Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A)compute the order quantities at the two locations and the total annual variable inventory cost by solving without inventory coordination two separate optimization problems using

A)compute the order quantities at the two locations and the total annual variable inventory cost by solving without inventory coordination two separate optimization problems using the basic EOQ formula.

A)compute the order quantities at the two locations and the total annual variable inventory cost by solving without inventory coordination two separate optimization problems using the basic EOQ formula.

b Determine the coordinated order quantities and the total annual variable inventory cost by simultaneously optimizing both stages using the exact procedure discussed in class.

c. Compare the annual inventory costs for the inventory policies developed in parts(a)and(b).Willany of these policies result in inventory shortages? Justify your answer.

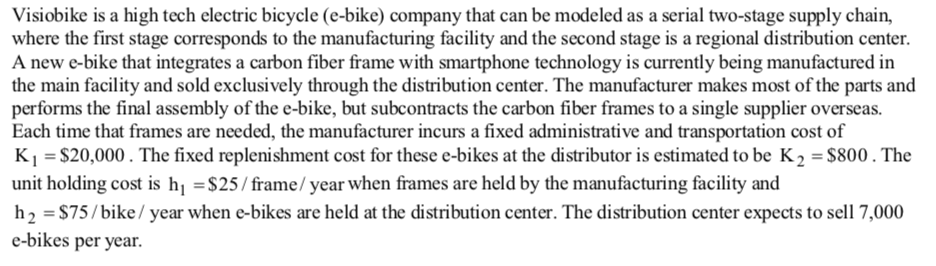

Visiobike is a high tech electric bicycle (e-bike) company that can be modeled as a serial two-stage supply chain, where the first stage corresponds to the manufacturing facility and the second stage is a regional distribution center. A new e-bike that integrates a carbon fiber frame with smartphone technology is currently being manufactured in the main facility and sold exclusively through the distribution center. The manufacturer makes most of the parts and performs the final assembly of the e-bike, but subcontracts the carbon fiber frames to a single supplier overseas. Each time that frames are needed, the manufacturer incurs a fixed administrative and transportation cost of K] = $20,000. The fixed replenishment cost for these e-bikes at the distributor is estimated to be K2 = $800. The unit holding cost is hy = $25/frame/ year when frames are held by the manufacturing facility and h 2 = $75/bike/ year when e-bikes are held at the distribution center. The distribution center expects to sell 7,000 e-bikes per year. Visiobike is a high tech electric bicycle (e-bike) company that can be modeled as a serial two-stage supply chain, where the first stage corresponds to the manufacturing facility and the second stage is a regional distribution center. A new e-bike that integrates a carbon fiber frame with smartphone technology is currently being manufactured in the main facility and sold exclusively through the distribution center. The manufacturer makes most of the parts and performs the final assembly of the e-bike, but subcontracts the carbon fiber frames to a single supplier overseas. Each time that frames are needed, the manufacturer incurs a fixed administrative and transportation cost of K] = $20,000. The fixed replenishment cost for these e-bikes at the distributor is estimated to be K2 = $800. The unit holding cost is hy = $25/frame/ year when frames are held by the manufacturing facility and h 2 = $75/bike/ year when e-bikes are held at the distribution center. The distribution center expects to sell 7,000 e-bikes per yearStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started