A company uses a variable speed honing machine to increase the smoothness of the inside walls of hydraulic jacks. The hone uses acid-dipped brushes

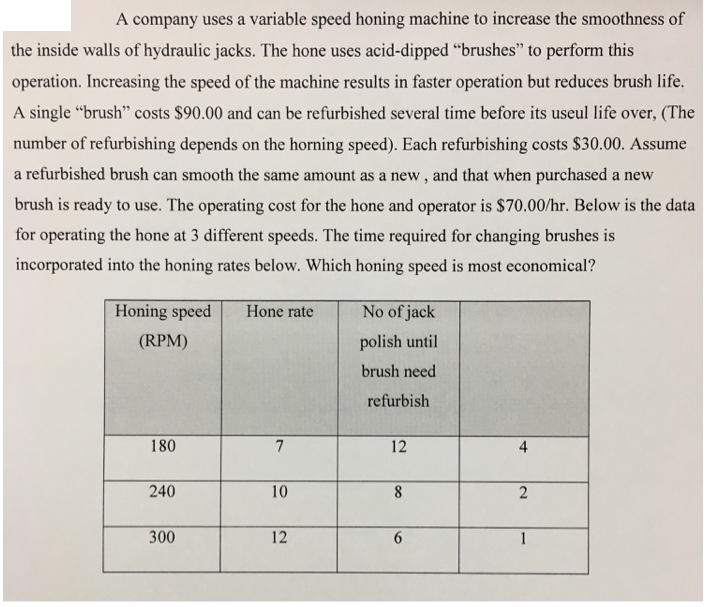

A company uses a variable speed honing machine to increase the smoothness of the inside walls of hydraulic jacks. The hone uses acid-dipped "brushes" to perform this operation. Increasing the speed of the machine results in faster operation but reduces brush life. A single "brush" costs $90.00 and can be refurbished several time before its useul life over, (The number of refurbishing depends on the horning speed). Each refurbishing costs $30.00. Assume a refurbished brush can smooth the same amount as a new, and that when purchased a new brush is ready to use. The operating cost for the hone and operator is $70.00/hr. Below is the data for operating the hone at 3 different speeds. The time required for changing brushes is incorporated into the honing rates below. Which honing speed is most economical? Honing speed (RPM) 180 240 300 Hone rate 7 10 12 No of jack polish until brush need refurbish 12 8 6 2 1

Step by Step Solution

3.33 Rating (156 Votes )

There are 3 Steps involved in it

Step: 1

To determine the most economical honing speed we need to calculate the total cost for each speed tak...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started