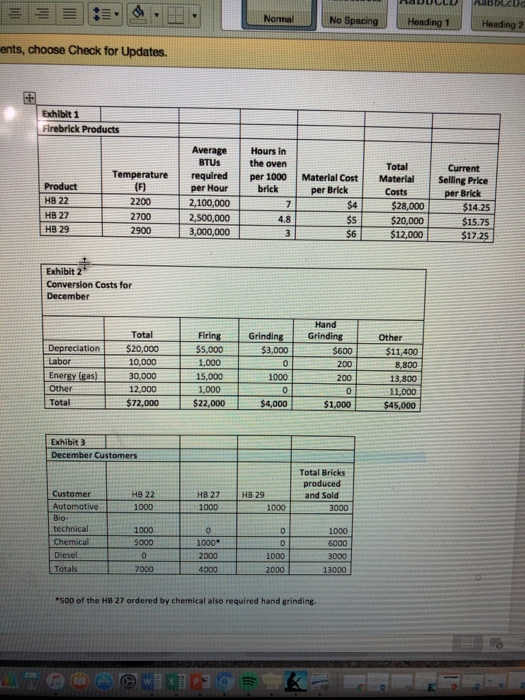

alibri To keep up-to -date with security updates, fices, and improvements, choose Cheok for Updates Hot Bricks Inc Hot Bricks inc. is a manufacturing company that provides high temperature bricks, which are specially produced to be used in high temperature and chemically corrosive environments. For years, Hot Bricks Inc. produced and sold only one product: the HB22, which is useful in environments up to 2200 degrees Fahrenheit. Through their research and development, they formulated and developed two new brick products, the HB27, and HB29. The new products use the same raw materials and the same equipment used to produce for the H822. The components that make up the three brick products are as follows high-purity refractory clay; alumina, for the higher temperature applications; and organic pellets that burn out during the manufacturing process and leave a uniform pore structure within the brick, which is desirable to their customers. Each brick product is "fired in an oven at a temperature just above their suggested use temperature to give them the desired properties. Once fired and cooled, the bricks go through a standard grinding process to make the bricks a final size of 9 x6 x3 Brick Making Process The manufacturing process begins with mixing, where the required materials are added. The bricks are then formed using molds. One batch of the mixing process produces 500 bricks in molds which are then allowed to air dry to remove excess moisture that could cause the bricks to crack in the firing process. The bricks then undergo firing at high temperatures in furnaces called kilns. These kilns have a number of burners through which fuel, natural gas, enters the furnace. The firing process involves several steps. Preheating removes the water leftover from the drying process. The temperature increases to the desired level for a period to cause a chemical and physical change to the brick. In the final cooling stage, the temperature decrease must be slow and steady to prevent bricks from cracking. Bricks fired to higher temperatures require more fuel because additional gas is required to achieve the needed higher temperature and because these bricks have to pass through the kiln more slowly After being fired and cooled, the bricks all pass through an automatic grinding machine which uses specialized grinding wheets to grind them to the desired size. Production managers have suggested that the new brick products require more time to grind and cause more wear on the grinding wheels. They believe it is because the higher temperature used to fire them makes them harder On occasion, customers require specially shaped bricks in order to supply the special shapes, bricks that have already been ground to 9 x5"x3" must undergo additional grinding by hand Manufacturing Cost Information Hot Bricks inc. developed their current costine system when they only produced the H822. That cost system has two main cost categories for producing brick products; material costs and conversion costs 2 of 1895 Words English (US) Dr No Spacing Heading 1 Heading 2 SubiteSubte Emp..Empha Title of higher priced raw material. When HBi only made the H8 22, all other manufacturing costs (labor and overhead) were allocated based on production volume using a traditional (simple) cost system based. In the year before adding new products, HBI determined the indirect cost of an HB 22 brick to be about $4.75. The ablity to provide the new products did not require additional capital investment. HBi simply had to add an additional manufacturing shift. That decision was expected to lower non-value added costs associated with warming up and cooling down the oven. Previously, HBI used fuel to warm the ovens up prior to use and cool the oven down at the end of the day. The process of cycling the furnace from cold to hot to cold each day also caused damage to the furnace. This damaged is minimized, but not eliminated, by controling how quickly the furnace heats up and cools down; however, I did require the around the clock, HBi expects to eliminate non-yalue added fuel and labor cost, as well as repairs due to use of fuel and labor to monitor the process. Now that the furnace is kept at an operating temperature cycling the temperature. in the be about $5.50 per brick. Management has not put their finger on specific reason for the higher costs. Pricing most recent analysis, which includes the new products, the average indirect cost was revealed to HBI's sets prices based on the product cost. Their markup is set to cover selling and administrative expenses and return a desired level of profit. Because on the new indirect cost information, the price on the HB22 has increased. The current prices have a 50% markup over the cost as present in Exhibit 1. Market conditions The H8-22 has enjoyed a long-standing reputation for quality and HBI management is committed to ensure the continued quality for the HB 22 and equal quality for its new products. All reports from customers suggest that HBi has succeeded in their quality goal. HBI management has been very pleased to see higher than expected growth and market share for their new H827 and H829 products. This was unexpected outcome was a particularly welcome surprise because HBI had become concerned about an unexpected decrease in demand for the H822. Additionally, the company has also seen an increase in the number of special shapes ordered Special order opportunity One of their sales forces has identified a company who is interested in "trying out" some HB 27s and HB 29s. The company wants to place a relatively large order, but is asking for a lower than normal price. if the customer is happy with the product, they will consider making HBi their primary supplier. The company will pay for shipping from the plant. No Spacing Heading 1Heading 2 Subtile Bubtlo Emp.. Title Complete and submit the following calculations You are the computer system, using the information you have conduct the following calculations Using values provided in the case, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type. Using a volume-based approach and the cost information for December provided in the exhibits, where each unit of brick is assigned the same costs regardless of the brick type, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type Using material cost as the allocation base for conversion costs and the information in the exhibits about December production, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type. 1. 2. 3. 4. Using an activity-based costing approach and information from the exhibits about December production, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type based on the manufacturing activities: Use BTU information for assigning fuel cost Choose an approach to assign special grinding costs Use volume-based costing for "other costs." Choose an activity base to assign grinding costs. . . . . Make sure to fully show your work iil! Normal No Spacin Heading 1 Hending 2 ents, choose Check for Updates. Exhibit 1 Flrebrick Products Average Hours in the oven Total Current Temperature requiredper1000 Material Cost MaterialSelling Price per Hour 2200 2,100,000 2,500,000 HB 29 | 2900 13,000,000 brick per Brick Costs per Brick 22 HB 27 $28,000$14.25 $15.75 $17.25 2700 4.8 $12,000 Exhibit 2 Conversion Costs for Hand Total tion 520,000 Energy (gas) 30,000 Grinding Grinding Other 3,000 1000 $4,000 $600 $11,400 8,800 13,800 11,000 $1,000$45,00o Labor 1,000 15,000 1,000 $22,000 Other Total 12,000 $72,000 December Customers Total Bricks Customer HB 22 1000 HB 27HB 29 1000 and Sold 1000 1000 2000 1000 7000 4000 500 of the HB 27 ordered by chemical also required hand grinding. alibri To keep up-to -date with security updates, fices, and improvements, choose Cheok for Updates Hot Bricks Inc Hot Bricks inc. is a manufacturing company that provides high temperature bricks, which are specially produced to be used in high temperature and chemically corrosive environments. For years, Hot Bricks Inc. produced and sold only one product: the HB22, which is useful in environments up to 2200 degrees Fahrenheit. Through their research and development, they formulated and developed two new brick products, the HB27, and HB29. The new products use the same raw materials and the same equipment used to produce for the H822. The components that make up the three brick products are as follows high-purity refractory clay; alumina, for the higher temperature applications; and organic pellets that burn out during the manufacturing process and leave a uniform pore structure within the brick, which is desirable to their customers. Each brick product is "fired in an oven at a temperature just above their suggested use temperature to give them the desired properties. Once fired and cooled, the bricks go through a standard grinding process to make the bricks a final size of 9 x6 x3 Brick Making Process The manufacturing process begins with mixing, where the required materials are added. The bricks are then formed using molds. One batch of the mixing process produces 500 bricks in molds which are then allowed to air dry to remove excess moisture that could cause the bricks to crack in the firing process. The bricks then undergo firing at high temperatures in furnaces called kilns. These kilns have a number of burners through which fuel, natural gas, enters the furnace. The firing process involves several steps. Preheating removes the water leftover from the drying process. The temperature increases to the desired level for a period to cause a chemical and physical change to the brick. In the final cooling stage, the temperature decrease must be slow and steady to prevent bricks from cracking. Bricks fired to higher temperatures require more fuel because additional gas is required to achieve the needed higher temperature and because these bricks have to pass through the kiln more slowly After being fired and cooled, the bricks all pass through an automatic grinding machine which uses specialized grinding wheets to grind them to the desired size. Production managers have suggested that the new brick products require more time to grind and cause more wear on the grinding wheels. They believe it is because the higher temperature used to fire them makes them harder On occasion, customers require specially shaped bricks in order to supply the special shapes, bricks that have already been ground to 9 x5"x3" must undergo additional grinding by hand Manufacturing Cost Information Hot Bricks inc. developed their current costine system when they only produced the H822. That cost system has two main cost categories for producing brick products; material costs and conversion costs 2 of 1895 Words English (US) Dr No Spacing Heading 1 Heading 2 SubiteSubte Emp..Empha Title of higher priced raw material. When HBi only made the H8 22, all other manufacturing costs (labor and overhead) were allocated based on production volume using a traditional (simple) cost system based. In the year before adding new products, HBI determined the indirect cost of an HB 22 brick to be about $4.75. The ablity to provide the new products did not require additional capital investment. HBi simply had to add an additional manufacturing shift. That decision was expected to lower non-value added costs associated with warming up and cooling down the oven. Previously, HBI used fuel to warm the ovens up prior to use and cool the oven down at the end of the day. The process of cycling the furnace from cold to hot to cold each day also caused damage to the furnace. This damaged is minimized, but not eliminated, by controling how quickly the furnace heats up and cools down; however, I did require the around the clock, HBi expects to eliminate non-yalue added fuel and labor cost, as well as repairs due to use of fuel and labor to monitor the process. Now that the furnace is kept at an operating temperature cycling the temperature. in the be about $5.50 per brick. Management has not put their finger on specific reason for the higher costs. Pricing most recent analysis, which includes the new products, the average indirect cost was revealed to HBI's sets prices based on the product cost. Their markup is set to cover selling and administrative expenses and return a desired level of profit. Because on the new indirect cost information, the price on the HB22 has increased. The current prices have a 50% markup over the cost as present in Exhibit 1. Market conditions The H8-22 has enjoyed a long-standing reputation for quality and HBI management is committed to ensure the continued quality for the HB 22 and equal quality for its new products. All reports from customers suggest that HBi has succeeded in their quality goal. HBI management has been very pleased to see higher than expected growth and market share for their new H827 and H829 products. This was unexpected outcome was a particularly welcome surprise because HBI had become concerned about an unexpected decrease in demand for the H822. Additionally, the company has also seen an increase in the number of special shapes ordered Special order opportunity One of their sales forces has identified a company who is interested in "trying out" some HB 27s and HB 29s. The company wants to place a relatively large order, but is asking for a lower than normal price. if the customer is happy with the product, they will consider making HBi their primary supplier. The company will pay for shipping from the plant. No Spacing Heading 1Heading 2 Subtile Bubtlo Emp.. Title Complete and submit the following calculations You are the computer system, using the information you have conduct the following calculations Using values provided in the case, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type. Using a volume-based approach and the cost information for December provided in the exhibits, where each unit of brick is assigned the same costs regardless of the brick type, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type Using material cost as the allocation base for conversion costs and the information in the exhibits about December production, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type. 1. 2. 3. 4. Using an activity-based costing approach and information from the exhibits about December production, calculate 1) the production cost, 2) the normal selling price, and proposed minimum price of each brick type based on the manufacturing activities: Use BTU information for assigning fuel cost Choose an approach to assign special grinding costs Use volume-based costing for "other costs." Choose an activity base to assign grinding costs. . . . . Make sure to fully show your work iil! Normal No Spacin Heading 1 Hending 2 ents, choose Check for Updates. Exhibit 1 Flrebrick Products Average Hours in the oven Total Current Temperature requiredper1000 Material Cost MaterialSelling Price per Hour 2200 2,100,000 2,500,000 HB 29 | 2900 13,000,000 brick per Brick Costs per Brick 22 HB 27 $28,000$14.25 $15.75 $17.25 2700 4.8 $12,000 Exhibit 2 Conversion Costs for Hand Total tion 520,000 Energy (gas) 30,000 Grinding Grinding Other 3,000 1000 $4,000 $600 $11,400 8,800 13,800 11,000 $1,000$45,00o Labor 1,000 15,000 1,000 $22,000 Other Total 12,000 $72,000 December Customers Total Bricks Customer HB 22 1000 HB 27HB 29 1000 and Sold 1000 1000 2000 1000 7000 4000 500 of the HB 27 ordered by chemical also required hand grinding