Answered step by step

Verified Expert Solution

Question

1 Approved Answer

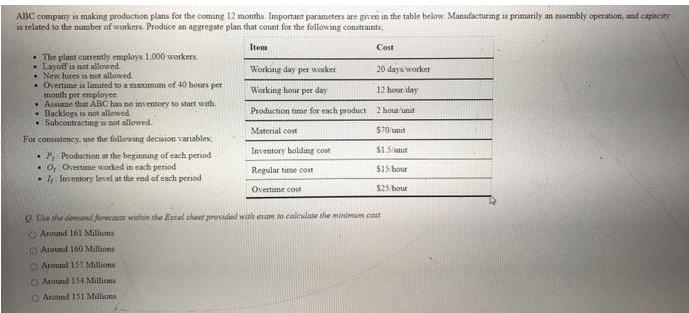

ABC company is making production plans for the coming 12 months. Important parameters are given in the table below Manufacturing is primarily an assembly

ABC company is making production plans for the coming 12 months. Important parameters are given in the table below Manufacturing is primarily an assembly operation, and capacity is related to the number of workers Produce an aggregate plan that count for the following constraints. - The plant currently employs 1,000 workers Layoff is not allowed. New hires is not allowed. Overtime is limited to a maximum of 40 hours per month per employee. Assume that ABC has no inventory to start with Backlogs is not allowed Subcontracting is not allowed For consistency, use the following decision variables, P. Production at the beginning of each period Or Overtime worked in each period Inventory level at the end of each period Item Around 159 Millions Around 154 Millions Around 151 Millions Cost 20 days worker 12 hour day Working day per worker Working hour per day Production time for each product 2 hour unit Material cost $70/unit Inventory holding cost $1 Sumit Regular time cost $15 hour Overtime cost $25 hour te the demand forecasts within the Excel sheet provided with exam to calculate the minimum cost Around 161 Millions Around 160 Millions

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The answer is Around 154 Million To calculate the minimum cost ABC needs to consider the following factors 1 Production ABC needs to decide the number ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started