Question: A unit load AS/RS for work-in-process storage in a factory must be designed to store 1,000 pallet loads, with an allowance of no less than

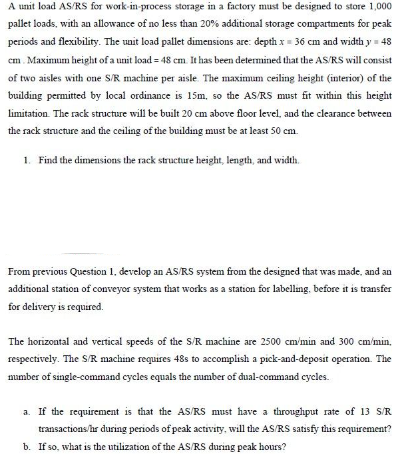

A unit load AS/RS for work-in-process storage in a factory must be designed to store 1,000 pallet loads, with an allowance of no less than 20% additional storage compartments for peak periods and flexibility. The unit load pallet dimensions are: depth x=36cm and width y=48 cm. Maximum height of a unit load =48cm. It has been determined that the AS/RS will consist of two aisles with one S/R machine per aisle. The maximum ceiling height (interior) of the building permitted by local ordinance is 15m, so the AS/RS must fit within this height limitation. The rack structure will be built 20cm above floor level, and the clearance between the rack structure and the ceiling of the building must be at least 50cm. 1. Find the dimensions the rack structure height, length, and width. From previous Question 1, develop an AS/RS system from the designed that was made, and an additional station of conveyor system that works as a station for labelling, before it is transfer for delivery is required. The horizontal and vertical speeds of the S/R machine are 2500cm/min and 300cm/min, respectively. The S/R machine requires 48s to accomplish a pick-and-deposit operation. The number of single-command cycles equals the number of dual-command cycles. a. If the requirement is that the AS/RS must have a throughput rate of 13S/R transactions/hr during periods of peak activity, will the AS/RS satisfy this requirement? b. If so, what is the utilization of the AS/RS during peak hours

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts