Answered step by step

Verified Expert Solution

Question

1 Approved Answer

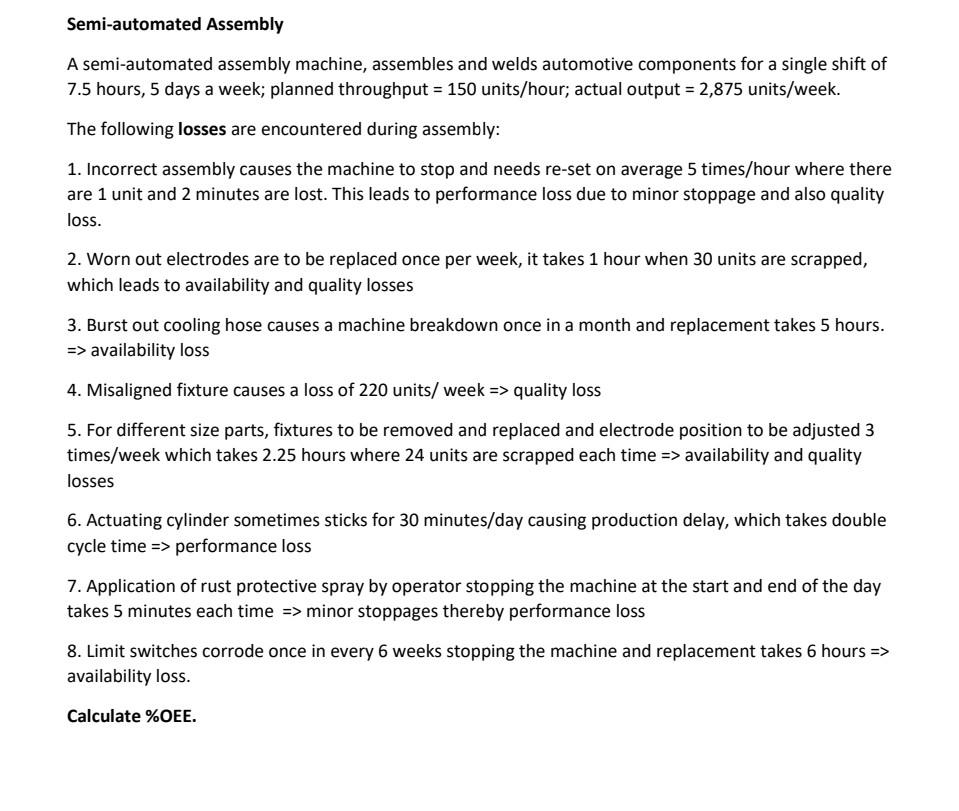

A semi-automated assembly machine, assembles and welds automotive components for a single shift of 7.5 hours, 5 days a week; planned throughput =150 units/hour; actual

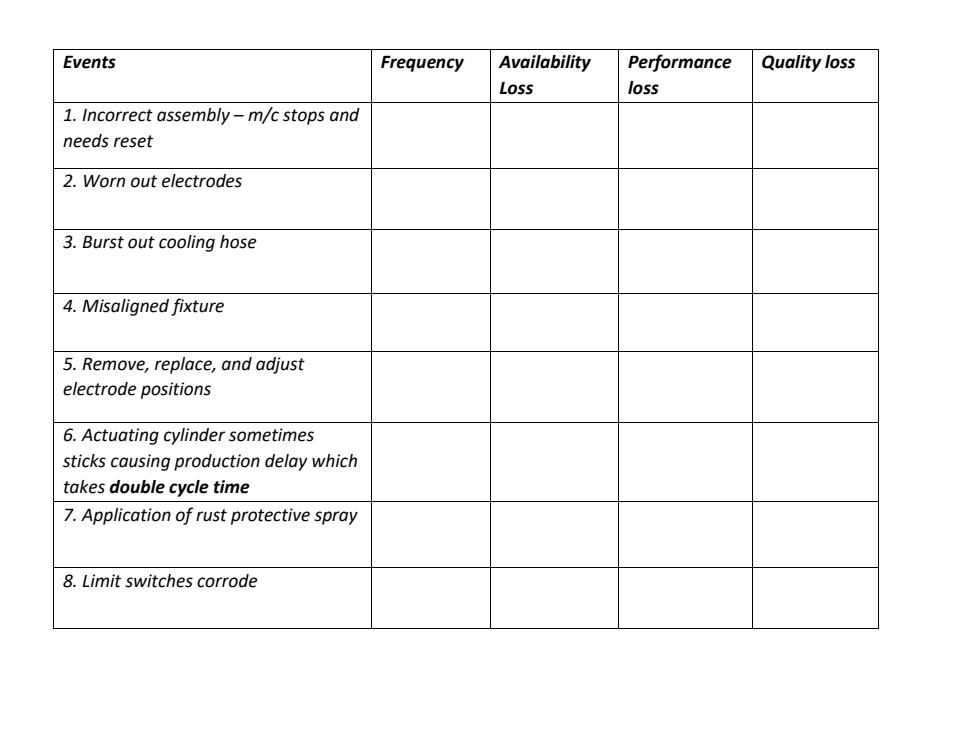

A semi-automated assembly machine, assembles and welds automotive components for a single shift of 7.5 hours, 5 days a week; planned throughput =150 units/hour; actual output =2,875 units/week. The following losses are encountered during assembly: 1. Incorrect assembly causes the machine to stop and needs re-set on average 5 times/hour where there are 1 unit and 2 minutes are lost. This leads to performance loss due to minor stoppage and also quality loss. 2. Worn out electrodes are to be replaced once per week, it takes 1 hour when 30 units are scrapped, which leads to availability and quality losses 3. Burst out cooling hose causes a machine breakdown once in a month and replacement takes 5 hours. 4. Misaligned fixture causes a loss of 220 units/ week > quality loss 5. For different size parts, fixtures to be removed and replaced and electrode position to be adjusted 3 times/week which takes 2.25 hours where 24 units are scrapped each time a availability and quality losses 6. Actuating cylinder sometimes sticks for 30 minutes/day causing production delay, which takes double cycle time > performance loss 7. Application of rust protective spray by operator stopping the machine at the start and end of the day takes 5 minutes each time > minor stoppages thereby performance loss 8. Limit switches corrode once in every 6 weeks stopping the machine and replacement takes 6 hours > availability loss. Calculate \%OEE

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started