Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A can with a hemispherical bottom is made by a hybrid process combining stretch-forming followed by deep drawing in the same punch stroke, starting

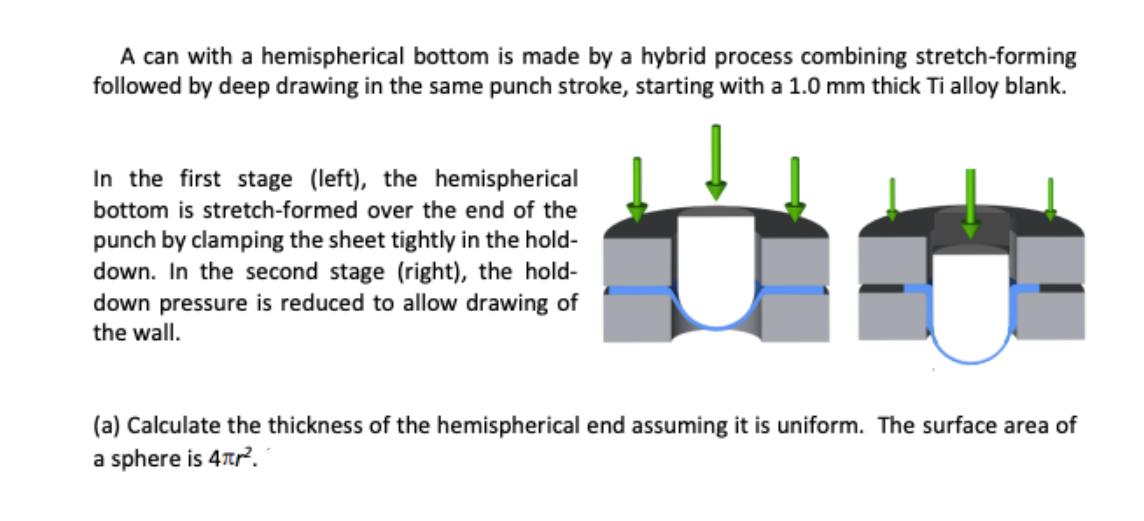

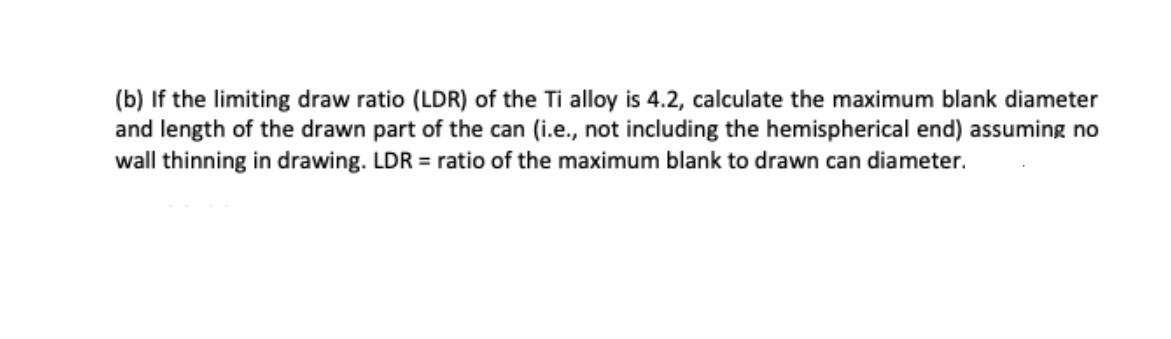

A can with a hemispherical bottom is made by a hybrid process combining stretch-forming followed by deep drawing in the same punch stroke, starting with a 1.0 mm thick Ti alloy blank. In the first stage (left), the hemispherical bottom is stretch-formed over the end of the punch by clamping the sheet tightly in the hold- down. In the second stage (right), the hold- down pressure is reduced to allow drawing of the wall. (a) Calculate the thickness of the hemispherical end assuming it is uniform. The surface area of a sphere is 4tr. (b) If the limiting draw ratio (LDR) of the Ti alloy is 4.2, calculate the maximum blank diameter and length of the drawn part of the can (i.e., not including the hemispherical end) assuming no wall thinning in drawing. LDR = ratio of the maximum blank to drawn can diameter. (c) Mark and clearly label on the yield surface below the state of stress during forming (assuming no work-hardening) in each of the areas i.-iii. (9) i. ii. iii. bottom of the hemispherical end during stretch-forming flange during drawing. wall during drawing. 02 &

Step by Step Solution

★★★★★

3.44 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

a Calculate the thickness of the hemispherical end assuming it is uniform The surface area of a sphere is 4r The thickness of the hemispherical end can be calculated by considering the volume of mater...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started