Question

a) Mr. Todd is concerned because the accou ntant may have ignored inflation in his analysis. While the first year costs are correct, Mr. Todd

a) Mr. Todd is concerned because the accou

ntant may have ignored inflation in his analysis. While the first year costs are correct, Mr. Todd believes the accountant has simply forgotten about the effects of inflation on the project cash flows after the first year. Mr. Todd’s expectation is that total labor costs including benefits will increase annually at the rate of inflation of 3 percent per year, starting in the fourth year of the project (with no inflation effect in years 1-3). Mr. Todd expects that raw material costs will increase with inflation (at 3%) in every year of the project. He also expects the unit cost of purchased pipe (at 45 cents in the first year) to increase annually at the rate of inflation during the life of the project. And inflation will not affect any other items. Now what is the project NPV? Now what do you recommend?

b)How would you account for the “lost sales” argument made by the sales personnel?

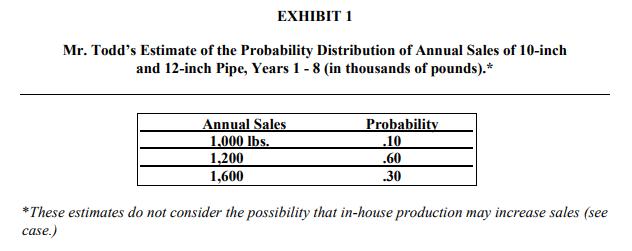

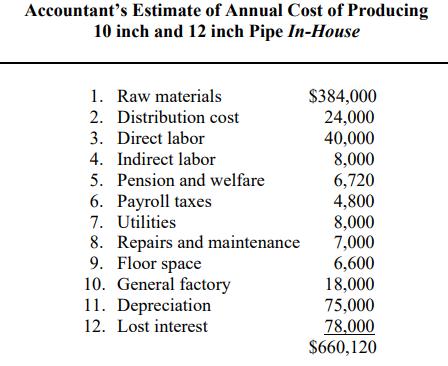

"If we do decide to produce the 10- and 12-inch pipe internally, it could solve our overstaffing problem," Mr. Ronie Todd, owner of Sharon Pipe, Inc. (SPI), remarked to Mr. Bill Long, the plant manager. "I'm reluctant to lay off anyone or even cut back hours. It's not good business and it's not the right thing to do if it can be at all avoided." The vast majority of SPI's sales come from drainage pipe, which is mainly used in various types of sewer systems. The pipe comes in a variety of sizes, and sales depend in part on customers perceiving the company as a "full-line producer." That is, a sales person is more likely to win an account if a distributor knows that a producer can promptly deliver various sizes of pipe. Typically this means that a manufacturer can quickly meet orders for the most commonly used sizes of pipe. These include pipe with diameters of 3 inches, 6 inches, and 8 inches. Occasionally, however, a distributor also needs 10-inch and 12-inch pipe. SPI has never produced these sizes internally because management believes that annual sales volume is too low to justify the start-up cost. If a distributor does request such pipe, SPI buys the pipe from a competitor who does manufacture the requested sizes. Mr. Todd has never carefully analyzed whether this is a good policy, and he thinks now is the time to do so, especially given the firm's staffing situation. As Mr. Todd thinks about it, there are two key benefits of producing the 10-inch and 12-inch pipe internally. First, SPI will avoid the cost of buying the pipe from a competitor. SPI pays 45 cents per pound for this pipe plus another 2 cents per pound in distribution costs to deliver the pipe to customers. Unit selling price is 56 cents per pound. Second, SPI's staffing problems would be helped. Though dollar sales have increased slightly in the last two years, Mr. Todd recognizes that the company is overstaffed by two employees. Sales simply aren't sufficient to keep all the production employees working full time. Mr. Todd thinks this could continue, given the state of the economy. In its 10-year history, SPI has never cut any worker's hours and has never laid off any employee. Mr. Todd is firmly committed to not doing so now. Mr. Todd can't be certain, of course, what sales of the 10-inch and 12-inch pipe will be in the future. He finds it helpful to think in terms of possible outcomes. He has set forth estimates along these lines in Exhibit 1. In addition, some sales people have complained that accounts have been lost when distributors realize that SPI does not produce 10-inch and 12-inch pipe internally. These distributors are worried that SPI will not be able to fill orders quickly. As a result, these sales people argue, the entire account, including 3-inch, 6-inch and 8-inch pipe, has been lost, not just the orders for 10- inch and 12-inch pipe.

Step by Step Solution

3.42 Rating (155 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started