Answered step by step

Verified Expert Solution

Question

1 Approved Answer

a, List the actions that planners should consider this week to (1) release new orders, (2) expedite scheduled receipts, and (3) delay a scheduled receipts

a, List the actions that planners should consider this week to (1) release new orders, (2) expedite scheduled receipts, and (3) delay a scheduled receipts due date.

b, Identify the good and bad points of MRP implementation at Flashy Flashers. Conclude by making suggestions on ways to improve its re-source planning process.

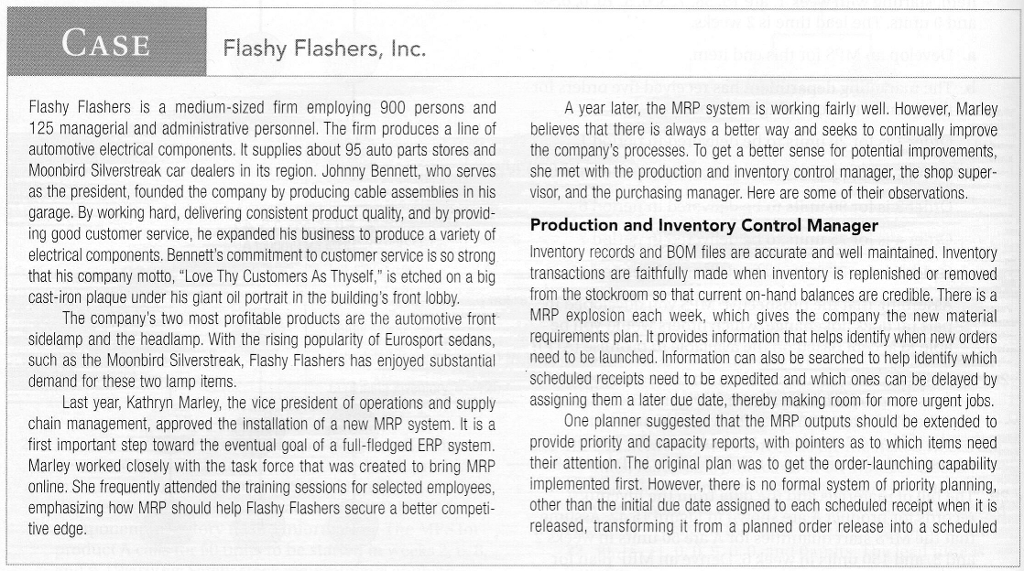

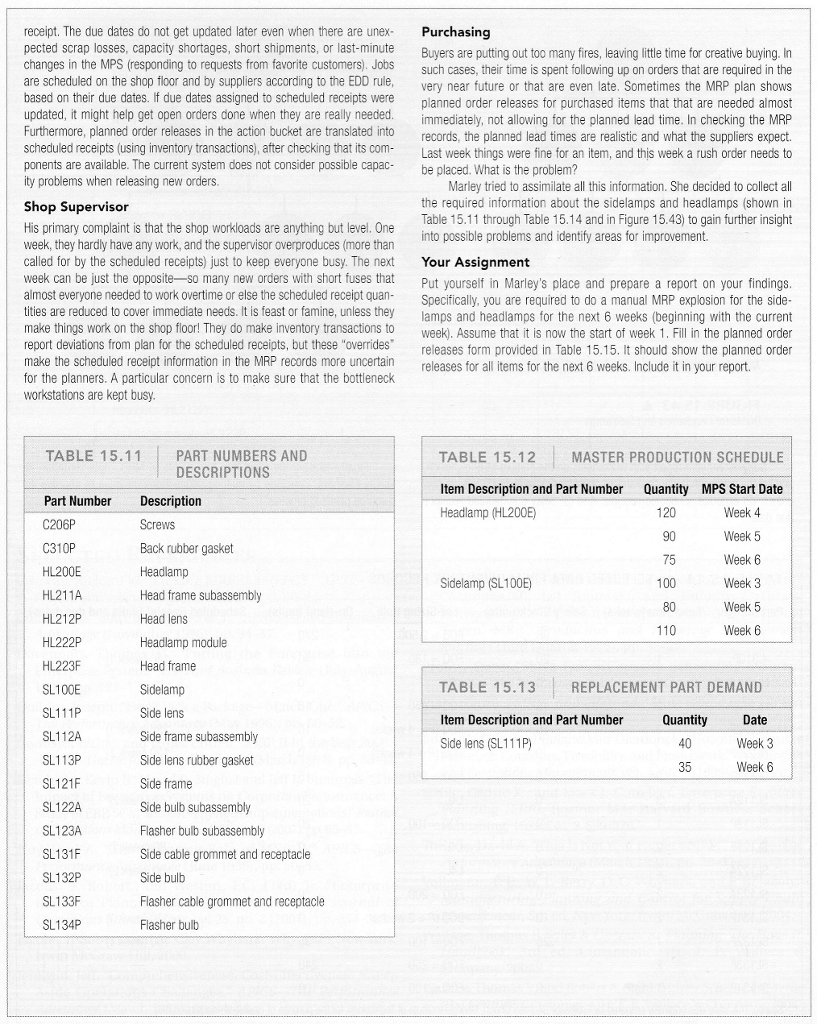

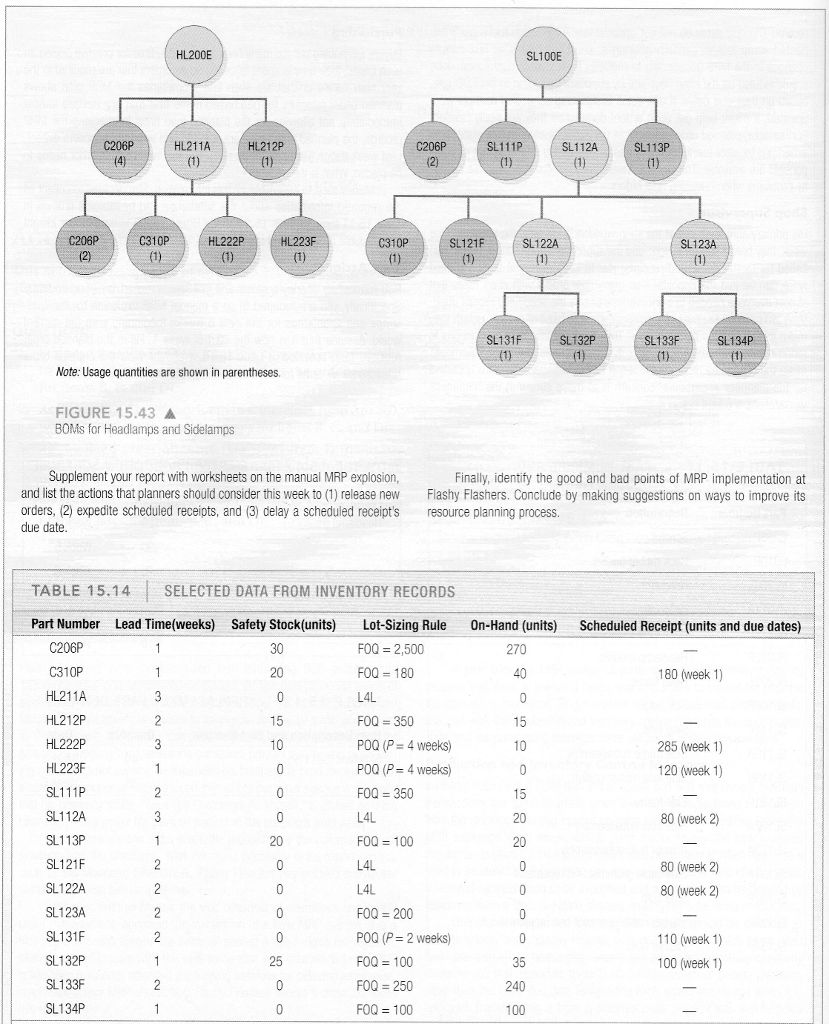

CASE Flashy Flashers, Inc. Flashy Flashers is a medium-sized firm employing 900 persons and 125 managerial and administrative personnel. The firm produces a line of automotive electrical components. It supplies about 95 auto parts stores and Moonbird Silverstreak car dealers in its region. Johnny Bennett, who serves as the president, founded the company by producing cable assemblies in his garage. By working hard, delivering consistent product quality, and by provid- ing good customer service, he expanded his business to produce a variety of electrical components. Bennett's commitment to customer service is so strong that his company motto, "Love Thy Customers As Thyself," is etched on a big cast-iron plaque under his giant oil portrait in the building's front lobby. The company's two most profitable products are the automotive front sidelamp and the headlamp. With the rising popularity of Eurosport sedans, such as the Moonbird Silverstreak, Flashy Flashers has enjoyed substantial demand for these two lamp items. Last year, Kathryn Marley, the vice president of operations and supply chain management, approved the installation of a new MRP system. It is a first important step toward the eventual goal of a full-fledged ERP system. Marley worked closely with the task force that was created to bring MRP online. She frequently attended the training sessions for selected employees, emphasizing how MRP should help Flashy Flashers secure a better competi- tive edge. A year later, the MRP system is working fairly well. However, Marley believes that there is always a better way and seeks to continually improve the company's processes. To get a better sense for potential improvements, she met with the production and inventory control manager, the shop super- visor, and the purchasing manager. Here are some of their observations Production and Inventory Control Manager Inventory records and BOM files are accurate and well maintained. Inventory transactions are faithfully made when inventory is replenished or removed from the stockroom so that current on-hand balances are credible. There is a MRP explosion each week, which gives the company the new material requirements plan. It provides information that helps identify when new orders need to be launched. Information can also be searched to help identify which scheduled receipts need to be expedited and which ones can be delayed by assigning them a later due date, thereby making room for more urgent jobs. One planner suggested that the MRP outputs should be extended to provide priority and capacity reports, with pointers as to which items need their attention. The original plan was to get the order-launching capability implemented first. However, there is no formal system of priority planning, other than the initial due date assigned to each scheduled receipt when it is released, transforming it from a planned order release into a scheduled receipt. The due dates do not get updated later even when there are unex- pected scrap losses, capacity shortages, short shipments, or last-minute changes in the MPS (responding to requests from favorite customers). Jobs are scheduled on the shop floor and by suppliers according to the EDD rule, based on their due dates. If due dates assigned to scheduled receipts were updated, it might help get open orders done when they are really needed. Furthermore, planned order releases in the action bucket are translated scheduled receipts (using inventory transactions), after checking that its com- ponents are available. The current system does not consider possible capac- ity problems when releasing new orders. Shop Supervisor His primary complaint is that the shop workloads are anything but level. One week, they hardly have any work, and the supervisor overproduces (more than called for by the scheduled receipts) just to keep everyone busy. The next week can be just the oppositeso many new orders with short fuses that almost everyone needed to work overtime or else the scheduled receipt quan tities are reduced to cover immediate needs. It is feast or famine, unless they make things work on the shop floor! They do make inventory transactions to report deviations from plan for the scheduled receipts, but these "overrides make the scheduled receipt information in the MRP records more uncertain for the planners. A particular concern is to make sure that the bottleneck workstations are kept busy. Purchasing Buyers are putting out too many fires, leaving little time for creative buying. In such cases, their time is spent following up on orders that are required in the very near future or that are even late. Sometimes the MRP plan shows planned order releases for purchased items that that are needed almost immediately, not allowing for the planned lead time. In checking the MRP records, the planned lead times are realistic and what the suppliers expect. Last week things were fine for an item, and this week a rush order needs to be placed. What is the problem? Marley tried to assimilate all this information. She decided to collect all the required information about the sidelamps and headlamps (shown in Table 15.11 through Table 15.14 and in Figure 15.43) to gain further insight into possible problems and identify areas for improvement. Your Assignment Put yourself in Marley's place and prepare a report on your findings Specifically, you are required to do a manual MRP explosion for the side- lamps and headlamps for the next 6 weeks (beginning with the current week). Assume that it is now the start of week 1. Fill in the planned order releases form provided in Table 15.15. It should show the planned order releases for all items for the next 6 weeks. Include it in your report TABLE 15.11 PART NUMBERS AND DESCRIPTIONS TABLE 15.12 MASTER PRODUCTION SCHEDULE Part Number Description Item Description and Part Number Headlamp (HL200E) Quantity MPS Start Date Week 4 Week 5 C206P C310P HL200E Week 6 Sidelamp (SL100E) Week 3 HL211A HL212P Week 5 Week 6 HL222P TABLE 15.13 REPLACEMENT PART DEMAND Screws Back rubber gasket Headlamp Head frame subassembly Head lens Headlamp module Head frame Sidelamp Side lens Side frame subassembly Side lens rubber gasket Side frame Side bulb subassembly Flasher bulb subassembly Side cable grommet and receptacle Side bulb Flasher cable grommet and receptacle Flasher bulb Date Item Description and Part Number Side lens (SL111P) HL223F SL100E SL111P SL112A SL113P SL121F SL122A SL123A SL131F SL132P SL133F SL134P Week 3 Week 6 HL200E SL100E C206P HL211A HL212P C206P (2) SL111P SL112A SL113P (0) C206P C310P HL222P H L223F (1) SL123A C310P (1) SL1217 (1) SL122A SL131F SL 132P SL133F SL134P Note:Usage quantities are shown in parentheses FIGURE 15.43 A BOMs for Headlamps and Sidelamps Supplement your report with worksheets on the manual MRP explosion, and list the actions that planners should consider this week to (1) release new orders, (2) expedite scheduled receipts, and (3) delay a scheduled receipt's due date. Finally, identify the good and bad points of MRP implementation at Flashy Flashers. Conclude by making suggestions on ways to improve its resource planning process. TABLE 15.14 SELECTED DATA FROM INVENTORY RECORDS Safety Stock(units) On-Hand (units) Scheduled Receipt (units and due dates) Part Number Lead Time(weeks) C206P C310P HL211A HL212P 180 (week 1) Lot-Sizing Rule FOQ = 2,500 FOQ = 180 L4L FOQ = 350 POQ (P = 4 weeks) POQ (P= 4 weeks) FOQ = 350 HL222P 285 (week 1) 120 (week 1) L4L 80 (week 2) FOQ = 100 L4L HL223F SL111P SL112A SL113P SL121F SL122A SL123A SL131F SL132P SL133F SL134P 80 (week 2) 80 (week 2) L4L FOQ = 200 POQ (P= 2 weeks) FOQ = 100 FOQ = 250 FOQ = 100 110 (week 1) 100 (week 1) CASE Flashy Flashers, Inc. Flashy Flashers is a medium-sized firm employing 900 persons and 125 managerial and administrative personnel. The firm produces a line of automotive electrical components. It supplies about 95 auto parts stores and Moonbird Silverstreak car dealers in its region. Johnny Bennett, who serves as the president, founded the company by producing cable assemblies in his garage. By working hard, delivering consistent product quality, and by provid- ing good customer service, he expanded his business to produce a variety of electrical components. Bennett's commitment to customer service is so strong that his company motto, "Love Thy Customers As Thyself," is etched on a big cast-iron plaque under his giant oil portrait in the building's front lobby. The company's two most profitable products are the automotive front sidelamp and the headlamp. With the rising popularity of Eurosport sedans, such as the Moonbird Silverstreak, Flashy Flashers has enjoyed substantial demand for these two lamp items. Last year, Kathryn Marley, the vice president of operations and supply chain management, approved the installation of a new MRP system. It is a first important step toward the eventual goal of a full-fledged ERP system. Marley worked closely with the task force that was created to bring MRP online. She frequently attended the training sessions for selected employees, emphasizing how MRP should help Flashy Flashers secure a better competi- tive edge. A year later, the MRP system is working fairly well. However, Marley believes that there is always a better way and seeks to continually improve the company's processes. To get a better sense for potential improvements, she met with the production and inventory control manager, the shop super- visor, and the purchasing manager. Here are some of their observations Production and Inventory Control Manager Inventory records and BOM files are accurate and well maintained. Inventory transactions are faithfully made when inventory is replenished or removed from the stockroom so that current on-hand balances are credible. There is a MRP explosion each week, which gives the company the new material requirements plan. It provides information that helps identify when new orders need to be launched. Information can also be searched to help identify which scheduled receipts need to be expedited and which ones can be delayed by assigning them a later due date, thereby making room for more urgent jobs. One planner suggested that the MRP outputs should be extended to provide priority and capacity reports, with pointers as to which items need their attention. The original plan was to get the order-launching capability implemented first. However, there is no formal system of priority planning, other than the initial due date assigned to each scheduled receipt when it is released, transforming it from a planned order release into a scheduled receipt. The due dates do not get updated later even when there are unex- pected scrap losses, capacity shortages, short shipments, or last-minute changes in the MPS (responding to requests from favorite customers). Jobs are scheduled on the shop floor and by suppliers according to the EDD rule, based on their due dates. If due dates assigned to scheduled receipts were updated, it might help get open orders done when they are really needed. Furthermore, planned order releases in the action bucket are translated scheduled receipts (using inventory transactions), after checking that its com- ponents are available. The current system does not consider possible capac- ity problems when releasing new orders. Shop Supervisor His primary complaint is that the shop workloads are anything but level. One week, they hardly have any work, and the supervisor overproduces (more than called for by the scheduled receipts) just to keep everyone busy. The next week can be just the oppositeso many new orders with short fuses that almost everyone needed to work overtime or else the scheduled receipt quan tities are reduced to cover immediate needs. It is feast or famine, unless they make things work on the shop floor! They do make inventory transactions to report deviations from plan for the scheduled receipts, but these "overrides make the scheduled receipt information in the MRP records more uncertain for the planners. A particular concern is to make sure that the bottleneck workstations are kept busy. Purchasing Buyers are putting out too many fires, leaving little time for creative buying. In such cases, their time is spent following up on orders that are required in the very near future or that are even late. Sometimes the MRP plan shows planned order releases for purchased items that that are needed almost immediately, not allowing for the planned lead time. In checking the MRP records, the planned lead times are realistic and what the suppliers expect. Last week things were fine for an item, and this week a rush order needs to be placed. What is the problem? Marley tried to assimilate all this information. She decided to collect all the required information about the sidelamps and headlamps (shown in Table 15.11 through Table 15.14 and in Figure 15.43) to gain further insight into possible problems and identify areas for improvement. Your Assignment Put yourself in Marley's place and prepare a report on your findings Specifically, you are required to do a manual MRP explosion for the side- lamps and headlamps for the next 6 weeks (beginning with the current week). Assume that it is now the start of week 1. Fill in the planned order releases form provided in Table 15.15. It should show the planned order releases for all items for the next 6 weeks. Include it in your report TABLE 15.11 PART NUMBERS AND DESCRIPTIONS TABLE 15.12 MASTER PRODUCTION SCHEDULE Part Number Description Item Description and Part Number Headlamp (HL200E) Quantity MPS Start Date Week 4 Week 5 C206P C310P HL200E Week 6 Sidelamp (SL100E) Week 3 HL211A HL212P Week 5 Week 6 HL222P TABLE 15.13 REPLACEMENT PART DEMAND Screws Back rubber gasket Headlamp Head frame subassembly Head lens Headlamp module Head frame Sidelamp Side lens Side frame subassembly Side lens rubber gasket Side frame Side bulb subassembly Flasher bulb subassembly Side cable grommet and receptacle Side bulb Flasher cable grommet and receptacle Flasher bulb Date Item Description and Part Number Side lens (SL111P) HL223F SL100E SL111P SL112A SL113P SL121F SL122A SL123A SL131F SL132P SL133F SL134P Week 3 Week 6 HL200E SL100E C206P HL211A HL212P C206P (2) SL111P SL112A SL113P (0) C206P C310P HL222P H L223F (1) SL123A C310P (1) SL1217 (1) SL122A SL131F SL 132P SL133F SL134P Note:Usage quantities are shown in parentheses FIGURE 15.43 A BOMs for Headlamps and Sidelamps Supplement your report with worksheets on the manual MRP explosion, and list the actions that planners should consider this week to (1) release new orders, (2) expedite scheduled receipts, and (3) delay a scheduled receipt's due date. Finally, identify the good and bad points of MRP implementation at Flashy Flashers. Conclude by making suggestions on ways to improve its resource planning process. TABLE 15.14 SELECTED DATA FROM INVENTORY RECORDS Safety Stock(units) On-Hand (units) Scheduled Receipt (units and due dates) Part Number Lead Time(weeks) C206P C310P HL211A HL212P 180 (week 1) Lot-Sizing Rule FOQ = 2,500 FOQ = 180 L4L FOQ = 350 POQ (P = 4 weeks) POQ (P= 4 weeks) FOQ = 350 HL222P 285 (week 1) 120 (week 1) L4L 80 (week 2) FOQ = 100 L4L HL223F SL111P SL112A SL113P SL121F SL122A SL123A SL131F SL132P SL133F SL134P 80 (week 2) 80 (week 2) L4L FOQ = 200 POQ (P= 2 weeks) FOQ = 100 FOQ = 250 FOQ = 100 110 (week 1) 100 (week 1)Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started