Answered step by step

Verified Expert Solution

Question

1 Approved Answer

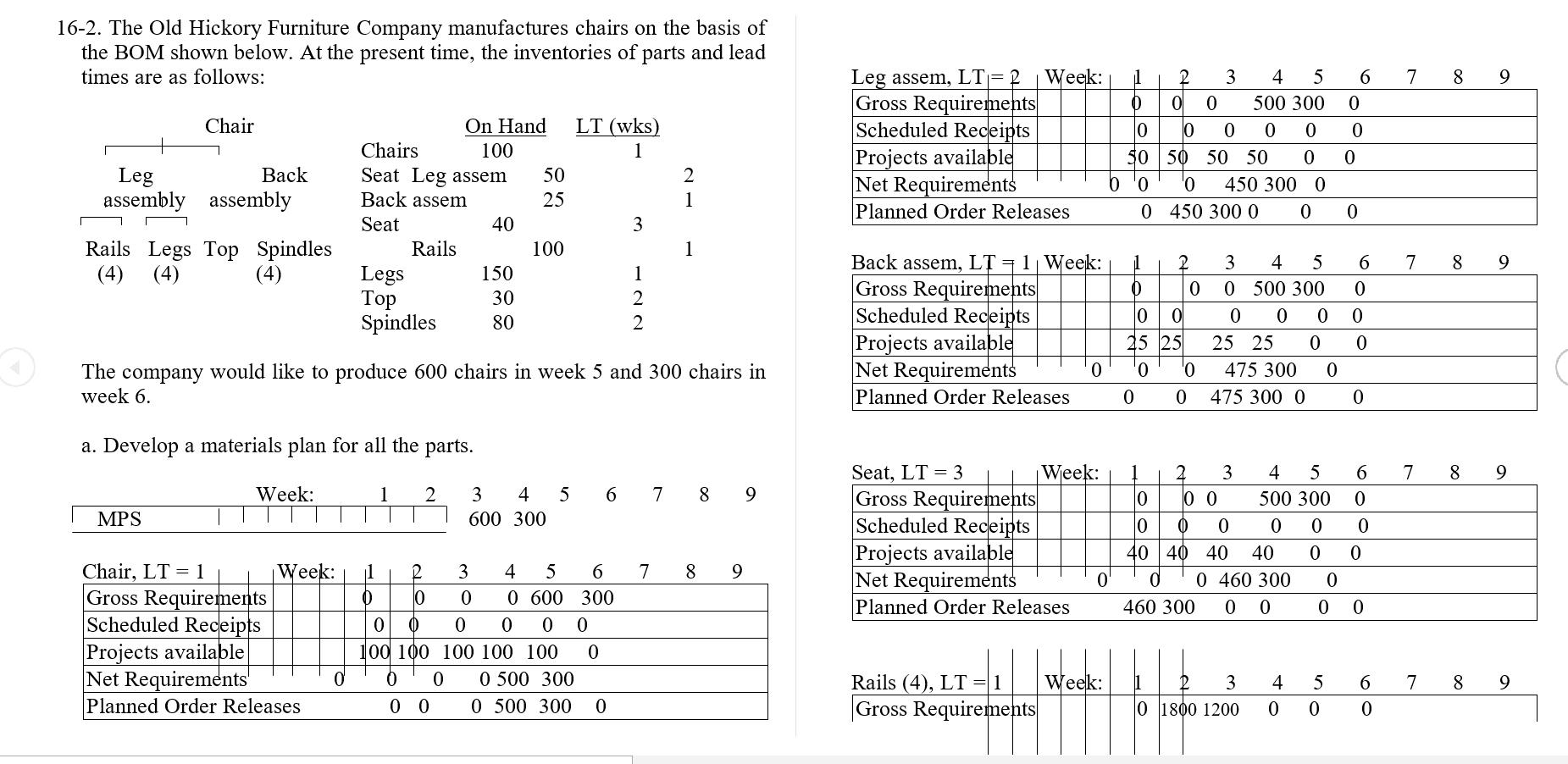

4 16-2. The Old Hickory Furniture Company manufactures chairs on the basis of the BOM shown below. At the present time, the inventories of

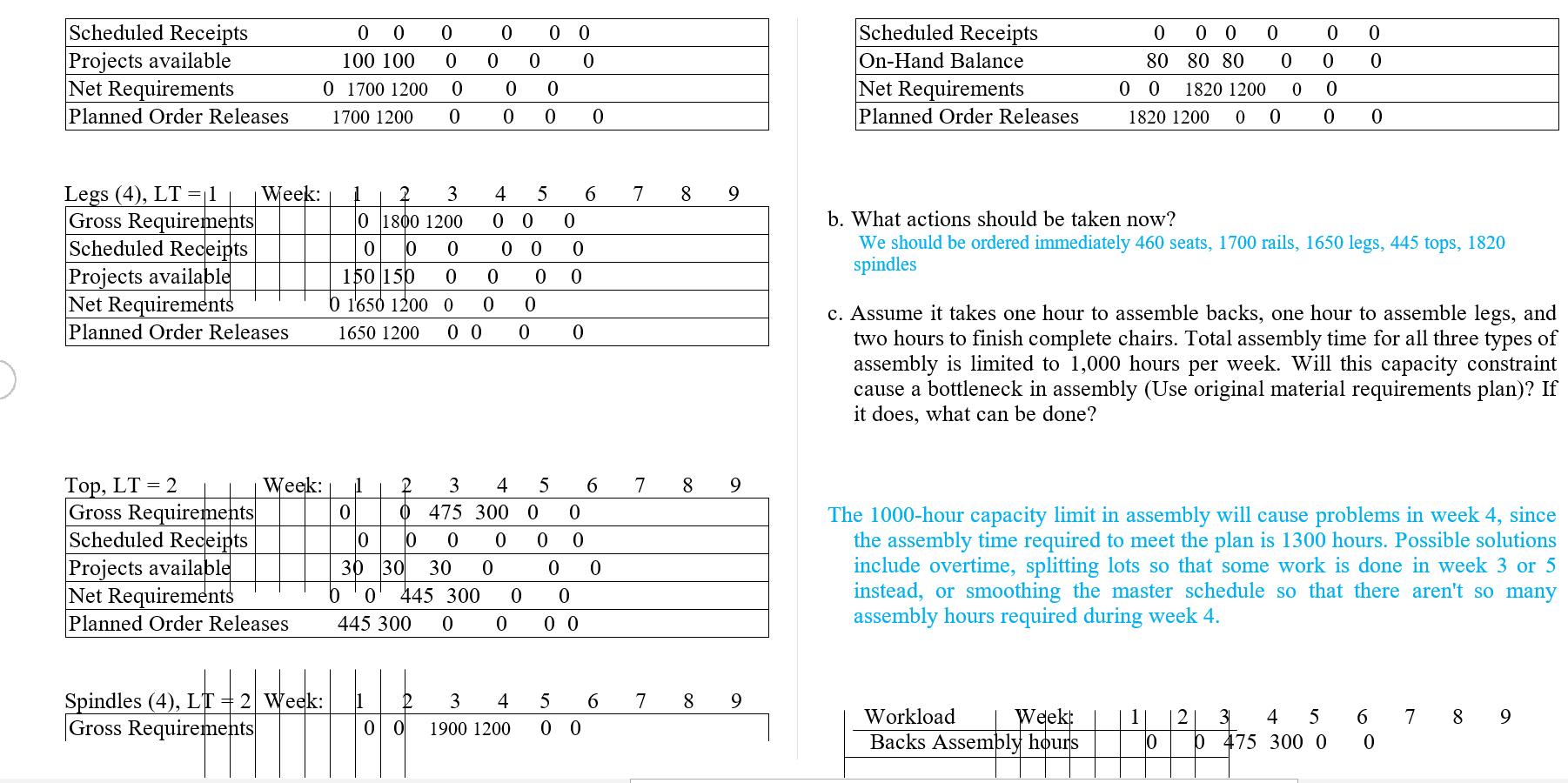

4 16-2. The Old Hickory Furniture Company manufactures chairs on the basis of the BOM shown below. At the present time, the inventories of parts and lead times are as follows: Chair Leg Back assembly assembly Rails Legs Top Spindles (4) (4) (4) MPS Week: Chair, LT = 1 Gross Requirements a. Develop a materials plan for all the parts. 1 2 Week: Scheduled Receipts Projects available Net Requirements Planned Order Releases Chairs Seat Leg assem Back assem Seat 0 Rails Legs Top Spindles 1 0 AL The company would like to produce 600 chairs in week 5 and 300 chairs in week 6. 0 On Hand 100 0 0 8 00 40 3 150 30 80 0 50 25 100 3 4 600 300 0 100 100 100 100 100 LT (wks) 1 4 5 0 600 0 0 0 0 0 500 300 6 300 3 5 6 7 8 0 122 0 500 300 0 2 1 1 7 8 9 9 Leg assem, LT=2 Gross Requirements Scheduled Receipts Projects available Net Requirements Planned Order Releases Week: Back assem, LT 1 Week: Gross Requirements Scheduled Receipts Projects available Net Requirements Planned Order Releases Seat, LT= 3 Gross Requirements Scheduled Receipts Projects available Net Requirements Planned Order Releases 0 Week: 0 Rails (4), LT-1 Week: Gross Requirements H 0 '0 1 0 0 10 50 50 3 4 5 500 300 0 0 50 50 0 0 450 300 0 0 2 0 0 0 0 450 300 0 2 0 10 25 25 0 '0 '0 0 0 2 3 0 0 0 25 25 0 0 475 300 475 300 0 460 300 4 5 500 300 3 0 0 0 40 40 40 40 0 0 460 300 00 1 2 3 0 1800 1200 4 5 500 300 0 4 0 0 0 0 5 0 0 6 0 0 0 6 0 0 0 0 0 0 0 0 0 6 0 0 0 6 0 7 7 7 7 8 9 8 9 8 9 8 9 Scheduled Receipts Projects available Net Requirements Planned Order Releases Legs (4), LT=1 Gross Requirements Scheduled Receipts Projects available Net Requirements Planned Order Releases 0 0 100 100 0 1700 1200 1700 1200 Week: 1 0 Top, LT=2 Gross Requirements Scheduled Receipts Projects available Net Requirements Planned Order Releases Week: Spindles (4), LT=2 Week: Gross Requirements 0 10 150 150 0 1650 1200 1650 1200 0 0 2 0 0 0 0 0 2 3 4 1800 1200 0 0 0 0 0 0 00 0 0 0 0 0 0 0 0 3 4 1900 1200 0 0 0 0 3 4 0475 300 0 0 10 0 0 0 30 30 30 0 0 0 445 300 445 300 0 00 0 0 0 5 5 0 0 0 0 0 0 0 5 00 0 6 0 0 0 00 6 7 7 6 7 8 8 8 9 9 Scheduled Receipts On-Hand Balance Net Requirements Planned Order Releases 0 00 0 80 80 80 0 00 1820 1200 1820 1200 0 0 0 0 Workload Week: Backs Assembly hours 0 0 0 0 b. What actions should be taken now? We should be ordered immediately 460 seats, 1700 rails, 1650 legs, 445 tops, 1820 spindles 0 0 c. Assume it takes one hour to assemble backs, one hour to assemble legs, and two hours to finish complete chairs. Total assembly time for all three types of assembly is limited to 1,000 hours per week. Will this capacity constraint cause a bottleneck in assembly (Use original material requirements plan)? If it does, what can be done? 0 The 1000-hour capacity limit in assembly will cause problems in week 4, since the assembly time required to meet the plan is 1300 hours. Possible solutions include overtime, splitting lots so that some work is done in week 3 or 5 instead, or smoothing the master schedule so that there aren't so many assembly hours required during week 4. 2 31 4 5 0 475 300 0 6 7 8 9 0 LegsAssembly Finish Chairs Assembly 0 Total Assembly 0 0 450 300 00 0 1000600 0 0 450 775 1300 600 0 0 d. What is the effect of changing the master schedule to 300 chairs in week 5 and 400 chairs in week 6? Using the assumptions in part(c) balances the assembly hours required so that now 150 hours are required in week 2, 575 in week 3, and 800 each in weeks 4 and 5. This plan would solve the problem in week 4 in assembly. E. Assume the 80 spindles in stock could not be located anywhere in the company. 1. What changes would occur to the plan 2. What actions would be needed?

Step by Step Solution

★★★★★

3.33 Rating (159 Votes )

There are 3 Steps involved in it

Step: 1

a The materials plan for all parts is shown low alrs Gross Requirements Onh...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started