Answered step by step

Verified Expert Solution

Question

1 Approved Answer

2. A chip shooter can place SMT (surface mount technology) components on circuit boards in 15 seconds. However, when the machine is changed from

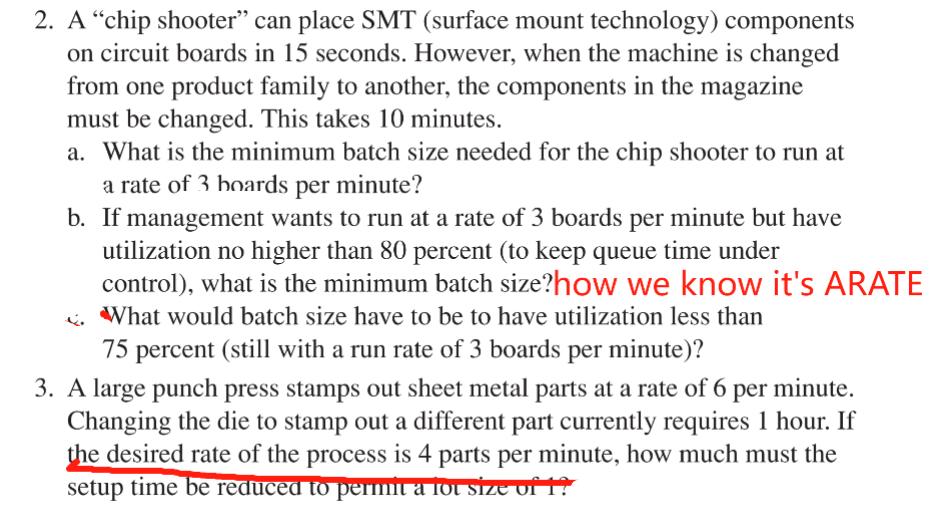

2. A "chip shooter" can place SMT (surface mount technology) components on circuit boards in 15 seconds. However, when the machine is changed from one product family to another, the components in the magazine must be changed. This takes 10 minutes. a. What is the minimum batch size needed for the chip shooter to run at a rate of 3 boards per minute? b. If management wants to run at a rate of 3 boards per minute but have utilization no higher than 80 percent (to keep queue time under control), what is the minimum batch size?how we know it's ARATE What would batch size have to be to have utilization less than 75 percent (still with a run rate of 3 boards per minute)? 3. A large punch press stamps out sheet metal parts at a rate of 6 per minute. Changing the die to stamp out a different part currently requires 1 hour. If the desired rate of the process is 4 parts per minute, how much must the setup time be reduced to permit a fot size of 1?

Step by Step Solution

★★★★★

3.47 Rating (170 Votes )

There are 3 Steps involved in it

Step: 1

Q2a To determine the minimum batch size needed for the chip shooter to run at a rate of 3 boards per minute we need to consider the time required for both the chip shooter operation and the component ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started