Answered step by step

Verified Expert Solution

Question

1 Approved Answer

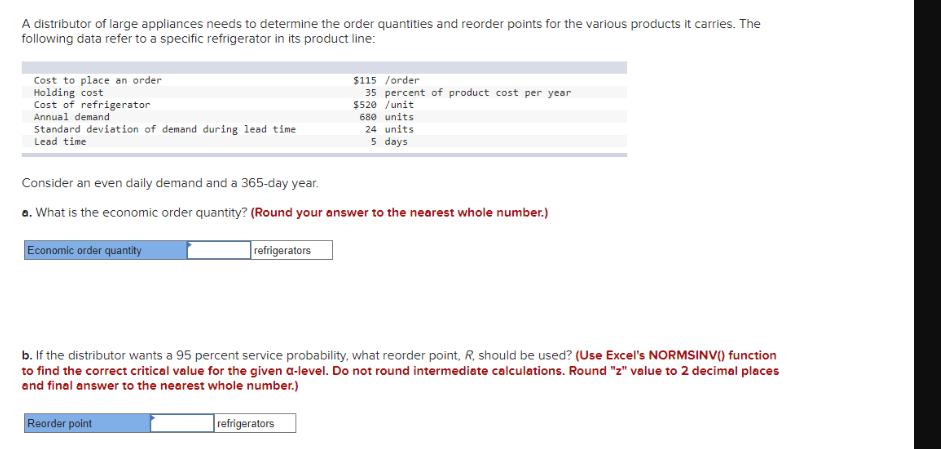

A distributor of large appliances needs to determine the order quantities and reorder points for the various products it carries. The following data refer

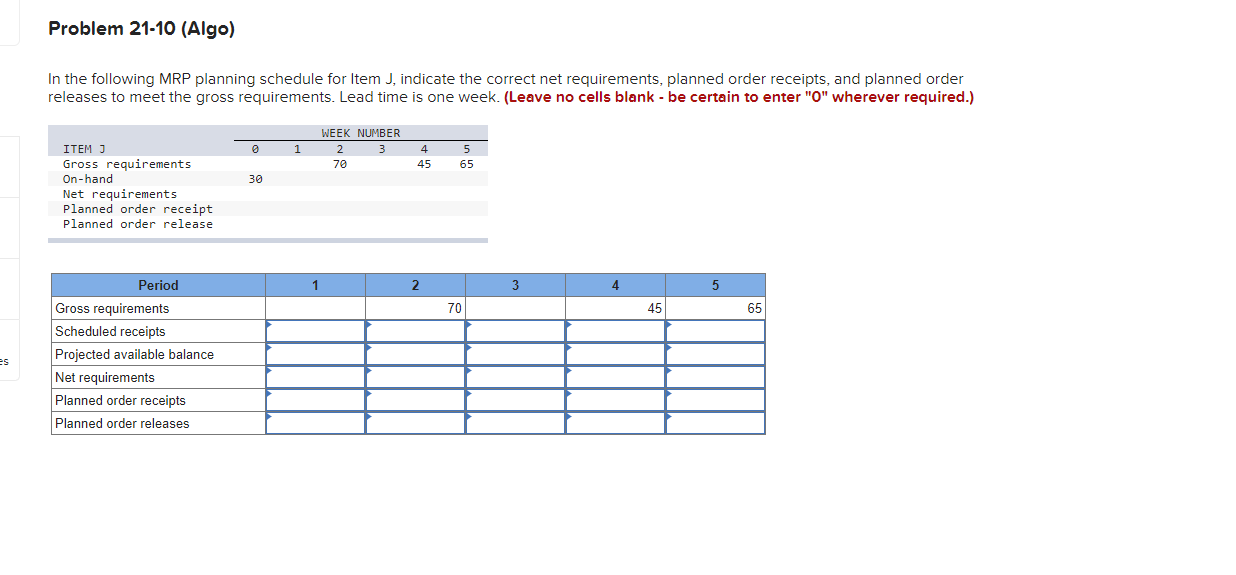

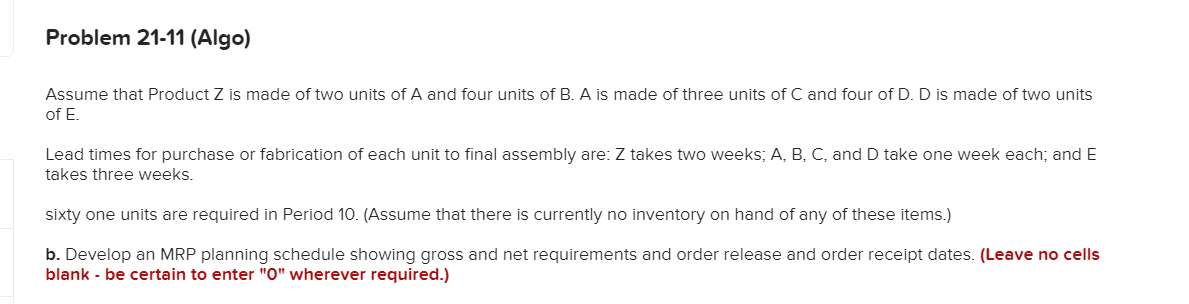

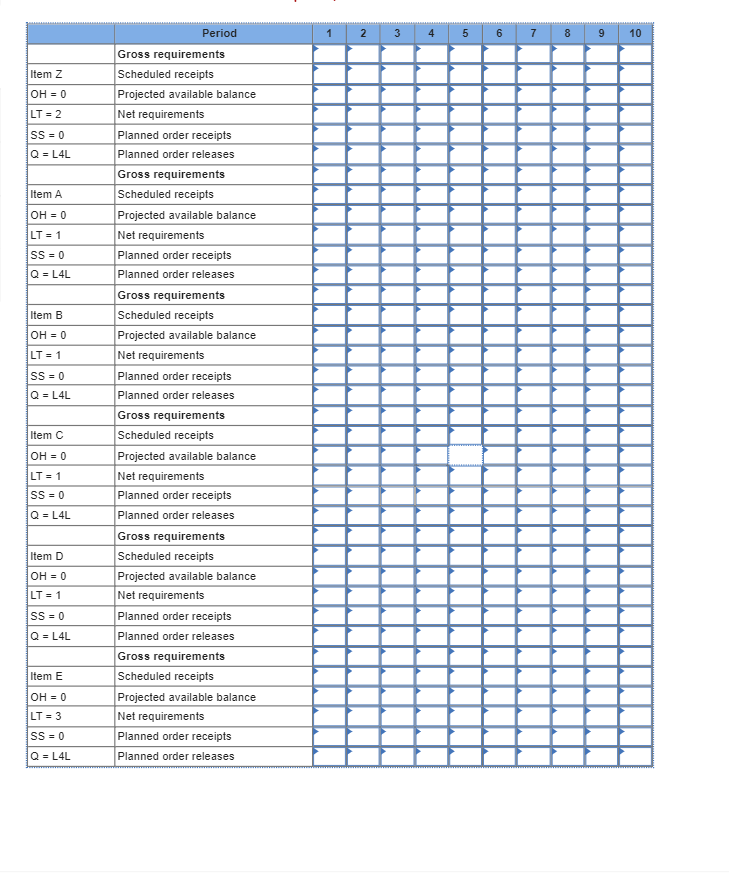

A distributor of large appliances needs to determine the order quantities and reorder points for the various products it carries. The following data refer to a specific refrigerator in its product line: Cost to place an order Holding cost Cost of refrigerator Annual demand Standard deviation of demand during lead time Lead time $115 /order 35 percent of product cost per year $520 /unit 680 units 24 units 5 days Consider an even daily demand and a 365-day year. a. What is the economic order quantity? (Round your answer to the nearest whole number.) Economic order quantity refrigerators b. If the distributor wants a 95 percent service probability, what reorder point, R, should be used? (Use Excel's NORMSINV() function to find the correct critical value for the given a-level. Do not round intermediate calculations. Round "z" value to 2 decimal places and final answer to the nearest whole number.) Reorder point refrigerators es Problem 21-10 (Algo) In the following MRP planning schedule for Item J, indicate the correct net requirements, planned order receipts, and planned order releases to meet the gross requirements. Lead time is one week. (Leave no cells blank - be certain to enter "O" wherever required.) ITEM J Gross requirements On-hand Net requirements Planned order receipt Planned order release Period Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases WEEK NUMBER 1 2 3 4 5 70 45 65 30 1 2 70 3 4 5 45 65 Problem 21-11 (Algo) Assume that Product Z is made of two units of A and four units of B. A is made of three units of C and four of D. D is made of two units of E. Lead times for purchase or fabrication of each unit to final assembly are: Z takes two weeks; A, B, C, and D take one week each; and E takes three weeks. sixty one units are required in Period 10. (Assume that there is currently no inventory on hand of any of these items.) b. Develop an MRP planning schedule showing gross and net requirements and order release and order receipt dates. (Leave no cells blank - be certain to enter "O" wherever required.) Period 1 2 3 4 5 6 7 8 9 10 Item Z OH = 0 LT = 2 SS=0 Q = L4L Item A OH=0 LT = 1 SS-0 Q = L4L Item B OH = 0 LT = 1 SS=0 Q = L4L Item C OH=0 LT=1 SS=0 Q = L4L Item D OH = 0 LT = 1 SS=0 Q = L4L Item E OH = 0 LT=3 SS=0 Q = L4L Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases Gross requirements Scheduled receipts Projected available balance Net requirements Planned order receipts Planned order releases

Step by Step Solution

★★★★★

3.46 Rating (149 Votes )

There are 3 Steps involved in it

Step: 1

To calculate the economic order quantity and reorder point we can use the following formulas 1 Econo...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started