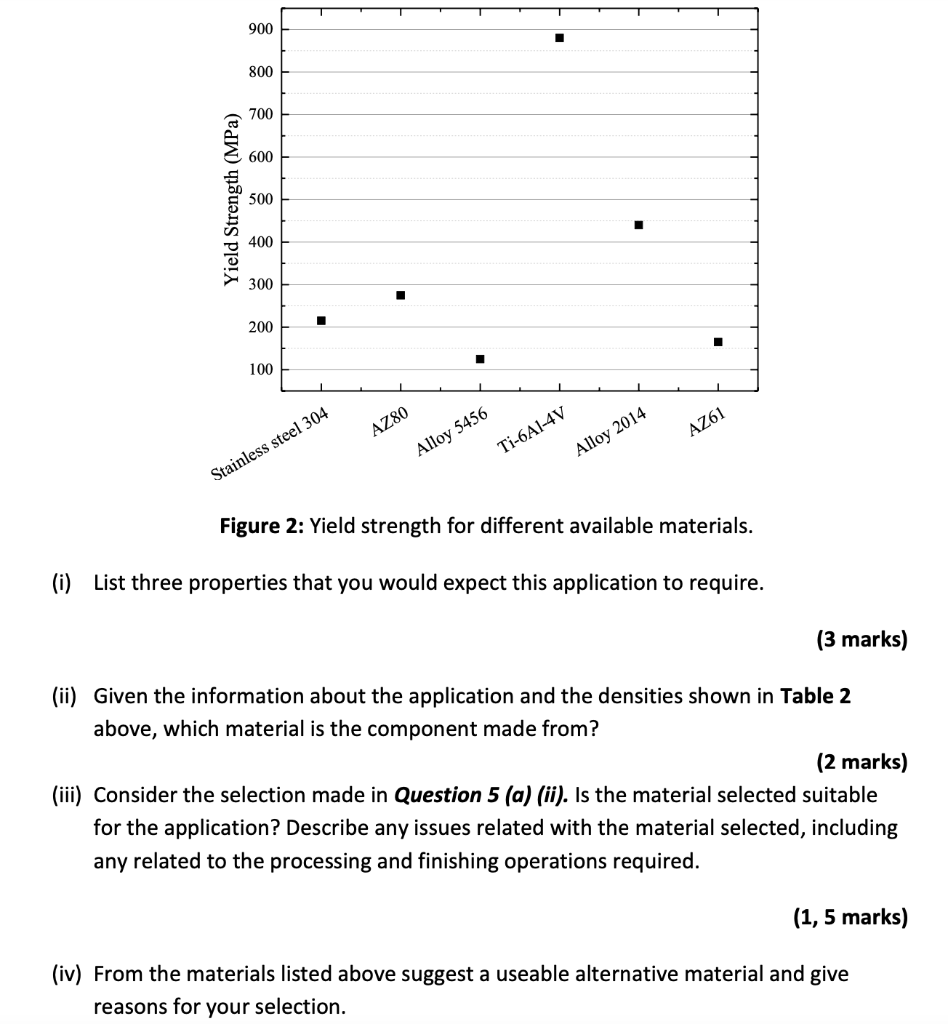

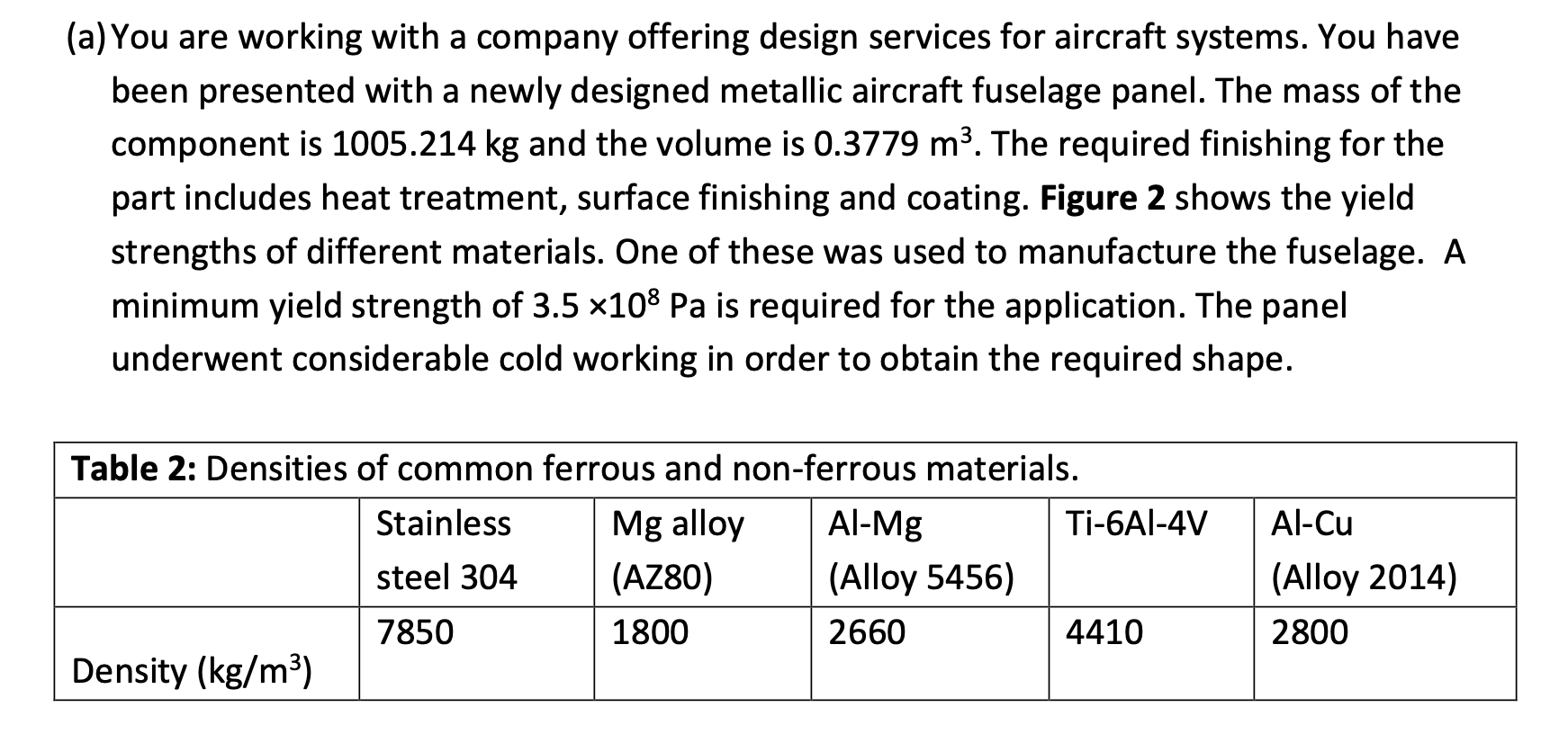

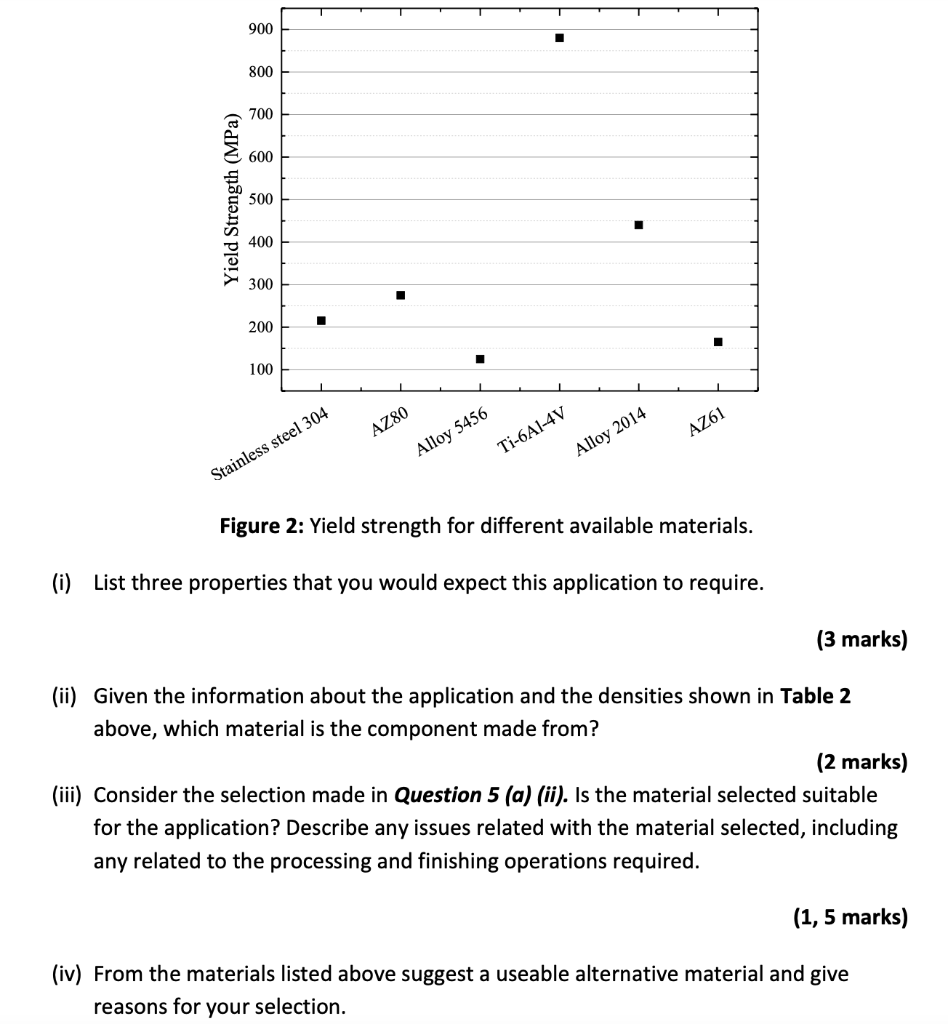

(a) You are working with a company offering design services for aircraft systems. You have been presented with a newly designed metallic aircraft fuselage panel. The mass of the component is 1005.214 kg and the volume is 0.3779 m3. The required finishing for the part includes heat treatment, surface finishing and coating. Figure 2 shows the yield strengths of different materials. One of these was used to manufacture the fuselage. A minimum yield strength of 3.5 x108 Pa is required for the application. The panel underwent considerable cold working in order to obtain the required shape. Table 2: Densities of common ferrous and non-ferrous materials. Stainless Mg alloy Al-Mg Ti-6Al-4V steel 304 (AZ80) (Alloy 5456) 7850 1800 2660 4410 Density (kg/m3) Al-Cu (Alloy 2014) 2800 900 800 700 600 Yield Strength (MPa) 500 400 300 200 1 100 AZ80 AZ61 Alloy 5456 Ti-6A1-4V Alloy 2014 Stainless steel 304 Figure 2: Yield strength for different available materials. (i) List three properties that you would expect this application to require. (3 marks) (ii) Given the information about the application and the densities shown in Table 2 above, which material is the component made from? (2 marks) (iii) Consider the selection made in Question 5 (a)(ii). Is the material selected suitable for the application? Describe any issues related with the material selected, including any related to the processing and finishing operations required. (1, 5 marks) (iv) From the materials listed above suggest a useable alternative material and give reasons for your selection. (a) You are working with a company offering design services for aircraft systems. You have been presented with a newly designed metallic aircraft fuselage panel. The mass of the component is 1005.214 kg and the volume is 0.3779 m3. The required finishing for the part includes heat treatment, surface finishing and coating. Figure 2 shows the yield strengths of different materials. One of these was used to manufacture the fuselage. A minimum yield strength of 3.5 x108 Pa is required for the application. The panel underwent considerable cold working in order to obtain the required shape. Table 2: Densities of common ferrous and non-ferrous materials. Stainless Mg alloy Al-Mg Ti-6Al-4V steel 304 (AZ80) (Alloy 5456) 7850 1800 2660 4410 Density (kg/m3) Al-Cu (Alloy 2014) 2800