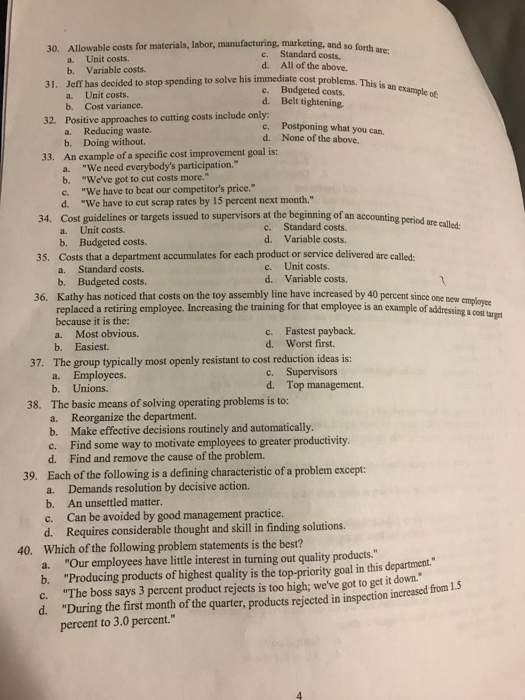

Allowable costs for materials, labor, manufacturing, marketing, and so forth are: Unit costs. Variable costs. Standard costs. All of the above. Jeff has decided to stop spending to solve his immediate cost problems. This is an example of: Unit costs. Cost variance. Budgeted costs. Belt tightening. Positive approaches to cutting costs include only: Reducing waste. Doing without. Postponing what you can. None of the above. An example of a specific cost improvement goal is: "We need everybody's participation." "We've got to cut costs more." "We have to beat our competitor's price." "We have to cut scrap rates by 15 percent next month." Cost guidelines or targets issued to supervisors at the beginning of an accounting period are called: Unit costs. Budgeted costs. Standard costs. Variable costs. Costs that a department accumulates for each product or service delivered are called: Standard costs. Budgeted costs. Unit costs. Variable costs. Kathy has noticed that costs on the toy assembly line have increased by 40 percent since one new employee replaced a retiring employee. Increasing the training for that employee is an example of addressing a cost target because it is the: Most obvious. Easiest. Fastest payback. Worst first. The group typically most openly resistant to cost reduction ideas is: Employees. Unions. Supervisors. Top management. The basic means of solving operating problems is to: Reorganize the department. Make effective decisions routinely and automatically. Find some way to motivate employees to greater productivity. Find and remove the cause of the problem. Each of the following is a defining characteristic of a problem except: Demands resolution by decisive action. An unsettled matter. Can be avoided by good management practice. Requires considerable thought and skill in finding solutions. Which of the following problem statements is the best? "Our employees have little interest in turning out quality products." "Producing products of highest quality is the top-priority goal in this department." "The boss says 3 percent product rejects is too high: we've got to get it down." "During the first month of the quarter, products rejected in inspection increased from 1.5 percent to 3.0 percent