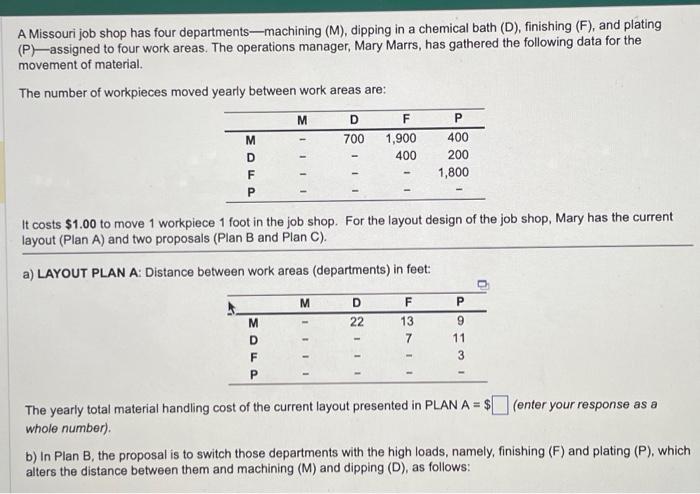

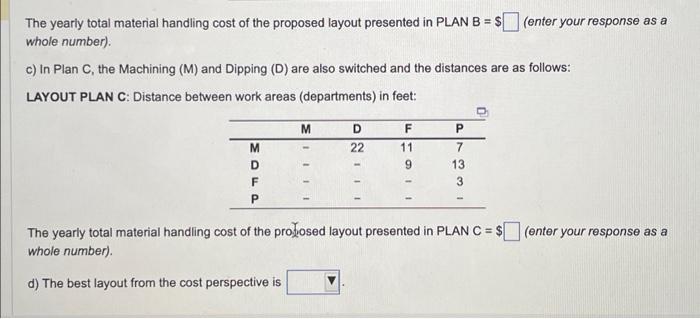

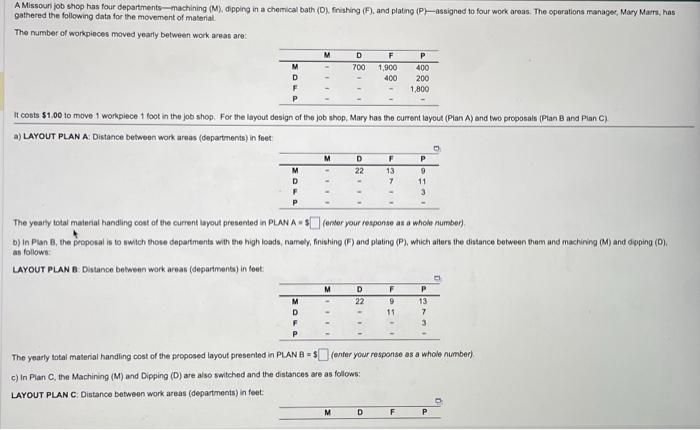

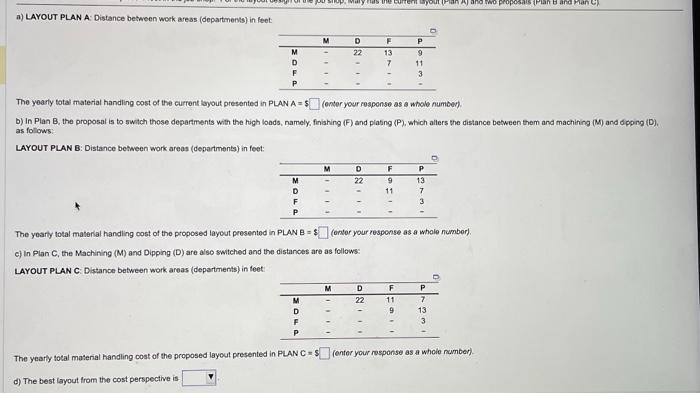

A Missouri job shop has four departments - machining (M), dipping in a chemical bath (D), finishing (F), and plating (P)-assigned to four work areas. The operations manager, Mary Marrs, has gathered the following data for the movement of material. The number of workpieces moved yearly between work areas are: It costs $1.00 to move 1 workpiece 1 foot in the job shop. For the layout design of the job shop, Mary has the current layout (Plan A) and two proposals (Plan B and Plan C). a) LAYOUT PLAN A: Distance between work areas (departments) in feet: The yearly total material handling cost of the current layout presented in PLAN A =$ (enter your response as a whole number). b) In Plan B, the proposal is to switch those departments with the high loads, namely, finishing (F) and plating (P), which alters the distance between them and machining (M) and dipping (D), as follows: The yearly total material handling cost of the proposed layout presented in PLAN B =$ (enter your response as a whole number). c) In Plan C, the Machining (M) and Dipping (D) are also switched and the distances are as follows: LAYOUT PLAN C: Distance between work areas (departments) in feet: The yearly total material handling cost of the projosed layout presented in PLAN C =$ (enter your response as a whole number). d) The best layout from the cost perspective is A Missoun job shop has four departments-machining (M), dipping in a chemical bath (D), frishing ( F ), and plating (P)-assigned to four work areas. The operations managec, Mary Marr, has gathered the following data for the movement of maserial. The number of workpioces moved yearly between work areas are: If costs $1.00 to move 1 workpiece 1 foot in the job shop. For the layout design of the job uhop, Mary has the current layout (Plan A) and two proposals (Plan B and Plan C) a) LAYOUT PLAN A: Distance between work areas (departments) in feet: The yearly total maleral handling coat of the current layout presemted in PLAN A = 1 (enter your response as a whole number). b) In Plan B, the Proposal is to nwith those departments with the high loads, namely, finishing (F) and plating (P), which alters the diatance between them and machining (M) and doping ( D ), as follow: LAYOUT PLAN B. Distance between work areas (departments) in teet The yearly tatai materiat handing cost of the proposed layout preseriled in PLAN B =$ (enter your response as a whole number) c) In Plan C, the Machining (M) and Dipping (D) are also switched and the distances are as follows: a) LAYOUT PLAN A: Distance between woek aress (departments) in feet: The yearly total material handling cost of the current tayout presented in PLAN A=$ (enter your rosponse as a whole number). b) In Plan B, the proposal is to switch those departments with the high loads, namely, finishing (F) and plating (P), which alters the distance between them and machining (M) and dipping (D), as follows: LAYOUT PLAN B: Distance between work areas (departments) in feet: The yearly total material handling cost of the proposed layout presented in PLAN B=$ (entor your response as a whole number). c) In Plan C, the Machining (M) and Dipping (D) are also switched and the distances are as follows: LAYOUT PLAN C: Distance between work areas (departments) in feet: The yearly total material handling cost of the proposed layout presented in PLAN C =$ (enter your rosponse as a whole number). d) The best layout from the cost perspective is