Answered step by step

Verified Expert Solution

Question

1 Approved Answer

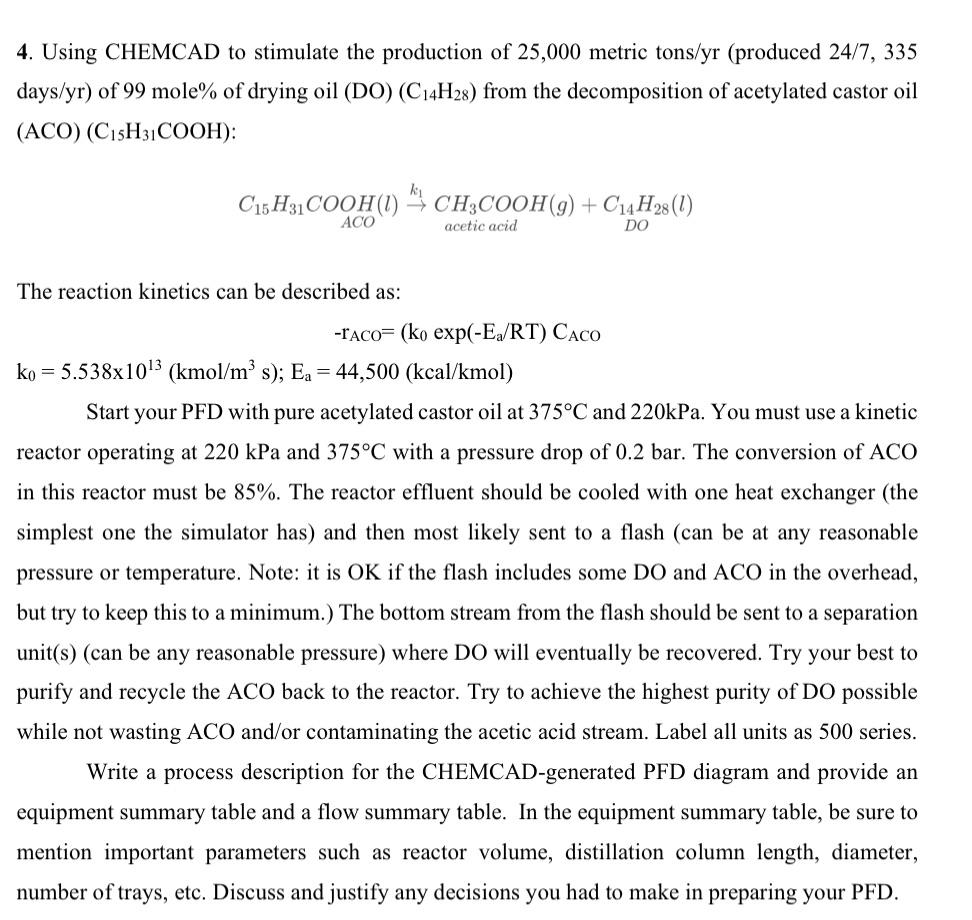

4. Using CHEMCAD to stimulate the production of 25,000 metric tons/yr (produced 24/7, 335 days/yr) of 99 mole% of drying oil (DO) (C14H28) from

4. Using CHEMCAD to stimulate the production of 25,000 metric tons/yr (produced 24/7, 335 days/yr) of 99 mole% of drying oil (DO) (C14H28) from the decomposition of acetylated castor oil (ACO) (C15H31COOH): C15H31 COOH (1) ky CH3COOH (g) + C14 H28 (1) ACO acetic acid DO The reaction kinetics can be described as: -TACO (ko exp(-Ea/RT) CACO ko 5.538x10 (kmol/m s); Ea = 44,500 (kcal/kmol) Start your PFD with pure acetylated castor oil at 375C and 220kPa. You must use a kinetic reactor operating at 220 kPa and 375C with a pressure drop of 0.2 bar. The conversion of ACO in this reactor must be 85%. The reactor effluent should be cooled with one heat exchanger (the simplest one the simulator has) and then most likely sent to a flash (can be at any reasonable pressure or temperature. Note: it is OK if the flash includes some DO and ACO in the overhead, but try to keep this to a minimum.) The bottom stream from the flash should be sent to a separation unit(s) (can be any reasonable pressure) where DO will eventually be recovered. Try your best to purify and recycle the ACO back to the reactor. Try to achieve the highest purity of DO possible while not wasting ACO and/or contaminating the acetic acid stream. Label all units as 500 series. Write a process description for the CHEMCAD-generated PFD diagram and provide an equipment summary table and a flow summary table. In the equipment summary table, be sure to mention important parameters such as reactor volume, distillation column length, diameter, number of trays, etc. Discuss and justify any decisions you had to make in preparing your PFD.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started