Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A 21-tooth pinion rotating at 1500 rpm meshes with a 35-tooth gear in a spur gear reducer. Both pinion and gear are manufactured to

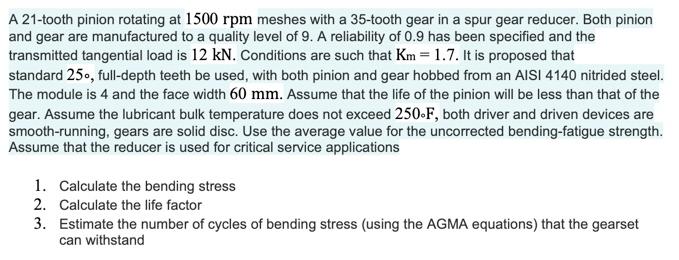

A 21-tooth pinion rotating at 1500 rpm meshes with a 35-tooth gear in a spur gear reducer. Both pinion and gear are manufactured to a quality level of 9. A reliability of 0.9 has been specified and the transmitted tangential load is 12 kN. Conditions are such that Km = 1.7. It is proposed that standard 25, full-depth teeth be used, with both pinion and gear hobbed from an AISI 4140 nitrided steel. The module is 4 and the face width 60 mm. Assume that the life of the pinion will be less than that of the gear. Assume the lubricant bulk temperature does not exceed 250-F, both driver and driven devices are smooth-running, gears are solid disc. Use the average value for the uncorrected bending-fatigue strength. Assume that the reducer is used for critical service applications 1. Calculate the bending stress 2. Calculate the life factor 3. Estimate the number of cycles of bending stress (using the AGMA equations) that the gearset can withstand

Step by Step Solution

There are 3 Steps involved in it

Step: 1

To solve this problem we need to calculate the bending stress life factor and estimate the number of ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started