Question

A local manufacturing company produces heating and colling appliances for home and industrial applications. These include refrigerators, water coolers, water heaters, air conditioners, sandwich panels,

A local manufacturing company produces heating and colling appliances for home and industrial applications. These include refrigerators, water coolers, water heaters, air conditioners, sandwich panels, related spare parts and others. We focus here on the water heater production line, which is a batch production system manufacturing various heater capacities, ranging from 10 to 100 liters. Based on the 2017 and 2018 data the line produced around 120,000 heaters a year. As provided by the management, the average daily production has been about 425 units a day on average.

The maximum capacity of the line is 500 units per day also as indicated by the management. The line operates one or two shifts a day depending on the demand and workload. Commonly it operates for one shift a day. A shift is 8 hours with one-hour break in the middle. Setup of equipment is conducted within 30 minutes before the beginning of the shift for all equipment, including providing the needed tools and materials (this can be considered a form of capacity buffer concept). They do not have setups during the shift. A periodic preventive maintenance plan is in effect for the line. At the end of each month any necessary replacements or maintenance needs; according to the plan, is performed. This may take 45 min to one hour for all equipment. There is a maintenance team of 5 people; one of them is a mechanical engineer and the others are trained assistants. They perform all needed repairs as they occur; usually 30 min to one hour; without interrupting the work progress.

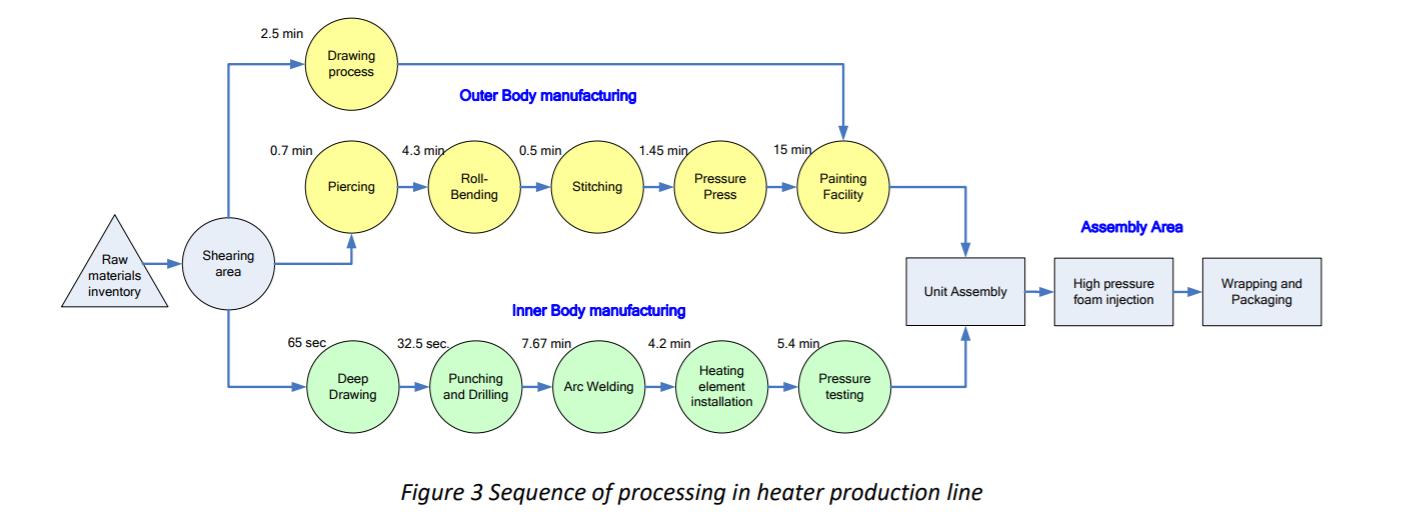

All models of the heaters are produced by almost the same processing steps. The processes are organized in seven work areas in the plant, as depicted in the flow diagram in Figure 3. This does not mean there are seven steps of processing. It is just how equipment are laid out in the plant. The details of the processing steps are given later. The processes used in manufacturing the heaters include shearing, rolling, piercing, welding, powder painting, foam injection, and the assembly of the other elements to the body of the heater, in addition to the testing and inspection. The flow diagram in Figure 3 showing the technologic order of the processing steps. You should observe that some operations are performed in parallel.

Production steps described:

Following the diagram in Figure 3, the production of the water heater proceeds as follow:

1. To produce the water heaters, the metal sheets needed are brought from the raw materials inventory to the shearing workstation. All needed parts for the inner and the outer subassemblies, are cut here to the required dimensions. Four workers work on the shearing workstation, and there are two similar shearing machines. Usually, they are dedicated; one machine for each type of parts. The process time for cutting the inner parts is 45 seconds and for the outer parts is 35 seconds on average.

2. For the inner parts of the heater, the deep drawing is used to form it, with an average processing time of 65 seconds. The flat metal sheet goes into the machine and comes out shaped like a long bowl.

3. This piece is then taken to the punching machine to make necessary details on the bowl. This process is fast which takes around 2.5 seconds on average. Yet trimming and edge preparation are also made here, for additional time of 30 seconds.

4. Parts are transported to the welding station, which takes about 7.67 minutes per units. There are seven welding units available in this station.

5. The heating element is then added by workers. Installing the heating elements takes 4.2 minutes and there are five parallel work areas in this station run by highly skilled technicians. 6. After that the entire inner subassembly is considered complete and is taken to the high-pressure testing station, to be tested under water for any gaps or leakage. If there is any leakage, the machine takes the part out of the water and a worker welds the areas that need coverage. There are five parallel testers, and the process time is 5.4 minutes on average. The subassembly is now ready for assembling.

7. Now for producing the outer subassembly, the cut-out sheets of metal are also divided; where the small pieces are taken to one of three drawing machines that can turn them into lids with a process time of 2.50 minutes including the transportation.

8. The larger cut-out sheets are taken to the piercing machine to prepare for the installation of the thermostat. The process time is an average of 0.7 minutes.

9. From the piercing process, parts are taken to roll-bending station to form the metal sheet in the cylindrical shape of the heater. The process time is 4.3 minutes. There are six parallel roll-bending machines; each is run by two operators.

10. The outer body cylinders are taken to a “stitching machine” to roll-over the cylinder edges by a seaming process, which takes average of 0.5 minutes.

11. Cylinders are then taken to a press machine to secure that it is well stitched, with process time of 1.45 minutes. There are three presses available.

12. Paint spraying: both the cylinders and the lids are taken to a painting station. They are cleaned, powderpainted and heated. This takes 15 minutes on average. The painting facility can accommodate 30 units for spraying simultaneously.

13. At this point, all heater is ready for assembly. The heater subassemblies and components are assembled with inner and outer bodies, thermostat, on/off switch, supply and drainpipes, etc. There are 24 workers performing this assembly process in the assembly area. They work in groups of two workers and on average they can finish a complete heater in 10 minutes.

14. The complete heater is taken to the foaming station to inject foam inside the heater between the inner subassembly and the outer body. This ensures better heating efficiency. it takes around 4.75 minutes. The high-pressure foam injection system can serve 5 foam injectors in parallel.

15. Finally, the product is conveyed to plastic wrapping and packaging. There are two packing units operated by 6 workers. One heater takes an average of 2 minutes to be finished.

THE QUESTION:

1. Believing that there is always a room for improvement, you are required to evaluate the production line and assess its potential. Use the knowledge gained in our course in order to provide an assessment of the line performance. You are required to verify the production and capacity data given by the management, at the introduction section. The available information showed that the line produced 425 units daily on average during the years 2017 and 2018. It was also mentioned that the line has the capability to reach 500 units per day. Assuming the line settings are still the same as in 2017-2018, you need to verify that information. Show all necessary calculations and explain yourself thoroughly.

2. If the management allows materials for 450 units per day, with the data given in the line description, is the line doing well assuming practical worst case performance? Show all of your calculations and explain them thoroughly. You make justified assumption in your work, yet you must explain them adequately.

Raw materials inventory Shearing area 2.5 min 0.7 min Drawing process 65 sec Piercing Deep Drawing 4.3 min 32.5 sec Outer Body manufacturing Roll- Bending Punching and Drilling 0.5 min H Stitching 1.45 miny Inner Body manufacturing 7.67 min Arc Welding 4.2 min Pressure Press Heating element installation 15 min Painting Facility 5.4 min Pressure testing Unit Assembly Figure 3 Sequence of processing in heater production line Assembly Area High pressure foam injection Wrapping and Packaging

Step by Step Solution

3.41 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

Personally I feel that sustainable continuous improvement CI requires the following thinking and act...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started