A solid shaft for a cement kiln made from mild steel must be 96 cm long and must survive continuous operation for one year

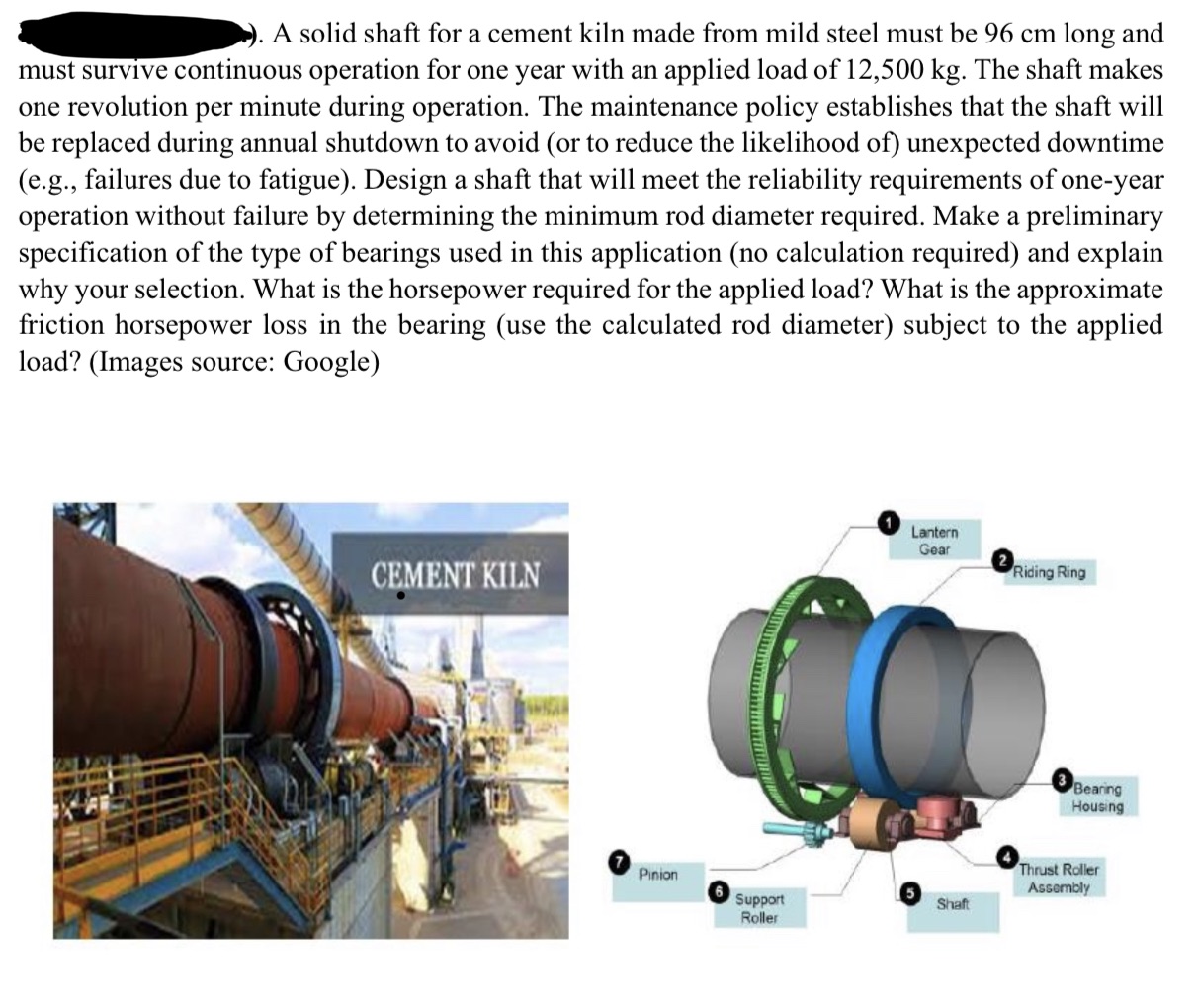

A solid shaft for a cement kiln made from mild steel must be 96 cm long and must survive continuous operation for one year with an applied load of 12,500 kg. The shaft makes one revolution per minute during operation. The maintenance policy establishes that the shaft will be replaced during annual shutdown to avoid (or to reduce the likelihood of) unexpected downtime (e.g., failures due to fatigue). Design a shaft that will meet the reliability requirements of one-year operation without failure by determining the minimum rod diameter required. Make a preliminary specification of the type of bearings used in this application (no calculation required) and explain why your selection. What is the horsepower required for the applied load? What is the approximate friction horsepower loss in the bearing (use the calculated rod diameter) subject to the applied load? (Images source: Google) Lantern Gear CEMENT KILN Riding Ring Pinion Support Roller Shaft Bearing Housing Thrust Roller Assembly

Step by Step Solution

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started