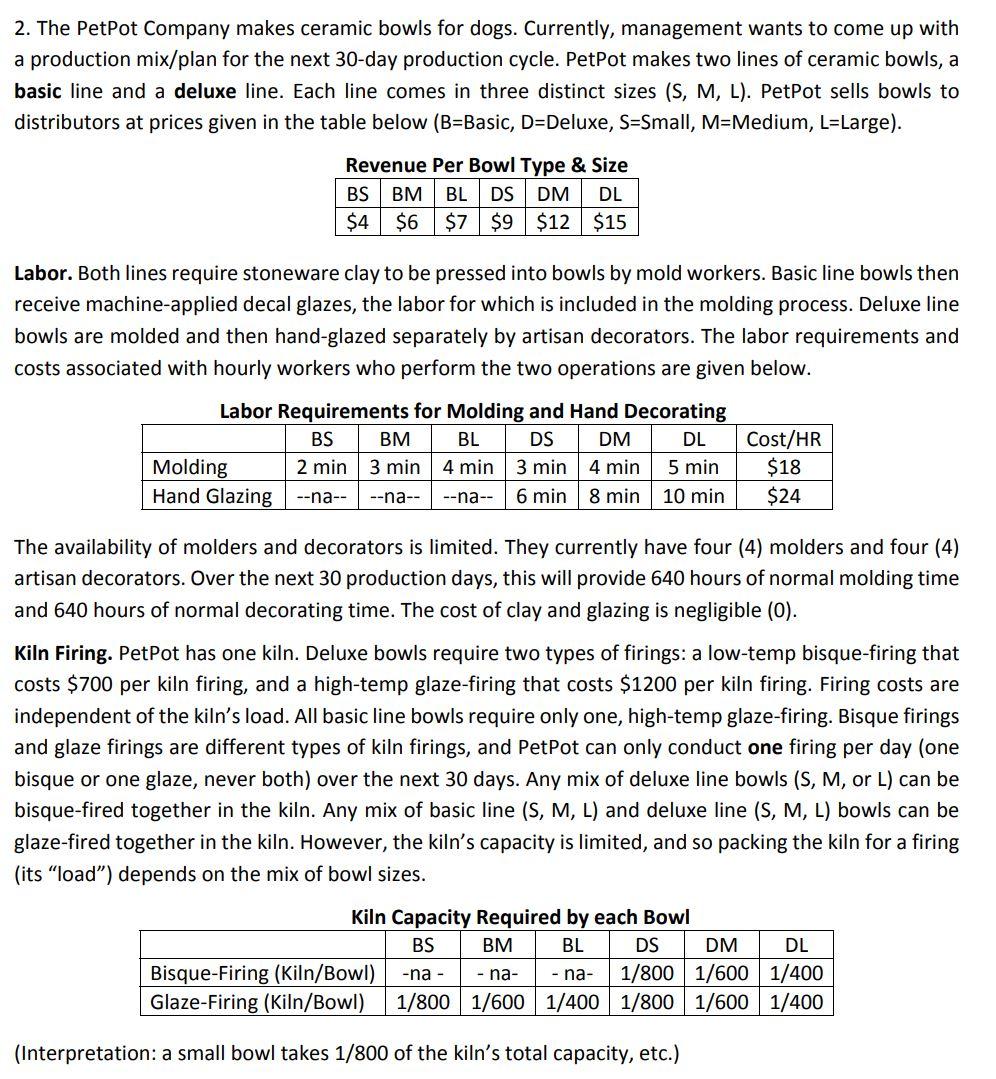

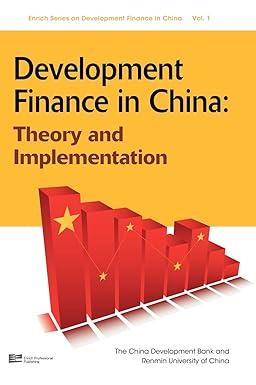

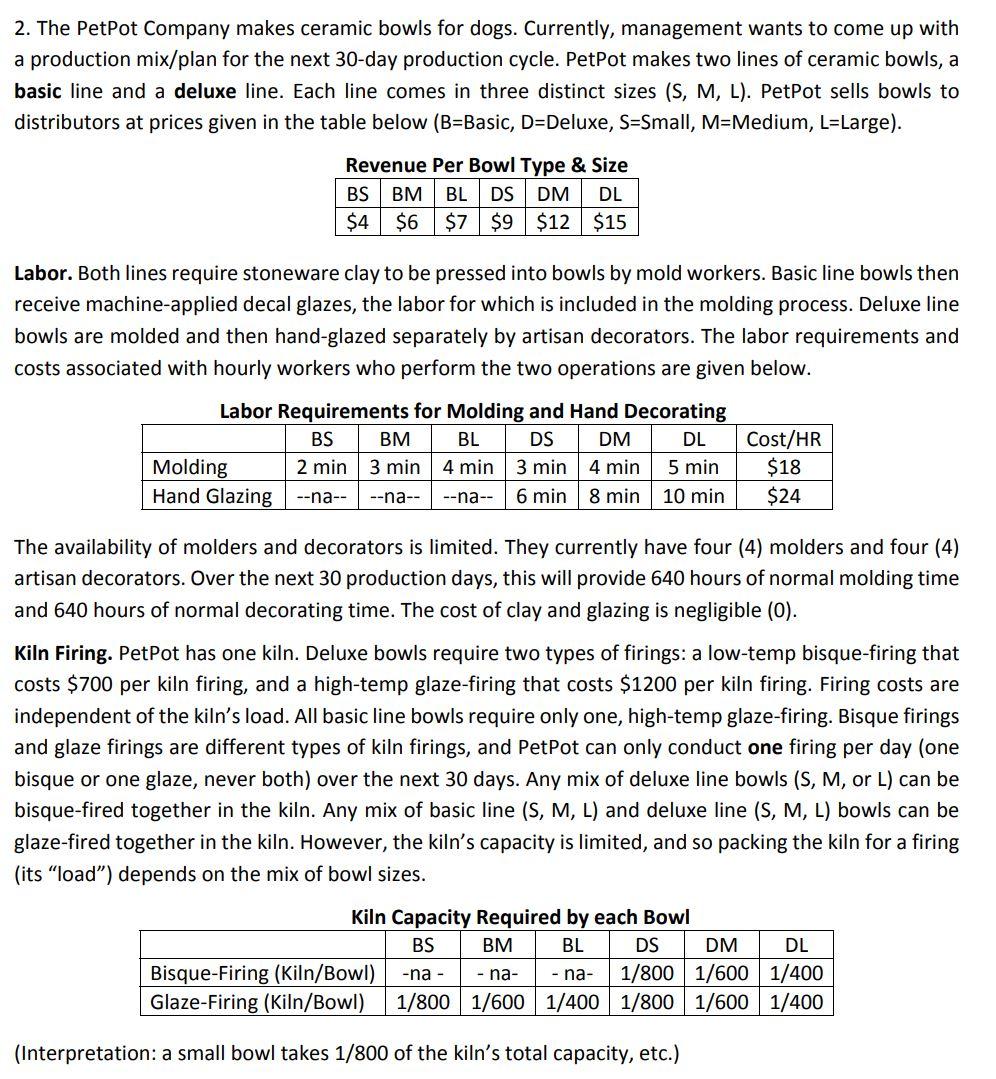

2. The PetPot Company makes ceramic bowls for dogs. Currently, management wants to come up with a production mix/plan for the next 30-day production cycle. PetPot makes two lines of ceramic bowls, a basic line and a deluxe line. Each line comes in three distinct sizes (S, M, L). PetPot sells bowls to distributors at prices given in the table below (B=Basic, D=Deluxe, S=Small, M=Medium, L=Large). Revenue Per Bowl Type & Size BS BM BL DS DM DL $4$6 $7 $9 $12 $15 Labor. Both lines require stoneware clay to be pressed into bowls by mold workers. Basic line bowls then receive machine-applied decal glazes, the labor for which is included in the molding process. Deluxe line bowls are molded and then hand-glazed separately by artisan decorators. The labor requirements and costs associated with hourly workers who perform the two operations are given below. Labor Requirements for Molding and Hand Decorating BS BM BL DS DM DL Molding 2 min 3 min 4 min 3 min 4 min 5 min Hand Glazing --na-- --na-- --na-- 6 min 8 min 10 min Cost/HR $18 $24 The availability of molders and decorators is limited. They currently have four (4) molders and four (4) artisan decorators. Over the next 30 production days, this will provide 640 hours of normal molding time and 640 hours of normal decorating time. The cost of clay and glazing is negligible (0). Kiln Firing. PetPot has one kiln. Deluxe bowls require two types of firings: a low-temp bisque-firing that costs $700 per kiln firing, and a high-temp glaze-firing that costs $1200 per kiln firing. Firing costs are independent of the kiln's load. All basic line bowls require only one, high-temp glaze-firing. Bisque firings and glaze firings are different types of kiln firings, and PetPot can only conduct one firing per day (one bisque or one glaze, never both) over the next 30 days. Any mix of deluxe line bowls (S, M, or L) can be bisque-fired together in the kiln. Any mix of basic line (S, M, L) and deluxe line (S, M, L) bowls can be glaze-fired together in the kiln. However, the kiln's capacity is limited, and so packing the kiln for a firing (its "load") depends on the mix of bowl sizes. Kiln Capacity Required by each Bowl BS BM BL DS DM DL Bisque-Firing (Kiln/Bowl) -na- -na- -na- 1/800 1/600 1/400 Glaze-Firing (Kiln/Bowl) 1/800 1/600 1/400 1/800 1/600 1/400 (Interpretation: a small bowl takes 1/800 of the kiln's total capacity, etc.) Demand. PetPot is so popular right now they can sell all the bowls they produce. Managerial Production Requirements. PetPot managers have decided that total production of small bowls (basic plus deluxe combined) cannot exceed 5000 bowls; the total production of medium bowls (basic plus deluxe combined) cannot exceed 4000 bowls; and total production of large bowls (basic plus deluxe combined) cannot exceed 3500 bowls. Additionally, at least 750 deluxe bowls of each size (S, M, and L) must be made to meet existing backorders and grow the deluxe line brand. Questions (submit answers in your exam booklet at the end) (a) Formulate and write out an integer linear program in its entirety) that will develop the required 30- day production mix/plan. Hints: Start with decision variables BS, BM, BL, DS, DM, DL (= number of bowls of each type/size) and add additional decision variables as necessary. Approach the constraints one block at a time. Your objective function coefficients will require some arithmetic calculations. (b) Solve your formulation in Excel. Use 1% for your optimality gap in SOLVER. Indicate the optimal net contribution (profit) as well as the optimal production plan. (c) Suppose PetPot could pay mold workers time and a half ($18 + $9 = $27) to work overtime hours. They anticipate they could add up to 80 extra hours of molding time over the next 30 days by offering overtime pay. Adjust your formulation in part (b) to include this overtime option. Write out the new objective function and any constraints that change in your formulation of part a. (d) Re-solve your model in Excel and report your findings. How many additional overtime molding hours would PetPot want to pay for, if any? What is the new production plan? Use 1% for your optimality gap in SOLVER 2. The PetPot Company makes ceramic bowls for dogs. Currently, management wants to come up with a production mix/plan for the next 30-day production cycle. PetPot makes two lines of ceramic bowls, a basic line and a deluxe line. Each line comes in three distinct sizes (S, M, L). PetPot sells bowls to distributors at prices given in the table below (B=Basic, D=Deluxe, S=Small, M=Medium, L=Large). Revenue Per Bowl Type & Size BS BM BL DS DM DL $4$6 $7 $9 $12 $15 Labor. Both lines require stoneware clay to be pressed into bowls by mold workers. Basic line bowls then receive machine-applied decal glazes, the labor for which is included in the molding process. Deluxe line bowls are molded and then hand-glazed separately by artisan decorators. The labor requirements and costs associated with hourly workers who perform the two operations are given below. Labor Requirements for Molding and Hand Decorating BS BM BL DS DM DL Molding 2 min 3 min 4 min 3 min 4 min 5 min Hand Glazing --na-- --na-- --na-- 6 min 8 min 10 min Cost/HR $18 $24 The availability of molders and decorators is limited. They currently have four (4) molders and four (4) artisan decorators. Over the next 30 production days, this will provide 640 hours of normal molding time and 640 hours of normal decorating time. The cost of clay and glazing is negligible (0). Kiln Firing. PetPot has one kiln. Deluxe bowls require two types of firings: a low-temp bisque-firing that costs $700 per kiln firing, and a high-temp glaze-firing that costs $1200 per kiln firing. Firing costs are independent of the kiln's load. All basic line bowls require only one, high-temp glaze-firing. Bisque firings and glaze firings are different types of kiln firings, and PetPot can only conduct one firing per day (one bisque or one glaze, never both) over the next 30 days. Any mix of deluxe line bowls (S, M, or L) can be bisque-fired together in the kiln. Any mix of basic line (S, M, L) and deluxe line (S, M, L) bowls can be glaze-fired together in the kiln. However, the kiln's capacity is limited, and so packing the kiln for a firing (its "load") depends on the mix of bowl sizes. Kiln Capacity Required by each Bowl BS BM BL DS DM DL Bisque-Firing (Kiln/Bowl) -na- -na- -na- 1/800 1/600 1/400 Glaze-Firing (Kiln/Bowl) 1/800 1/600 1/400 1/800 1/600 1/400 (Interpretation: a small bowl takes 1/800 of the kiln's total capacity, etc.) Demand. PetPot is so popular right now they can sell all the bowls they produce. Managerial Production Requirements. PetPot managers have decided that total production of small bowls (basic plus deluxe combined) cannot exceed 5000 bowls; the total production of medium bowls (basic plus deluxe combined) cannot exceed 4000 bowls; and total production of large bowls (basic plus deluxe combined) cannot exceed 3500 bowls. Additionally, at least 750 deluxe bowls of each size (S, M, and L) must be made to meet existing backorders and grow the deluxe line brand. Questions (submit answers in your exam booklet at the end) (a) Formulate and write out an integer linear program in its entirety) that will develop the required 30- day production mix/plan. Hints: Start with decision variables BS, BM, BL, DS, DM, DL (= number of bowls of each type/size) and add additional decision variables as necessary. Approach the constraints one block at a time. Your objective function coefficients will require some arithmetic calculations. (b) Solve your formulation in Excel. Use 1% for your optimality gap in SOLVER. Indicate the optimal net contribution (profit) as well as the optimal production plan. (c) Suppose PetPot could pay mold workers time and a half ($18 + $9 = $27) to work overtime hours. They anticipate they could add up to 80 extra hours of molding time over the next 30 days by offering overtime pay. Adjust your formulation in part (b) to include this overtime option. Write out the new objective function and any constraints that change in your formulation of part a. (d) Re-solve your model in Excel and report your findings. How many additional overtime molding hours would PetPot want to pay for, if any? What is the new production plan? Use 1% for your optimality gap in SOLVER