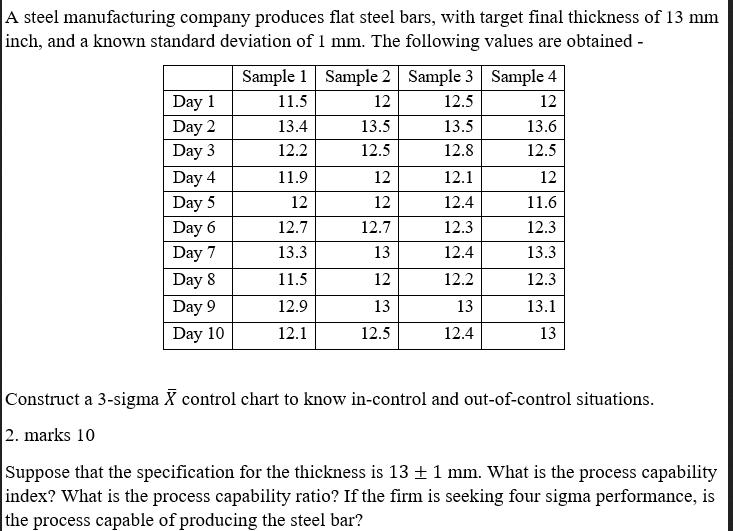

A steel manufacturing company produces flat steel bars, with target final thickness of 13 mm inch, and a known standard deviation of 1 mm.

A steel manufacturing company produces flat steel bars, with target final thickness of 13 mm inch, and a known standard deviation of 1 mm. The following values are obtained - Sample 1 Sample 2 Sample 3 Sample 4 Day 1 11.5 12 12.5 12 Day 2 13.4 13.5 13.5 13.6 Day 3 12.2 12.5 12.8 12.5 Day 4 11.9 12 12.1 12 Day 5 12 12 12.4 11.6 Day 6 12.7 12.7 12.3 12.3 Day 7 13.3 13 12.4 13.3 Day 8 11.5 12 12.2 12.3 Day 9 12.9 13 13 13.1 Day 10 12.1 12.5 12.4 13 Construct a 3-sigma X control chart to know in-control and out-of-control situations. 2. marks 10 Suppose that the specification for the thickness is 13 + 1 mm. What is the process capability index? What is the process capability ratio? If the firm is seeking four sigma performance, is the process capable of producing the steel bar?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started