A manual assembly line is being planned to produce a small consumer appliance. The work elements, element times, and precedence constraints are indicated in

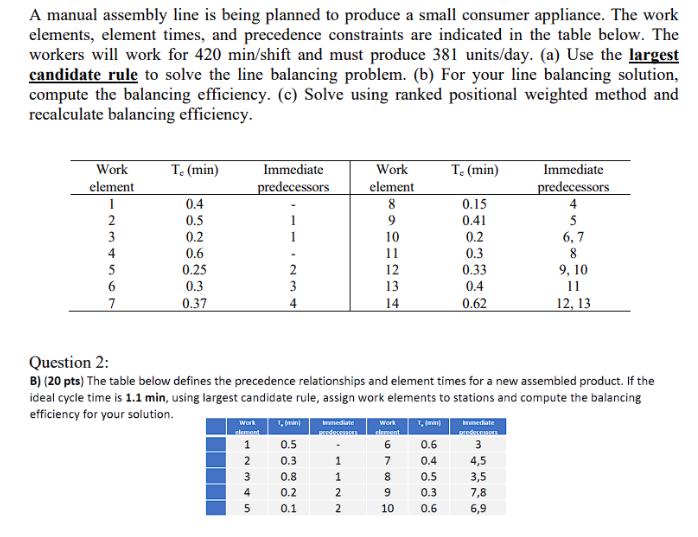

A manual assembly line is being planned to produce a small consumer appliance. The work elements, element times, and precedence constraints are indicated in the table below. The workers will work for 420 min/shift and must produce 381 units/day. (a) Use the largest candidate rule to solve the line balancing problem. (b) For your line balancing solution, compute the balancing efficiency. (c) Solve using ranked positional weighted method and recalculate balancing efficiency. Work element 1 2 3 4 5 6 7 Te (min) 0.4 0.5 0.2 0.6 0.25 0.3 0.37 Immediate predecessors Work slement 12345 AWN 3 4 Question 2: B) (20 pts) The table below defines the precedence relationships and element times for a new assembled product. If the ideal cycle time is 1.1 min, using largest candidate rule, assign work elements to stations and compute the balancing efficiency for your solution. 1. pin 0.5 0.3 0.8 0.2 5 0.1 Immediate wwwdecem 1 Work element 8 9 10 11 12 13 14 1 2 2 Work element 6 7699 8 10 1. min) daged T. (min) 0.15 0.41 0.2 0.3 0.33 0.4 0.62 0.6 0.4 0.5 0.3 0.6 bediate Indecours 3 4,5 3,5 7,8 6,9 Immediate predecessors 4 5 6,7 8 9, 10 11 12, 13 ww.

Step by Step Solution

3.44 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Answer a To solve the line balancing problem using the largest candidate rule we need to assign work elements to stations in a way that maximizes the efficiency of the assembly line The largest candid...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started