Answered step by step

Verified Expert Solution

Question

1 Approved Answer

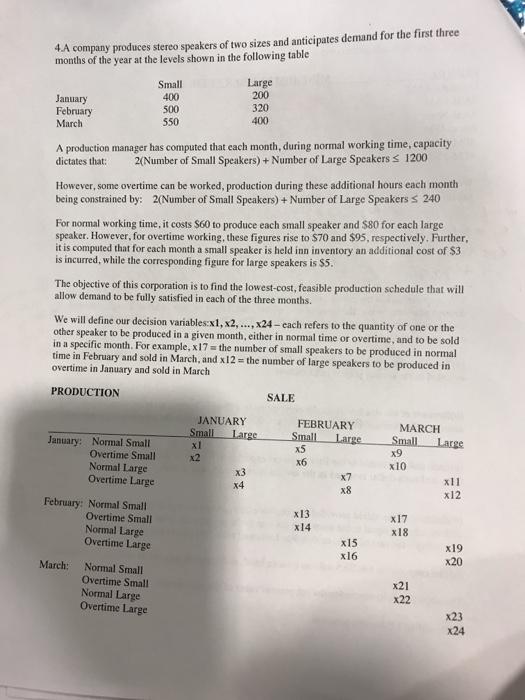

4.A company produces stereo speakers of two sizes and anticipates demand for the first three months of the year at the levels shown in

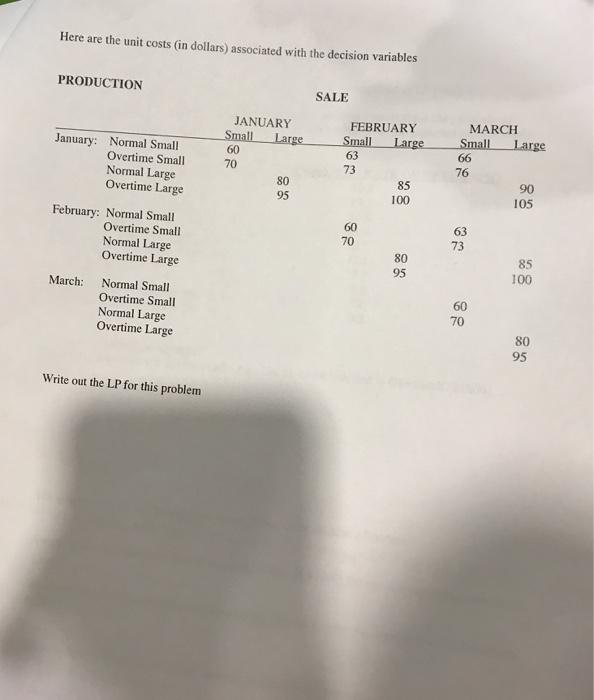

4.A company produces stereo speakers of two sizes and anticipates demand for the first three months of the year at the levels shown in the following table January February March A production manager has computed that each month, during normal working time, capacity 2(Number of Small Speakers) + Number of Large Speakers 1200 dictates that: Small 400 500 550 However, some overtime can be worked, production during these additional hours each month being constrained by: 2(Number of Small Speakers) + Number of Large Speakers 240 For normal working time, it costs $60 to produce each small speaker and $80 for each large speaker. However, for overtime working, these figures rise to $70 and $95, respectively. Further, it is computed that for each month a small speaker is held inn inventory an additional cost of $3 is incurred, while the corresponding figure for large speakers is $5. The objective of this corporation is to find the lowest-cost, feasible production schedule that will allow demand to be fully satisfied in each of the three months. January: Normal Small Overtime Small Normal Large Overtime Large February: Normal Small Overtime Small Normal Large Overtime Large Large 200 We will define our decision variables:x1, x2,...,x24-each refers to the quantity of one or the other speaker to be produced in a given month, either in normal time or overtime, and to be sold in a specific month. For example, x17 = the number of small speakers to be produced in normal time in February and sold in March, and x12= the number of large speakers to be produced in overtime in January and sold in March PRODUCTION March: 320 400 Normal Small Overtime Small Normal Large Overtime Large x4 JANUARY Small Large xl x2 SALE FEBRUARY Large Small x5 x6 x13 x14 x8 x15 x16 MARCH Small Large x9 x10 X17 x18 x21 x22 x11 x12 x19 x20 x23 x24 Here are the unit costs (in dollars) associated with the decision variables PRODUCTION January: Normal Small Overtime Small Normal Large Overtime Large February: Normal Small Overtime Small Normal Large Overtime Large March: Normal Small Overtime Small Normal Large Overtime Large Write out the LP for this problem JANUARY Small 60 70 Large 80 95 SALE FEBRUARY Small Large 63 73 60 70 85 100 80 95 MARCH Small Large 66 76 63 73 60 70 90 105 85 100 80 95

Step by Step Solution

★★★★★

3.40 Rating (150 Votes )

There are 3 Steps involved in it

Step: 1

To find the lowestcost feasible production schedule that satisfies the demand for each month we need to formulate a linear programming problem based on the given information Lets define the decision v...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started