Question: A factory has five departments: A, B, C, D and E. Six different products are routed for processing through these departments in the daily production

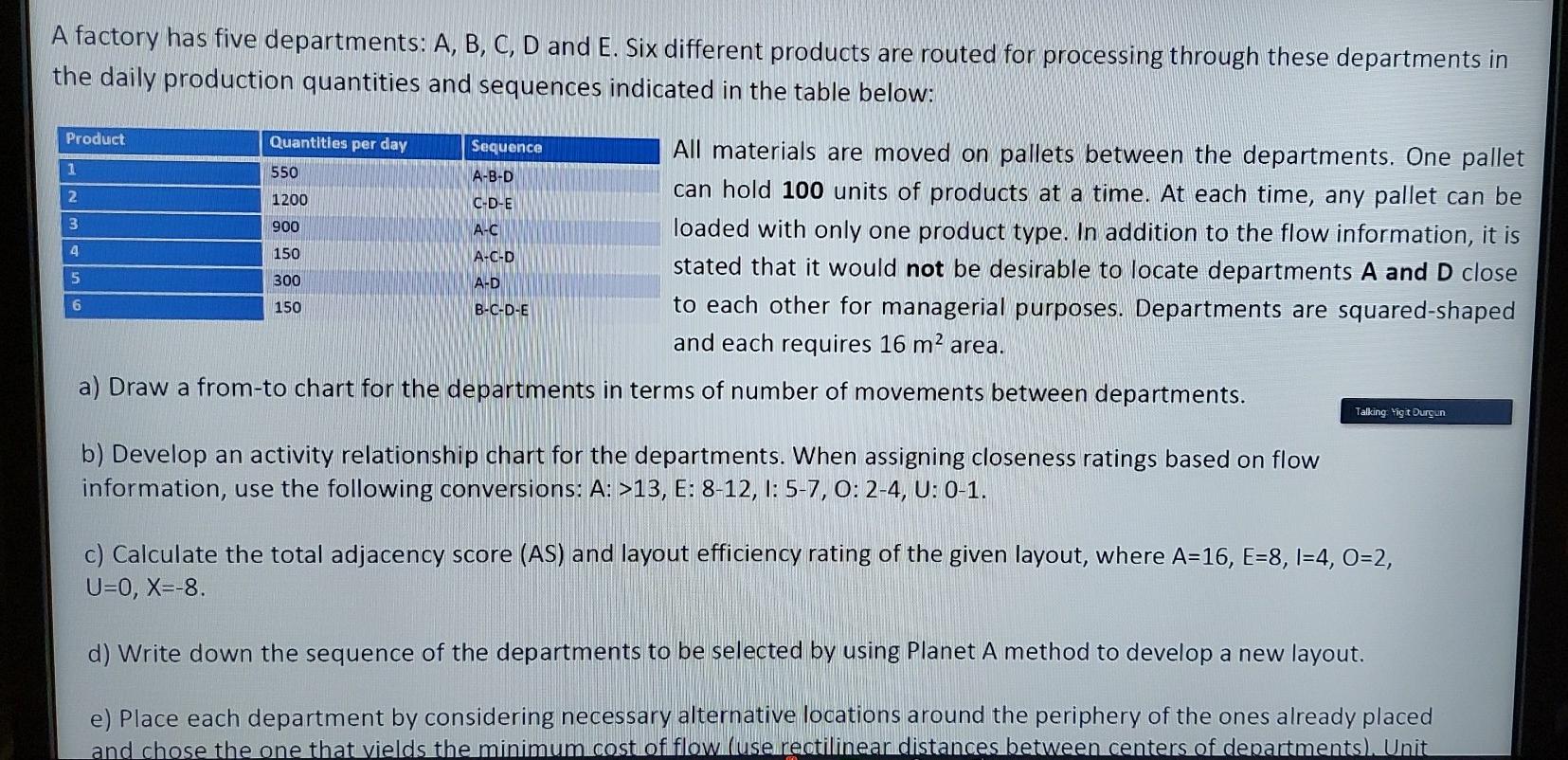

A factory has five departments: A, B, C, D and E. Six different products are routed for processing through these departments in the daily production quantities and sequences indicated in the table below: Product Sequence 1 550 A-B-D 2 1200 C-D-E 3 900 A-C 4 150 A-C-D Quantities per day All materials are moved on pallets between the departments. One pallet can hold 100 units of products at a time. At each time, any pallet can be loaded with only one product type. In addition to the flow information, it is stated that it would not be desirable to locate departments A and D close to each other for managerial purposes. Departments are squared-shaped and each requires 16 m2 area. a) Draw a from-to chart for the departments in terms of number of movements between departments. S 300 A-D 6 150 B-C-D-E Talking ligt Ourgun b) Develop an activity relationship chart for the departments. When assigning closeness ratings based on flow information, use the following conversions: A: >13, E: 8-12, 1: 5-7, 0:2-4, U: 0-1. c) Calculate the total adjacency score (AS) and layout efficiency rating of the given layout, where A=16, E=8, I=4, O=2, U=0, X=-8. d) Write down the sequence of the departments to be selected by using Planet A method to develop a new layout. e) Place each department by considering necessary alternative locations around the periphery of the ones already placed and chose the one that vields the minimum cost of flowiltuse rectilinear distances between centers of departments) Unit A factory has five departments: A, B, C, D and E. Six different products are routed for processing through these departments in the daily production quantities and sequences indicated in the table below: Product Sequence 1 550 A-B-D 2 1200 C-D-E 3 900 A-C 4 150 A-C-D Quantities per day All materials are moved on pallets between the departments. One pallet can hold 100 units of products at a time. At each time, any pallet can be loaded with only one product type. In addition to the flow information, it is stated that it would not be desirable to locate departments A and D close to each other for managerial purposes. Departments are squared-shaped and each requires 16 m2 area. a) Draw a from-to chart for the departments in terms of number of movements between departments. S 300 A-D 6 150 B-C-D-E Talking ligt Ourgun b) Develop an activity relationship chart for the departments. When assigning closeness ratings based on flow information, use the following conversions: A: >13, E: 8-12, 1: 5-7, 0:2-4, U: 0-1. c) Calculate the total adjacency score (AS) and layout efficiency rating of the given layout, where A=16, E=8, I=4, O=2, U=0, X=-8. d) Write down the sequence of the departments to be selected by using Planet A method to develop a new layout. e) Place each department by considering necessary alternative locations around the periphery of the ones already placed and chose the one that vields the minimum cost of flowiltuse rectilinear distances between centers of departments) Unit

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock