Question

(1) The tensile test data given in the table provided in the excel file attached corresponds to a tensile test of a low-carbon steel, with

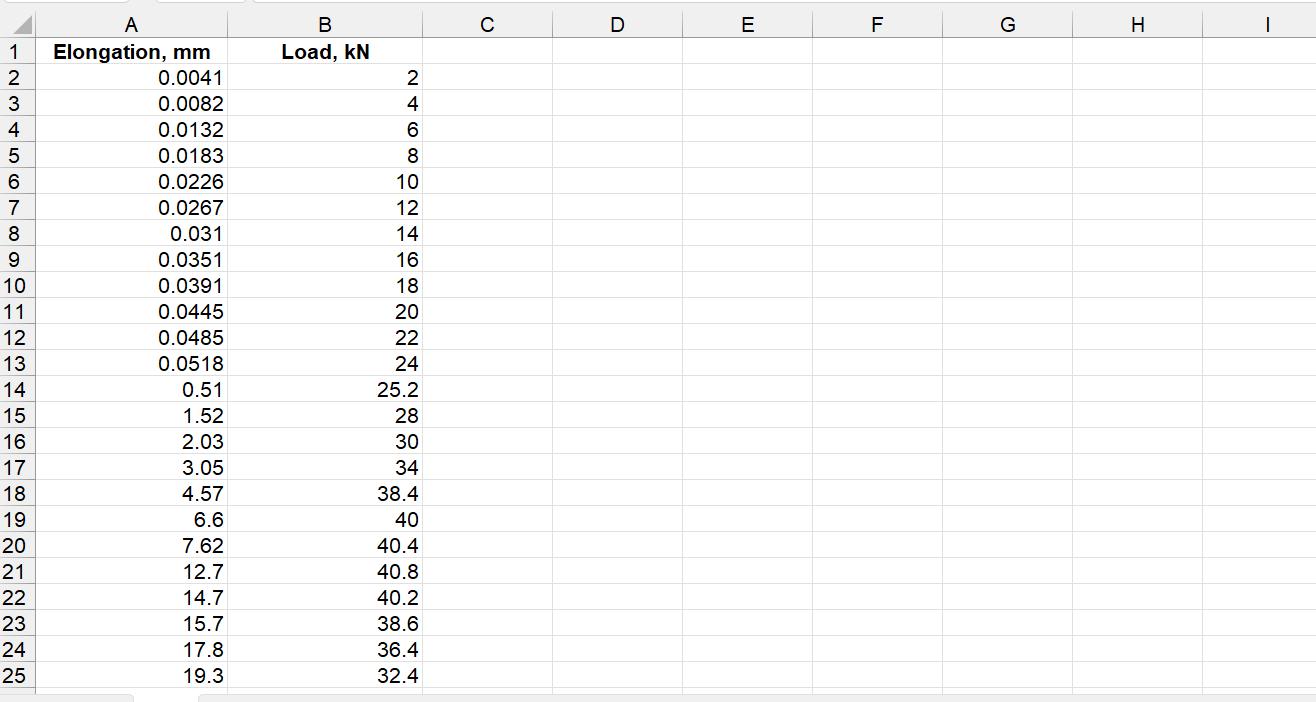

(1) The tensile test data given in the table provided in the excel file attached corresponds to a tensile test of a low-carbon steel, with a specimen having 12 mm diameter and 50 mm gage length. Breaking load, 27.2 kN; final gage length, 72.8 mm; final diameter, 6.3 mm.

(1.1) Plot the engineering stress-strain curve.

(1.2) Determine the: Modulus of elasticity, upper yield point, 0.2% yield stress, tensile strength, fracture stress, percentage of elongation, percentage of reduction of area.

(1.3) Plot the true stress-strain curve up to maximum load.

(1.4) Determine the value of the plastic modulus (KH) and the strain-hardening exponent (nH) of Hollomon´s work-hardening law.

(1.5) Compare the experimental and predicted true curves.

A 1 Elongation, mm 0.0041 0.0082 0.0132 0.0183 0.0226 0.0267 0.031 0.0351 0.0391 0.0445 0.0485 0.0518 2345678 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 0.51 1.52 2.03 3.05 4.57 6.6 7.62 12.7 14.7 15.7 17.8 19.3 B Load, KN 246BONNERENNE 8 10 12 14 16 18 20 22 25.2 28 30 34 38.4 40 O4 40.4 40.8 40.2 38.6 36.4 32.4 C D E F H

Step by Step Solution

3.49 Rating (146 Votes )

There are 3 Steps involved in it

Step: 1

11 Plot the engineering stressstrain curve The engineering stressstrain curve is plotted by dividing the load by the original gage area d24 and the el...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started