Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A North Carolina furniture company would like to produce and sell outdoor patio furniture. They have identified four new models to build and showcase this

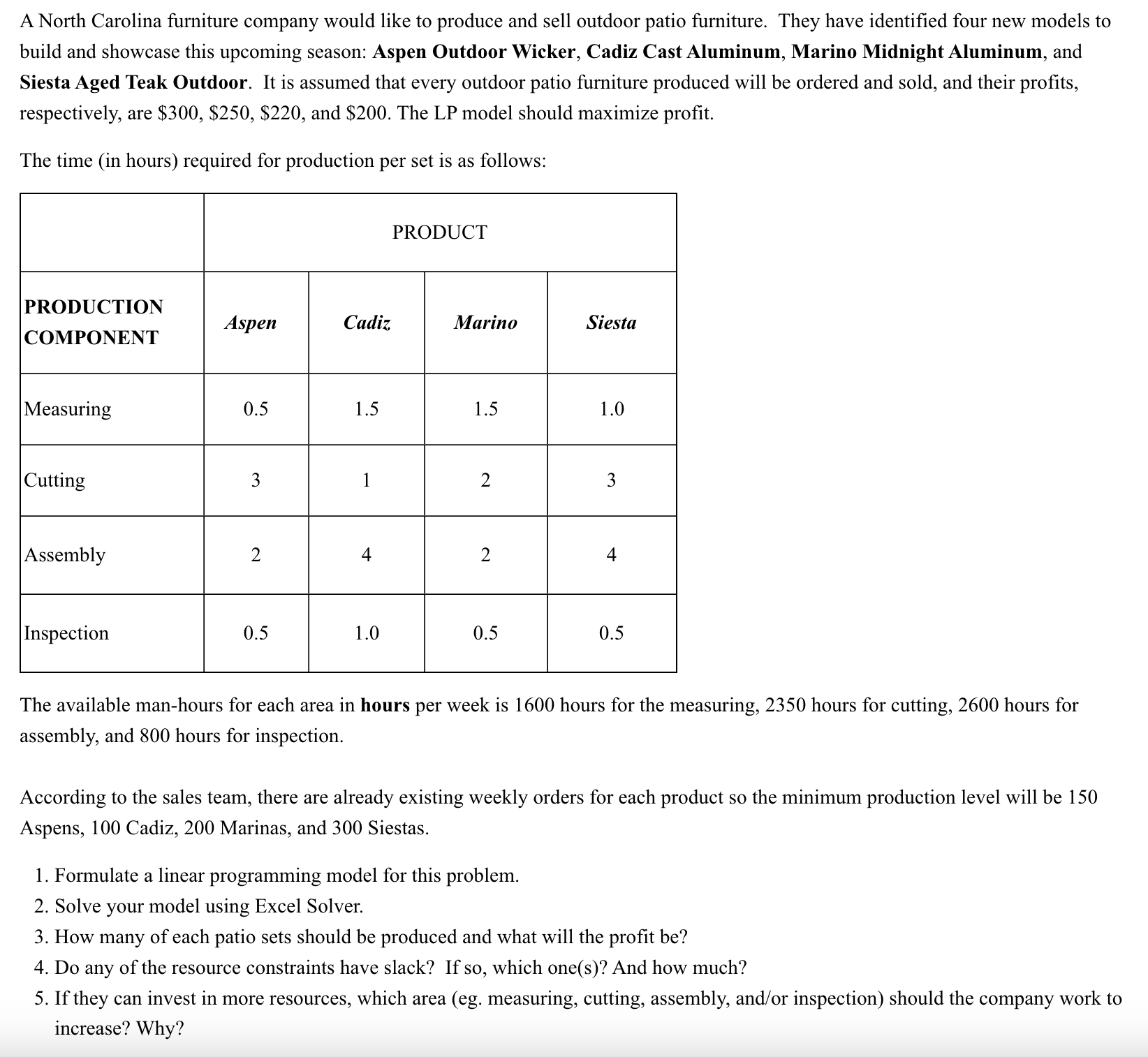

A North Carolina furniture company would like to produce and sell outdoor patio furniture. They have identified four new models to build and showcase this upcoming season: Aspen Outdoor Wicker, Cadiz Cast Aluminum, Marino Midnight Aluminum, and Siesta Aged Teak Outdoor. It is assumed that every outdoor patio furniture produced will be ordered and sold, and their profits, respectively, are $300,$250,$220, and $200. The LP model should maximize profit. The time (in hours) required for production per set is as follows: The available man-hours for each area in hours per week is 1600 hours for the measuring, 2350 hours for cutting, 2600 hours for assembly, and 800 hours for inspection. According to the sales team, there are already existing weekly orders for each product so the minimum production level will be 150 Aspens, 100 Cadiz, 200 Marinas, and 300 Siestas. 1. Formulate a linear programming model for this problem. 2. Solve your model using Excel Solver. 3. How many of each patio sets should be produced and what will the profit be? 4. Do any of the resource constraints have slack? If so, which one(s)? And how much? 5. If they can invest in more resources, which area (eg. measuring, cutting, assembly, and/or inspection) should the company work to increase? Why? A North Carolina furniture company would like to produce and sell outdoor patio furniture. They have identified four new models to build and showcase this upcoming season: Aspen Outdoor Wicker, Cadiz Cast Aluminum, Marino Midnight Aluminum, and Siesta Aged Teak Outdoor. It is assumed that every outdoor patio furniture produced will be ordered and sold, and their profits, respectively, are $300,$250,$220, and $200. The LP model should maximize profit. The time (in hours) required for production per set is as follows: The available man-hours for each area in hours per week is 1600 hours for the measuring, 2350 hours for cutting, 2600 hours for assembly, and 800 hours for inspection. According to the sales team, there are already existing weekly orders for each product so the minimum production level will be 150 Aspens, 100 Cadiz, 200 Marinas, and 300 Siestas. 1. Formulate a linear programming model for this problem. 2. Solve your model using Excel Solver. 3. How many of each patio sets should be produced and what will the profit be? 4. Do any of the resource constraints have slack? If so, which one(s)? And how much? 5. If they can invest in more resources, which area (eg. measuring, cutting, assembly, and/or inspection) should the company work to increase? Why

A North Carolina furniture company would like to produce and sell outdoor patio furniture. They have identified four new models to build and showcase this upcoming season: Aspen Outdoor Wicker, Cadiz Cast Aluminum, Marino Midnight Aluminum, and Siesta Aged Teak Outdoor. It is assumed that every outdoor patio furniture produced will be ordered and sold, and their profits, respectively, are $300,$250,$220, and $200. The LP model should maximize profit. The time (in hours) required for production per set is as follows: The available man-hours for each area in hours per week is 1600 hours for the measuring, 2350 hours for cutting, 2600 hours for assembly, and 800 hours for inspection. According to the sales team, there are already existing weekly orders for each product so the minimum production level will be 150 Aspens, 100 Cadiz, 200 Marinas, and 300 Siestas. 1. Formulate a linear programming model for this problem. 2. Solve your model using Excel Solver. 3. How many of each patio sets should be produced and what will the profit be? 4. Do any of the resource constraints have slack? If so, which one(s)? And how much? 5. If they can invest in more resources, which area (eg. measuring, cutting, assembly, and/or inspection) should the company work to increase? Why? A North Carolina furniture company would like to produce and sell outdoor patio furniture. They have identified four new models to build and showcase this upcoming season: Aspen Outdoor Wicker, Cadiz Cast Aluminum, Marino Midnight Aluminum, and Siesta Aged Teak Outdoor. It is assumed that every outdoor patio furniture produced will be ordered and sold, and their profits, respectively, are $300,$250,$220, and $200. The LP model should maximize profit. The time (in hours) required for production per set is as follows: The available man-hours for each area in hours per week is 1600 hours for the measuring, 2350 hours for cutting, 2600 hours for assembly, and 800 hours for inspection. According to the sales team, there are already existing weekly orders for each product so the minimum production level will be 150 Aspens, 100 Cadiz, 200 Marinas, and 300 Siestas. 1. Formulate a linear programming model for this problem. 2. Solve your model using Excel Solver. 3. How many of each patio sets should be produced and what will the profit be? 4. Do any of the resource constraints have slack? If so, which one(s)? And how much? 5. If they can invest in more resources, which area (eg. measuring, cutting, assembly, and/or inspection) should the company work to increase? Why Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started