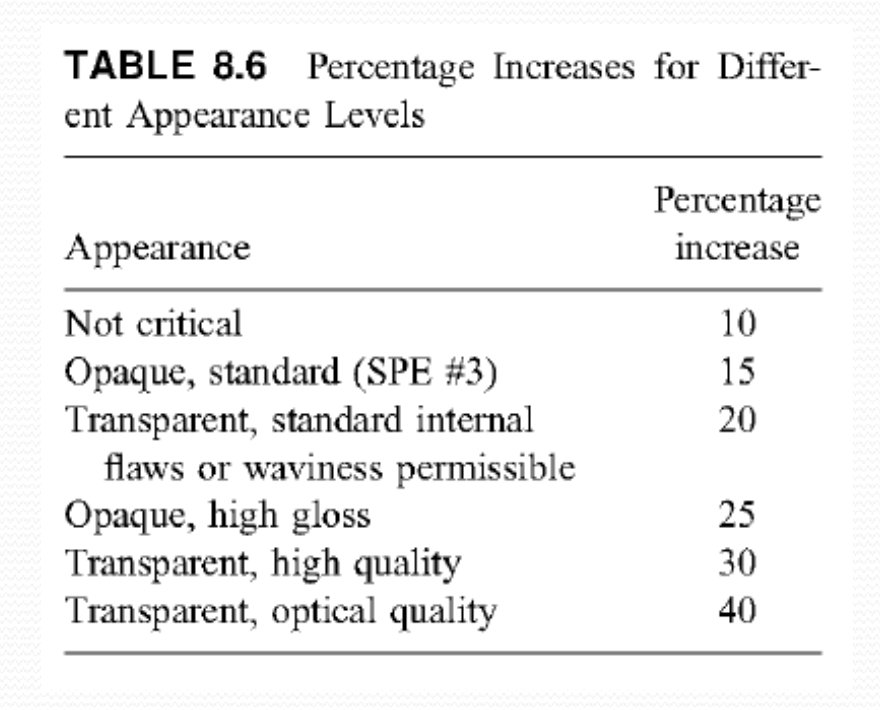

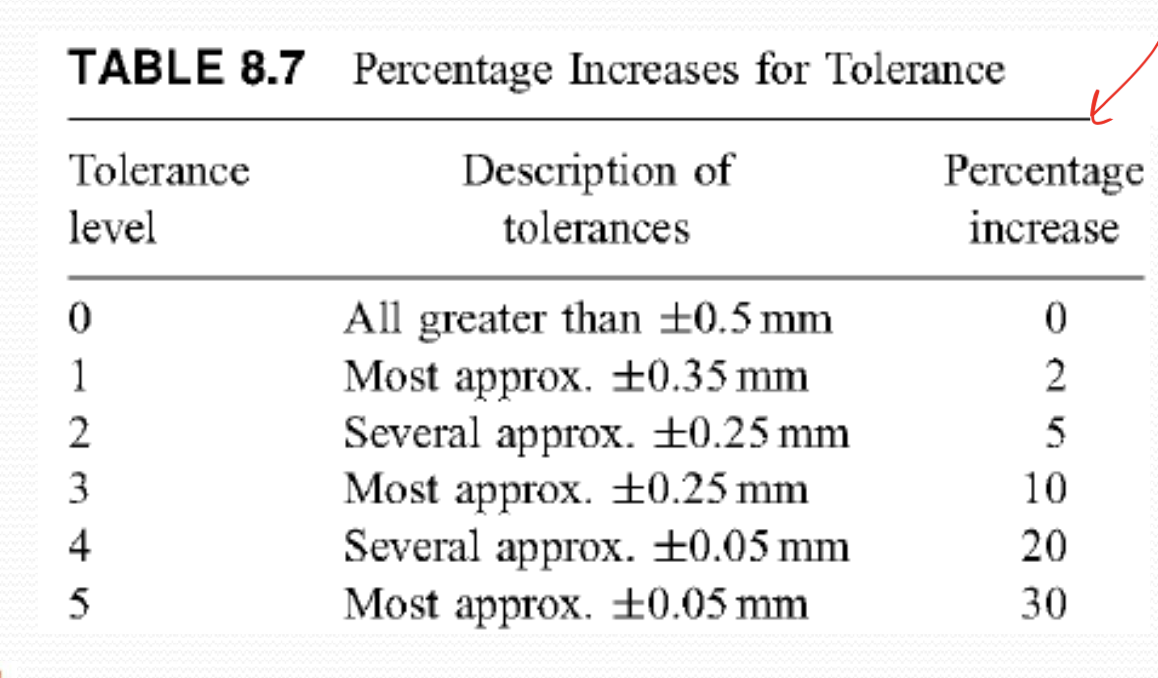

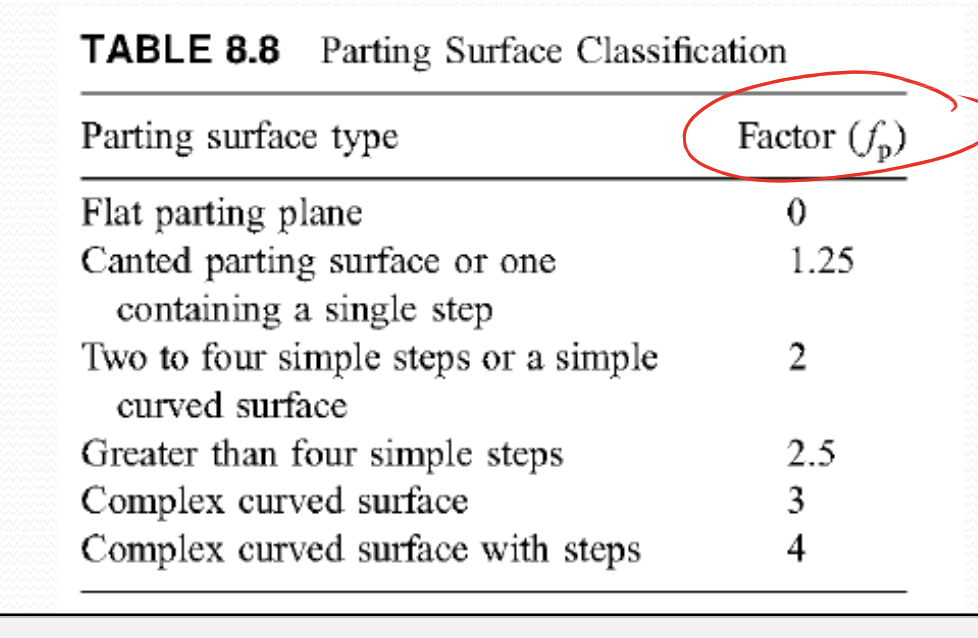

2) A box-shaped cover is to be produced by injection molding of polypropylene (PP) with 40% talc fill. The part is 170g and has envelope length of 20 cm, envelope width of 12 cm and envelope depth of 3 cm. The part projected Area is 190 cm2 and wall thickness is 2 mm. The appearance level (Table 8.6) is to be not critical and the tolerance should be level 2 (Table 8.7). The number of surface patches on the inner and outer surfaces of the part and on its separate features are added in the table below. A single cavity mold is used for producing such part and 10,000 covers are needed. Estimate the piece part cost (sum of the material and process costs) for this component. Note: select the appropriate machine from Table 8.4. Allow for 15% downtime and assume the runners are reused at the machine. Feature Surface patches (nsp) Repeats (r) Complexity (X=0.1nsp * p0.766) Outer surface Side projections Inner surface flange Side projections 4 6 1 2 1 4 1 5 2 Total= ? TABLE 8.4 Injection Molding Machines Clamping force (KN) Shot size (cc) Operating cost ($/h) Dry cycle times (S) Maximum clamp stroke (cm) Driving power (kW) 300 500 800 1100 1600 5000 8500 34 85 201 286 286 2290 3636 28 30 33 36 41 74 108 1.7 1.9 3.3 3.9 3.6 6.1 8.6 m3388 20 23 32 37 42 70 85 5.5 7.5 18.5 22.0 22.0 63.0 90.0 TABLE 8.1 Commonly Used Polymers in Injection Molding 77 Yield Elastic Heat deflection strength modulus temperature Cost Thermoplastic (MN/m) (MN/m?) (C) ($/kg) High-density 23 925 42 0.90 polyethylene High-impact 20 1900 1.12 polystyrene Acrylonitrile- 41 2100 99 2.93 butadiene-styrene (ABS) Acetal 66 2800 115 3.01 (homopolymer) Polyamide 70 2800 93 4.00 (6/6 nylon) Polycarbonate 64 2300 130 4.36 Polycarbonate 90 5500 143 5.54 (30% glass) Modified 58 2200 123 2.75 polyphenylene oxide (PPO) Modified PPO 58 3800 134 4.84 (30% glass) Polypropylene 32 3300 88 1.17 (40% talc) Polyester 158 11,000 227 3.74 terephthalate (30% glass) Adapted from: Boothroyd, Geoffrey; Dewhurst, Peter; Knight, Winston A.. Product Design for Manufacture and Assembly, 3rd Ed. CRC Press. TABLE 8.5 Processing Data for Selected Polymers Specific gravity Thermal diffusivity (mm/s) Injection temp. (C) Mold Ejection Injection temp temp. pressure (C) (C) (bars) 0.95 0.11 232 27 52 965 1.59 0.09 218 27 77 965 TABLE 8.2 Runner Volumes (Du Pont) 1.05 0.13 260 54 82 1000 Part volume (cm) Shot size (cm) Runner % (ABS) 1.42 0.09 216 93 129 1172 1.13 0.10 291 91 129 1103 1.20 1.43 0.13 0.13 Thermoplastic High-density polyethylene High-impact polystyrene Acrylonitrile- butadiene-styrene tol Acetal (homopolymer) Polyamide 6/6 nylon) Polycarbonate Polycarbonate (30% glass) Modified polyphenylene oxide (PPO) Modified PPO (30% glass) Polypropylene (40% tale) Polyester teraphthalate (30% glass) 302 329 91 102 127 141 16 32 64 128 256 512 1024 1172 1310 22 41 76 146 282 548 1075 37 28 19 14 10 7 5 1.06 0.12 232 82 102 1034 1.27 0.14 232 91 121 1034 1.22 0.08 218 38 88 965 1.56 0.17 293 104 143 1172 TABLE 8.6 Percentage Increases for Differ- ent Appearance Levels Percentage increase Appearance 10 15 20 Not critical Opaque, standard (SPE #3) Transparent, standard internal flaws or waviness permissible Opaque, high gloss Transparent, high quality Transparent, optical quality 25 30 40 TABLE 8.7 Percentage Increases for Tolerance Tolerance level Description of tolerances Percentage increase 0 0 1 2 All greater than +0.5 mm Most approx. +0.35 mm Several approx. +0.25 mm Most approx. +0.25 mm Several approx. +0.05 mm Most approx. +0.05 mm 2 5 10 3 4 20 30 5 TABLE 8.8 Parting Surface Classification Parting surface type Factor ) 0 1.25 2 Flat parting plane Canted parting surface or one containing a single step Two to four simple steps or a simple curved surface Greater than four simple steps Complex curved surface Complex curved surface with steps 2.5 3 4 2) A box-shaped cover is to be produced by injection molding of polypropylene (PP) with 40% talc fill. The part is 170g and has envelope length of 20 cm, envelope width of 12 cm and envelope depth of 3 cm. The part projected Area is 190 cm2 and wall thickness is 2 mm. The appearance level (Table 8.6) is to be not critical and the tolerance should be level 2 (Table 8.7). The number of surface patches on the inner and outer surfaces of the part and on its separate features are added in the table below. A single cavity mold is used for producing such part and 10,000 covers are needed. Estimate the piece part cost (sum of the material and process costs) for this component. Note: select the appropriate machine from Table 8.4. Allow for 15% downtime and assume the runners are reused at the machine. Feature Surface patches (nsp) Repeats (r) Complexity (X=0.1nsp * p0.766) Outer surface Side projections Inner surface flange Side projections 4 6 1 2 1 4 1 5 2 Total= ? TABLE 8.4 Injection Molding Machines Clamping force (KN) Shot size (cc) Operating cost ($/h) Dry cycle times (S) Maximum clamp stroke (cm) Driving power (kW) 300 500 800 1100 1600 5000 8500 34 85 201 286 286 2290 3636 28 30 33 36 41 74 108 1.7 1.9 3.3 3.9 3.6 6.1 8.6 m3388 20 23 32 37 42 70 85 5.5 7.5 18.5 22.0 22.0 63.0 90.0 TABLE 8.1 Commonly Used Polymers in Injection Molding 77 Yield Elastic Heat deflection strength modulus temperature Cost Thermoplastic (MN/m) (MN/m?) (C) ($/kg) High-density 23 925 42 0.90 polyethylene High-impact 20 1900 1.12 polystyrene Acrylonitrile- 41 2100 99 2.93 butadiene-styrene (ABS) Acetal 66 2800 115 3.01 (homopolymer) Polyamide 70 2800 93 4.00 (6/6 nylon) Polycarbonate 64 2300 130 4.36 Polycarbonate 90 5500 143 5.54 (30% glass) Modified 58 2200 123 2.75 polyphenylene oxide (PPO) Modified PPO 58 3800 134 4.84 (30% glass) Polypropylene 32 3300 88 1.17 (40% talc) Polyester 158 11,000 227 3.74 terephthalate (30% glass) Adapted from: Boothroyd, Geoffrey; Dewhurst, Peter; Knight, Winston A.. Product Design for Manufacture and Assembly, 3rd Ed. CRC Press. TABLE 8.5 Processing Data for Selected Polymers Specific gravity Thermal diffusivity (mm/s) Injection temp. (C) Mold Ejection Injection temp temp. pressure (C) (C) (bars) 0.95 0.11 232 27 52 965 1.59 0.09 218 27 77 965 TABLE 8.2 Runner Volumes (Du Pont) 1.05 0.13 260 54 82 1000 Part volume (cm) Shot size (cm) Runner % (ABS) 1.42 0.09 216 93 129 1172 1.13 0.10 291 91 129 1103 1.20 1.43 0.13 0.13 Thermoplastic High-density polyethylene High-impact polystyrene Acrylonitrile- butadiene-styrene tol Acetal (homopolymer) Polyamide 6/6 nylon) Polycarbonate Polycarbonate (30% glass) Modified polyphenylene oxide (PPO) Modified PPO (30% glass) Polypropylene (40% tale) Polyester teraphthalate (30% glass) 302 329 91 102 127 141 16 32 64 128 256 512 1024 1172 1310 22 41 76 146 282 548 1075 37 28 19 14 10 7 5 1.06 0.12 232 82 102 1034 1.27 0.14 232 91 121 1034 1.22 0.08 218 38 88 965 1.56 0.17 293 104 143 1172 TABLE 8.6 Percentage Increases for Differ- ent Appearance Levels Percentage increase Appearance 10 15 20 Not critical Opaque, standard (SPE #3) Transparent, standard internal flaws or waviness permissible Opaque, high gloss Transparent, high quality Transparent, optical quality 25 30 40 TABLE 8.7 Percentage Increases for Tolerance Tolerance level Description of tolerances Percentage increase 0 0 1 2 All greater than +0.5 mm Most approx. +0.35 mm Several approx. +0.25 mm Most approx. +0.25 mm Several approx. +0.05 mm Most approx. +0.05 mm 2 5 10 3 4 20 30 5 TABLE 8.8 Parting Surface Classification Parting surface type Factor ) 0 1.25 2 Flat parting plane Canted parting surface or one containing a single step Two to four simple steps or a simple curved surface Greater than four simple steps Complex curved surface Complex curved surface with steps 2.5 3 4