Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Ammonia is produced from nitrogen and hydrogen by the following reversible reaction: N + 3H = 2NH3 A process flowsheet for an ammonia production

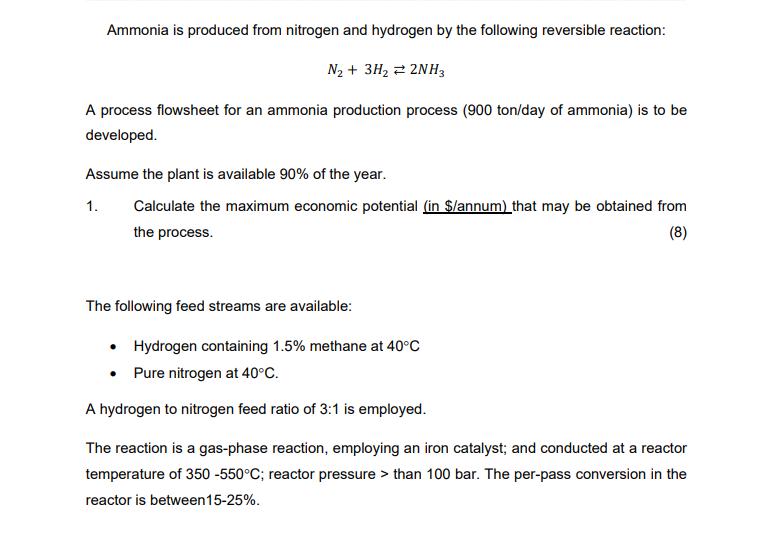

Ammonia is produced from nitrogen and hydrogen by the following reversible reaction: N + 3H = 2NH3 A process flowsheet for an ammonia production process (900 ton/day of ammonia) is to be developed. Assume the plant is available 90% of the year. Calculate the maximum economic potential (in $/annum) that may be obtained from the process. (8) 1. The following feed streams are available: Hydrogen containing 1.5% methane at 40C Pure nitrogen at 40C. A hydrogen to nitrogen feed ratio of 3:1 is employed. The reaction is a gas-phase reaction, employing an iron catalyst; and conducted at a reactor temperature of 350 -550C; reactor pressure > than 100 bar. The per-pass conversion in the reactor is between 15-25%. 2. 3. 4. 5. 6. List the boiling points of each component in the system and assign a destination code to each component (primary product, purge, fuel, waste, none etc.). How many feed streams and product streams are there? (5) Should the methane impurity be removed before the reaction? Justify your answer and discuss the implication of the decision. (3) Since the per pass conversion is low, what strategies could be utilized to increased recovery of valuable material(s)? (3) Draw and label an input-output structure for the process. Explain your reasoning for the selected structure. (5) What are the design variable(s) in this specific case? (1) 7. 8. 9. Perform a symbolic overall material balance for the process (based on variables in the input-output structure). (13) Plot the economic potential (in $/annum) as a function of the design variable. What is the environmental impact of the process? Economic data: Price ($/ton) Nitrogen 265 Hydrogen 1 250 Ammonia 720 Fuel gas 20 (9) (3) [50] Ammonia is produced from nitrogen and hydrogen by the following reversible reaction: N + 3H = 2NH3 A process flowsheet for an ammonia production process (900 ton/day of ammonia) is to be developed. Assume the plant is available 90% of the year. Calculate the maximum economic potential (in $/annum) that may be obtained from the process. (8) 1. The following feed streams are available: Hydrogen containing 1.5% methane at 40C Pure nitrogen at 40C. A hydrogen to nitrogen feed ratio of 3:1 is employed. The reaction is a gas-phase reaction, employing an iron catalyst; and conducted at a reactor temperature of 350 -550C; reactor pressure > than 100 bar. The per-pass conversion in the reactor is between 15-25%. 2. 3. 4. 5. 6. List the boiling points of each component in the system and assign a destination code to each component (primary product, purge, fuel, waste, none etc.). How many feed streams and product streams are there? (5) Should the methane impurity be removed before the reaction? Justify your answer and discuss the implication of the decision. (3) Since the per pass conversion is low, what strategies could be utilized to increased recovery of valuable material(s)? (3) Draw and label an input-output structure for the process. Explain your reasoning for the selected structure. (5) What are the design variable(s) in this specific case? (1) 7. 8. 9. Perform a symbolic overall material balance for the process (based on variables in the input-output structure). (13) Plot the economic potential (in $/annum) as a function of the design variable. What is the environmental impact of the process? Economic data: Price ($/ton) Nitrogen 265 Hydrogen 1 250 Ammonia 720 Fuel gas 20 (9) (3) [50] Ammonia is produced from nitrogen and hydrogen by the following reversible reaction: N + 3H = 2NH3 A process flowsheet for an ammonia production process (900 ton/day of ammonia) is to be developed. Assume the plant is available 90% of the year. Calculate the maximum economic potential (in $/annum) that may be obtained from the process. (8) 1. The following feed streams are available: Hydrogen containing 1.5% methane at 40C Pure nitrogen at 40C. A hydrogen to nitrogen feed ratio of 3:1 is employed. The reaction is a gas-phase reaction, employing an iron catalyst; and conducted at a reactor temperature of 350 -550C; reactor pressure > than 100 bar. The per-pass conversion in the reactor is between 15-25%. 2. 3. 4. 5. 6. List the boiling points of each component in the system and assign a destination code to each component (primary product, purge, fuel, waste, none etc.). How many feed streams and product streams are there? (5) Should the methane impurity be removed before the reaction? Justify your answer and discuss the implication of the decision. (3) Since the per pass conversion is low, what strategies could be utilized to increased recovery of valuable material(s)? (3) Draw and label an input-output structure for the process. Explain your reasoning for the selected structure. (5) What are the design variable(s) in this specific case? (1) 7. 8. 9. Perform a symbolic overall material balance for the process (based on variables in the input-output structure). (13) Plot the economic potential (in $/annum) as a function of the design variable. What is the environmental impact of the process? Economic data: Price ($/ton) Nitrogen 265 Hydrogen 1 250 Ammonia 720 Fuel gas 20 (9) (3) [50]

Step by Step Solution

★★★★★

3.53 Rating (190 Votes )

There are 3 Steps involved in it

Step: 1

Answer 2 Boiling Point Nitrogen gas 1958 degrees celcious NH 3 3334 degrees celcious H ydrogen 2529 degrees celcious To make a profit we must lower the initial quantity that must be fed and reuse unre...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started