An operations manager is trying to determine a production plan for the next week. There are three products (say, P, Q, and Q) to

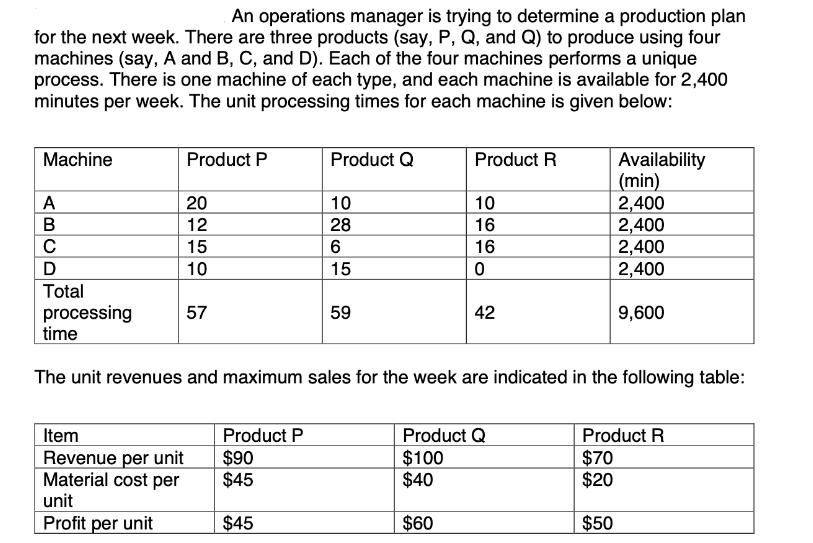

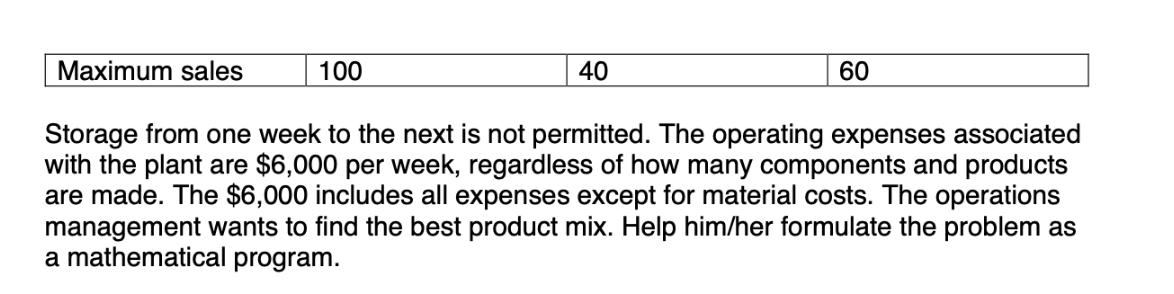

An operations manager is trying to determine a production plan for the next week. There are three products (say, P, Q, and Q) to produce using four machines (say, A and B, C, and D). Each of the four machines performs a unique process. There is one machine of each type, and each machine is available for 2,400 minutes per week. The unit processing times for each machine is given below: Machine Product P Item Revenue per unit Material cost per unit Profit per unit 20 12 A B C D Total processing time The unit revenues and maximum sales for the week are indicated in the following table: 15 10 57 Product Q Product P $90 $45 $45 10 28 6 15 Product R 59 10 16 16 0 42 Availability (min) 2,400 2,400 2,400 2,400 Product Q $100 $40 $60 9,600 Product R $70 $20 $50 Maximum sales 100 40 60 Storage from one week to the next is not permitted. The operating expenses associated with the plant are $6,000 per week, regardless of how many components and products are made. The $6,000 includes all expenses except for material costs. The operations management wants to find the best product mix. Help him/her formulate the problem as a mathematical program.

Step by Step Solution

3.32 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

To formulate the production planning problem as a linear programming problem we need to define decis...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started