After many years of using a traditional costing system Adjusting Back Support Ltd. (ABS) has decided to adopt an activity-based costing (ABC) system. ABS produces

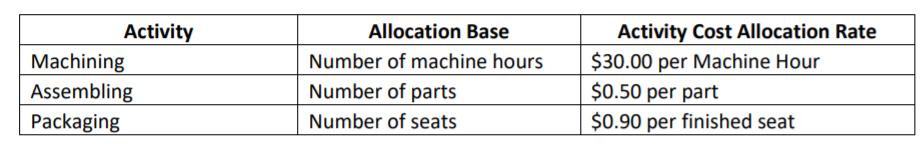

After many years of using a traditional costing system Adjusting Back Support Ltd. (ABS) has decided to adopt an activity-based costing (ABC) system. ABS produces an adjustable back support system that can be installed into cars. The competitive advantage that ABS has over other companies is its ability to take the existing seats and easily retro-fit them with the support system. Since this was their first attempt at ABC costing they have limited the number of cost pools to see if it is worth continuing to use ABC costing. The following is the costing information it has gathered to allocate their overhead costs.

Fiat Canada has begun a bidding process and asked ABS to bid on an annual shipment of 50,000 back supports for the seats in their new Fiat 500 series cars. There are five other companies submitting bids and being able to win this contract would help further establish ABS in the market. You are in charge of the bidding process and have obtained the following information from the production department.

Each back support per seat requires the following: 20 parts Direct materials per seat $11 50,000 seats would require 10,000 direct labour hours at $25/hour 400 machine hours would be required to fabricate the supports.

Required: 1) Compute the total cost of producing and packaging the 50,000 back supports. Be sure to include the average cost per support.

2) ABS bids on all their jobs using a 30% mark-up on total cost. What price will ABS submit as their bid to Fiat.

3) For comparison your manager would like you to calculate the bid price to Fiat if ABS was still using their traditional costing system. In the past the traditional costing system used $65 per direct labor hour as their predetermined overhead rate to allocate manufacturing overhead costs.

a. Compute the total cost of producing the 50,000 back supports using the traditional costing system.

b. Compute the average cost per support.

c. What bid price would ABS submit to Fiat if they were still using the traditional costing system?

4) Looking at your results in requirements 2 and 3 explain how ABC costing can help the company make better decisions about the bid price. Should ABS continue to use activity based costing?

Activity Cost Allocation Rate $30.00 per Machine Hour $0.50 per part Activity Allocation Base Machining Assembling Packaging Number of machine hours Number of parts Number of seats $0.90 per finished seat

Step by Step Solution

3.53 Rating (170 Votes )

There are 3 Steps involved in it

Step: 1

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started