ACME Trailers, Inc. builds tow-behind trailers for business and recreational use. The dimensions of the trailers are 6ft wide by 12ft long by 5ft tall.

ACME Trailers, Inc. builds tow-behind trailers for business and recreational use. The dimensions of the trailers are 6ft wide by 12ft long by 5ft tall. The trailers are primarily constructed using sheet metal (from cold – rolled steel), metal framing materials, door hardware and pre-fabricated axle – floor - hitch combinations. The top and sides of the trailers are made with 3 sheets of sheet metal measuring 4ft x 16ft (the sheets are wrapped around the top of the frame and down the sides of the trailer and are riveted, sealed, and fastened together at the seams). The front and back door of the trailer are each made with a 6ft by 5ft piece of sheet metal. Each trailer uses 4 metal “U” frames, one pre-fabricated axle – floor - hitch combination, and one set of door hardware. The frames, pre-fabricated axle – floor - hitch combination, and door hardware are all outsourced and produced externally. The sheet metal is cut, primed, and treated by the company’s internal manufacturing operations.

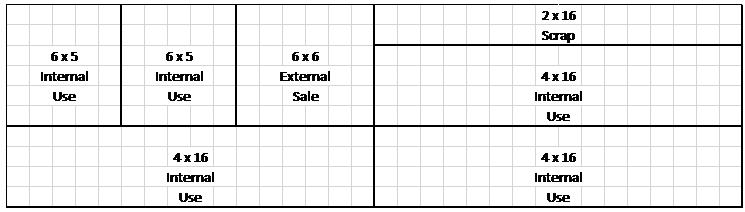

The Company has three manufacturing operations. Department A is responsible for the sheet metal fabrication. It utilizes a joint costing system as one large, externally supplied, roll of sheet metal is transformed into the five pieces of sheet metal needed for each trailer, plus an additional 6ft x 6ft sheet that is sold externally to a competitor for their trailer fabrication, plus a 2ft x 16ft sheet of fragment metal that is sold externally before for fragment. The metal is weather treated and primed in this department, aside from being cut. Department B is the assembly department, it takes the sheet metal produced by Department A and combines it with the externally purchased metal “U” frames, pre-fabricated axle – floor - hitch combinations, and door hardware. Various screws, rivets, glue, paint and other miscellany (indirect materials) are also used in this process. These are lumped with other conversion costs. Since the products of the assembly process are uniform, this department utilizes a weighted average process costing system. The final department (Department C) is the customization department. In this department, special customized features are made to trailers based upon the customer’s order. Typical customization includes customized paint jobs, modifications to the interior of the trailer (e.g., installation of peg board, storage compartments, and specialized electrical outlets), and other external modifications. Some trailers are sold to the mass-market as is after completion in Department B while others are transferred to Department C for customization. Since Department C produces unique products, it utilizes a job – costing system.

Part 1 – Department A

Department A purchases the sheet metal externally. The Department typically begins the period with some raw materials on hand, although management tries to minimize the raw materials inventory, and never has any work in process as the production process only takes a full day to perform. The department began the month with no finished product inventory. Three accounts are maintained for this: 6 x 5 Inventory, 6 x 6 Inventory, and 4 x 16 Inventory. Aside from raw materials, labor and overhead (machine depreciation, primer and other indirect materials, supervision, rent) are also incurred in this department. The raw materials are purchased in rolls of 10ft x 32ft sheets. To begin the month, the Department began with 1,027 sheets of raw material at an average cost of $96 per sheet. Raw materials are accounted for using a weighted average system. Aside from the 2ft x 16ft portion of fragment from each sheet of raw materials, the company expects, on average, to have 2% of full sheets result in fragment due to production errors, inconsistency in materials, etc. Since the fragment has insignificant monetary value, it is treated as a by-product, is not immediately inventoried, and is recognized as other income when fragment is sold. The company began the period with 315 square feet of fragment. Indirect materials (primer, treatment chemicals) are not inventoried as they are a small cost of the production process and very little is typically on hand from one period to the next. Below is the layout of how the sheets are cut.

For the sake of manufacturing efficiency, the entire sheet is treated and primed before it is cut. This causes the manufacturing process to be much more efficient but also makes the value of the fragment lower. In regard to the joint costing system, the company currently employs a physical measure method for costing utilizing square footage. The Company has considered using a sales price at split off method since external pricing is available for all of the company’s components. Since the production process is fairly quick and overall production and overhead is fairly level from one period to the next, the company uses actual overhead for costing purposes.

During the month, the Department A incurred the following events:

1. On the first of the month, the company purchased, on account, 1,500 sheets of raw material at a cost of $100 per sheet.

2. On the fifteenth of the month, the company purchased, on account, an additional 2,000 sheets of raw material at a cost of $102 per sheet.

3. Throughout the month, 4,124 sheets were moved from raw materials and put into production (cutting, priming, treatment). 74 of these sheets were damaged at some point in the production phase and were completely fragmented. Finished and cut sheets were placed into the three inventory accounts of 6 x 5 Inventory, 6 x 6 Inventory, and 4 x 16 Inventory.

4. At the end of month, all of the fragment on hand (including beginning fragment and the fragment produced during the month) was sold on account for $0.06 per square foot.

5. Depreciation of the painting and cutting equipment amounted to $15,000 for the month.

6. Supervisory wages and benefits for the department amounted to $15,134 for the month. These will be paid on the first of the following month.

7. Production labor and benefits for the department amounted to $101,324 for the month. These will also be paid on the first of the following month.

8. Indirect materials (primer and treatment chemicals) were purchased, on account, in the amount of $7,798 and used in production.

9. Rent for Department A’s facility amounted to $25,000 for the month. This rent was prepaid at the end of the prior month.

10. Payables totaling $12,245, the prior month’s accrued direct labor of $105,345, the prior month’s accrued supervision of $16,767, and the next month’s rent of $25,000 were all paid with cash during the month.

11. All work in process inventory was completed and transferred to the 3 finished goods accounts before month end.

12. 3,500 sheets of the 6 x 6 finished metal were sold on account to the external vendor at a price of $20.45 per sheet.

13. Receivables totaling $35,167 were collected.

Required

A. Calculate the total manufacturing costs incurred for the month for the joint costing system. Be sure to include all raw materials, direct labor, and overhead costs. Show work.

B. Draw a diagram detailing the physical flow of materials into production for month and the outputs from the production process and the associated costs.

C. For each of the three final products, allocate the costs incurred from A using the physical measures method (sq foot). Break these allocations down into a cost per sheet as well.

D. The CFO has asked you to also perform a sales price at split-off analysis to allocate joint costs to see how that method might differ. For this method, assume a 6 x 6 sheet has an external sales price of $20.45, a 6 x 5 sheet has an external sales price of $19.95, and the 4 x 16 sheet has an external sales price of $35.12. Repeat what you did in C using this methodology.

E. Was the company’s “spoilage” or fragment within standards? Would it be considered normal or abnormal? How is this being accounted for? How should it be accounted for if it were the opposite case?

F. Record double-sided entries for events 1 – 13. What are the ending balances of raw materials inventory and the three “finished goods” inventory accounts?

G. The Department’s accounting system basically utilizes actual direct materials, labor and overhead for costing measurement. Discuss how this system would differ if the company used a normal cost system. Discuss how the company’s methodology would differ if it employed a standard cost system.

6x5 Internal Use 6x5 Internal Use 4x 16 Internal Use 6x6 External Sale 2 x 16 Scrap 4x 16 Internal Use 4x 16 Internal Use

Step by Step Solution

3.34 Rating (148 Votes )

There are 3 Steps involved in it

Step: 1

Deloitte Answer workings Begining of Mouth 96 perfet opening stocle op Rawmaterdal 1027 sheet ...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started