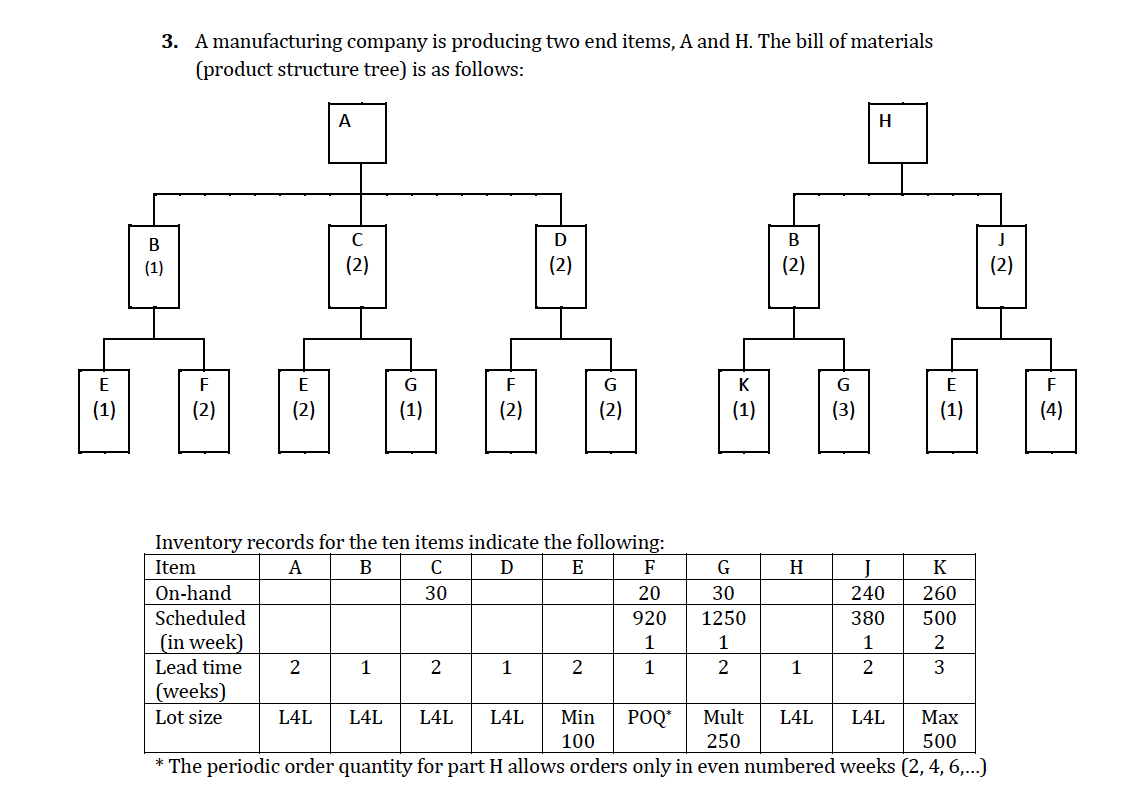

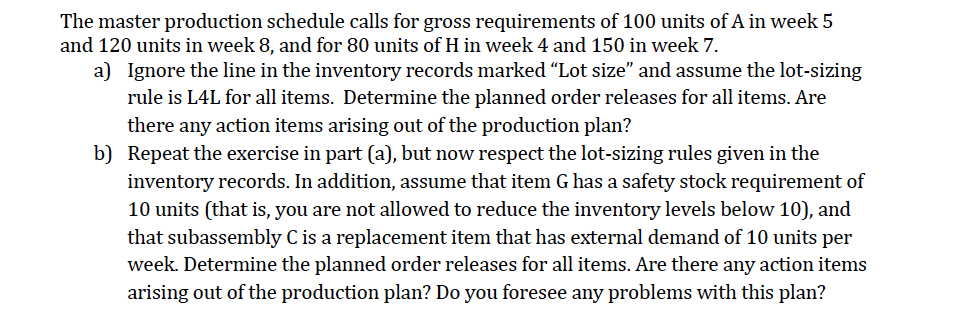

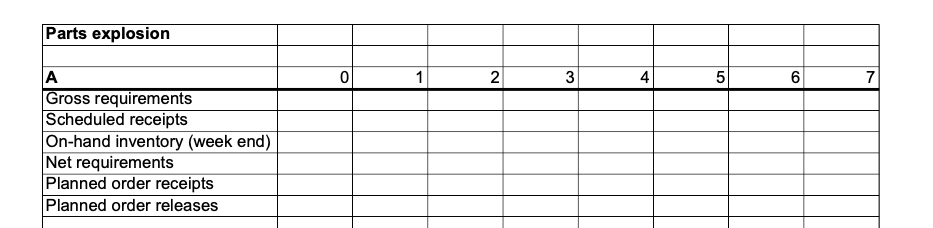

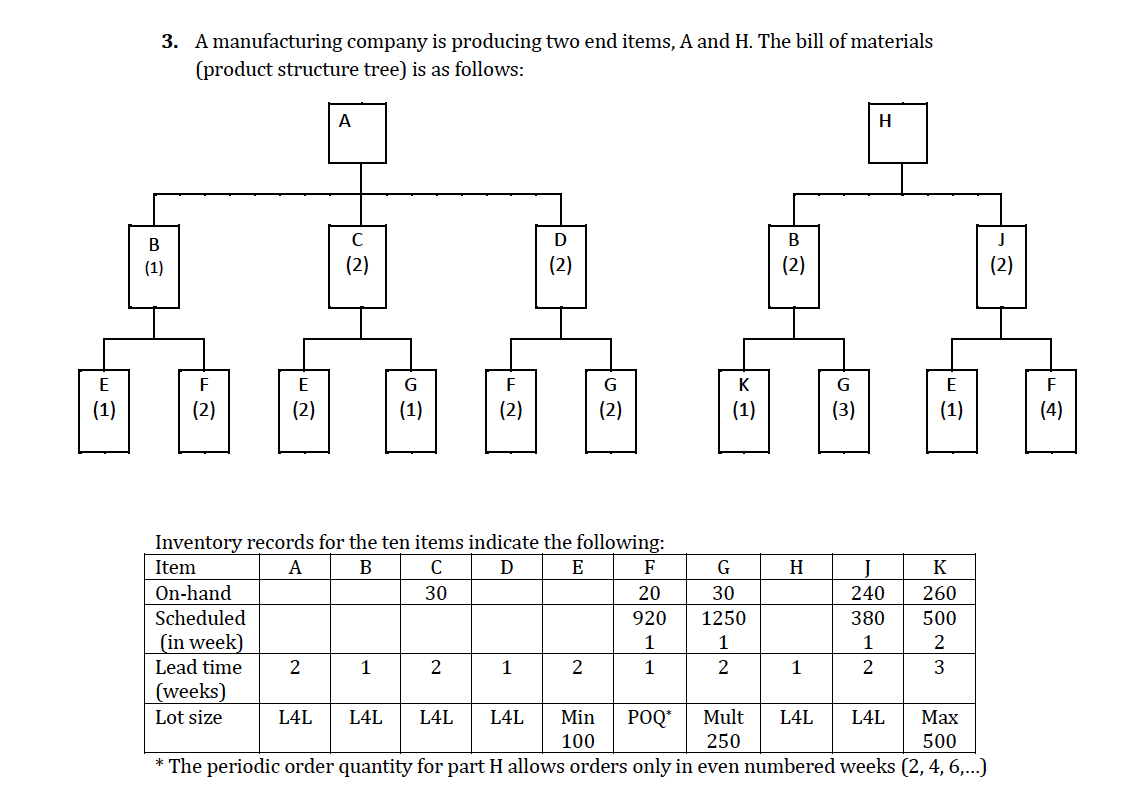

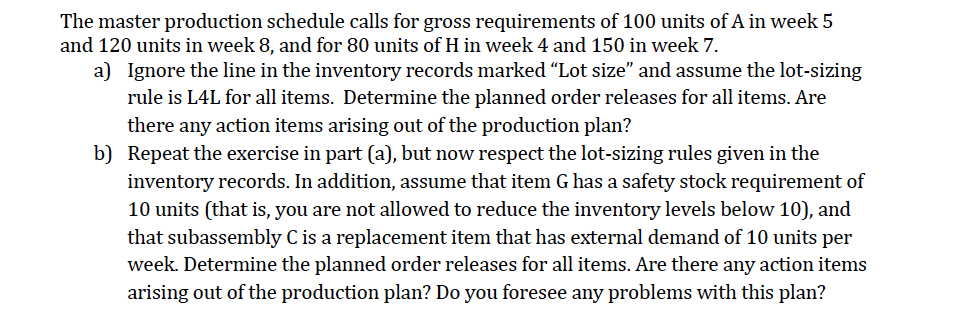

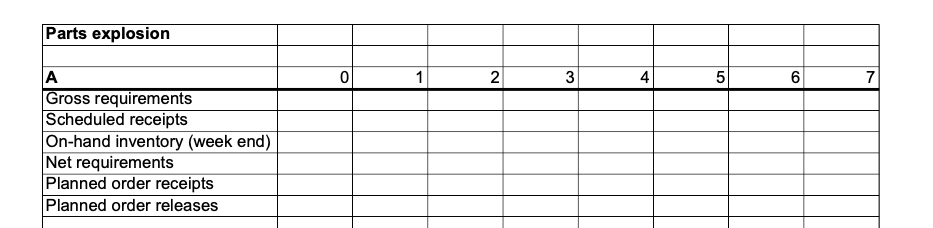

3. A manufacturing company is producing two end items, A and H. The bill of materials (product structure tree) is as follows: 2 BOOOOOO wa 30 Inventory records for the ten items indicate the following: Item A B C D E F G H I K On-hand 20 30 240 260 Scheduled 920 1250 380500 (in week) 1 / 1 1 / 2 Lead time 1 2 1 2 1 2 1 2 1 2 3 (weeks Lot size L4L | L4L | L4L | L4L Min POQ" | Mult | L4L | L4L | Max 100 250 500 * The periodic order quantity for part H allows orders only in even numbered weeks (2, 4, 6,...) The master production schedule calls for gross requirements of 100 units of A in week 5 and 120 units in week 8, and for 80 units of H in week 4 and 150 in week 7. a) Ignore the line in the inventory records marked "Lot size" and assume the lot-sizing rule is L4L for all items. Determine the planned order releases for all items. Are there any action items arising out of the production plan? b) Repeat the exercise in part (a), but now respect the lot-sizing rules given in the inventory records. In addition, assume that item G has a safety stock requirement of 10 units (that is, you are not allowed to reduce the inventory levels below 10), and that subassembly Cis a replacement item that has external demand of 10 units per week. Determine the planned order releases for all items. Are there any action items arising out of the production plan? Do you foresee any problems with this plan? Parts explosion 0 12 Gross requirements Scheduled receipts On-hand inventory (week end) Net requirements Planned order receipts Planned order releases 3. A manufacturing company is producing two end items, A and H. The bill of materials (product structure tree) is as follows: 2 BOOOOOO wa 30 Inventory records for the ten items indicate the following: Item A B C D E F G H I K On-hand 20 30 240 260 Scheduled 920 1250 380500 (in week) 1 / 1 1 / 2 Lead time 1 2 1 2 1 2 1 2 1 2 3 (weeks Lot size L4L | L4L | L4L | L4L Min POQ" | Mult | L4L | L4L | Max 100 250 500 * The periodic order quantity for part H allows orders only in even numbered weeks (2, 4, 6,...) The master production schedule calls for gross requirements of 100 units of A in week 5 and 120 units in week 8, and for 80 units of H in week 4 and 150 in week 7. a) Ignore the line in the inventory records marked "Lot size" and assume the lot-sizing rule is L4L for all items. Determine the planned order releases for all items. Are there any action items arising out of the production plan? b) Repeat the exercise in part (a), but now respect the lot-sizing rules given in the inventory records. In addition, assume that item G has a safety stock requirement of 10 units (that is, you are not allowed to reduce the inventory levels below 10), and that subassembly Cis a replacement item that has external demand of 10 units per week. Determine the planned order releases for all items. Are there any action items arising out of the production plan? Do you foresee any problems with this plan? Parts explosion 0 12 Gross requirements Scheduled receipts On-hand inventory (week end) Net requirements Planned order receipts Planned order releases