Question

A. Develop and solve a linear programming model to determine output and input requirements which will maximize profits. B. Senior management is considering implementing modifications

A. Develop and solve a linear programming model to determine output and input requirements which will maximize profits.

B. Senior management is considering implementing modifications to the Bayou 1 plant to increase output capacity. Due to budget constraints only one operation or process can be modified.

The cost of increasing capacity is approximately the same for each operation and would result an increase of capacity by 10%. Which operation (process) would you recommend to increase capacity. Support your answer with analysis.

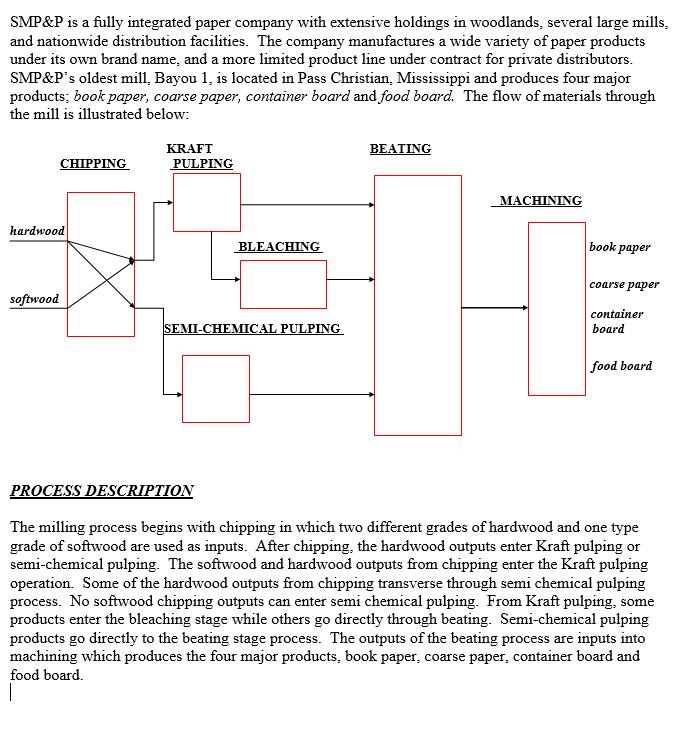

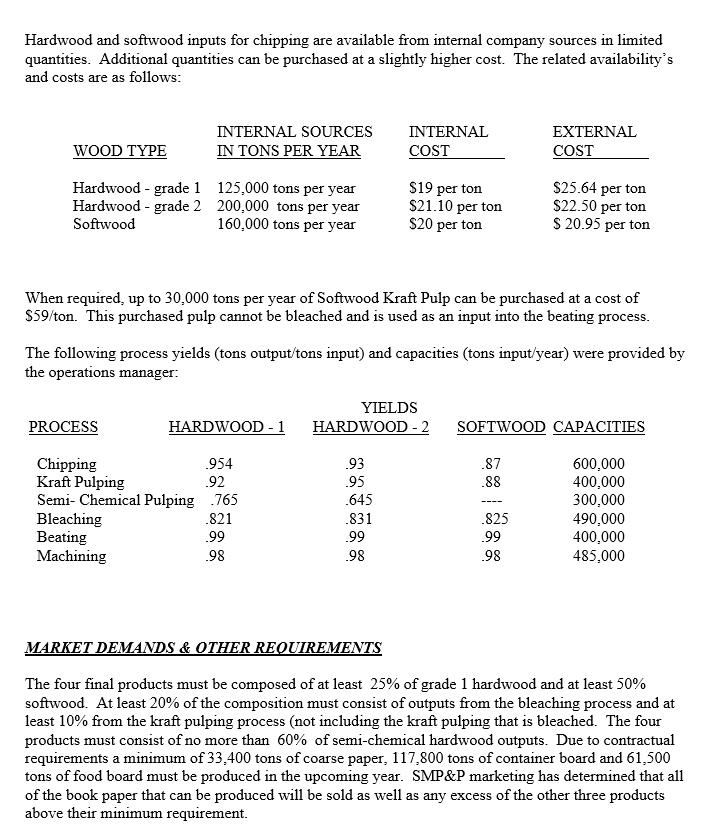

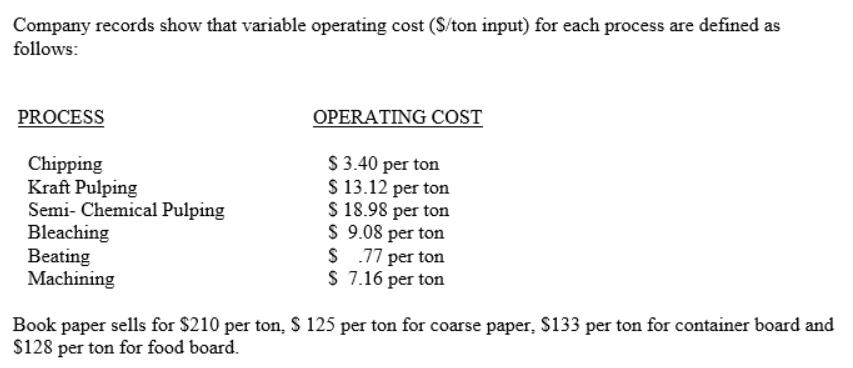

SMP&P is a fully integrated paper company with extensive holdings in woodlands, several large mills, and nationwide distribution facilities. The company manufactures a wide variety of paper products under its own brand name, and a more limited product line under contract for private distributors. SMP&P's oldest mill, Bayou 1, is located in Pass Christian, Mississippi and produces four major products; book paper, coarse paper, container board and food board. The flow of materials through the mill is illustrated below: KRAFT BEATING CHIPPING PULPING MACHINING hardwood BLEACHING book paper arse paper softwood container SEMI-CHEMICAL PULPING board food board PROCESS DESCRIPTION The milling process begins with chipping in which two different grades of hardwood and one type grade of softwood are used as inputs. After chipping, the hardwood outputs enter Kraft pulping or semi-chemical pulping. The softwood and hardwood outputs from chipping enter the Kraft pulping operation. Some of the hardwood outputs from chipping transverse through semi chemical pulping process. No softwood chipping outputs can enter semi chemical pulping. From Kraft pulping, some products enter the bleaching stage while others go directly through beating. Semi-chemical pulping products go directly to the beating stage process. The outputs of the beating process are inputs into machining which produces the four major products, book paper, coarse paper, container board and food board.

Step by Step Solution

3.48 Rating (161 Votes )

There are 3 Steps involved in it

Step: 1

ceSetwoodfor Beating BACKGROUND SMPP is a fully integrated paper company with extensive holdings in ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started