Question: ARTICLE REVIEW Write an article review about the attitudes and professionalism in Operations Management of the following article. Based on the selected company case/article/material, write

ARTICLE REVIEW

Write an article review about the attitudes and professionalism in Operations Management of the following article. Based on the selected company case/article/material, write 4 important parts:

- Introduce the case or article.

- Identify operations management issues.

- Analyze and discuss the issues.

- Elaborate lessons learnt from the case or article (compare and contrast the theoretical aspect/s vs real-life practical issues

- The length of this report should be a maximum of 2 pages.

- References must be written at the end of the write-up.

- Attach relevant appendices such as articles/papers/other pertinent information

-

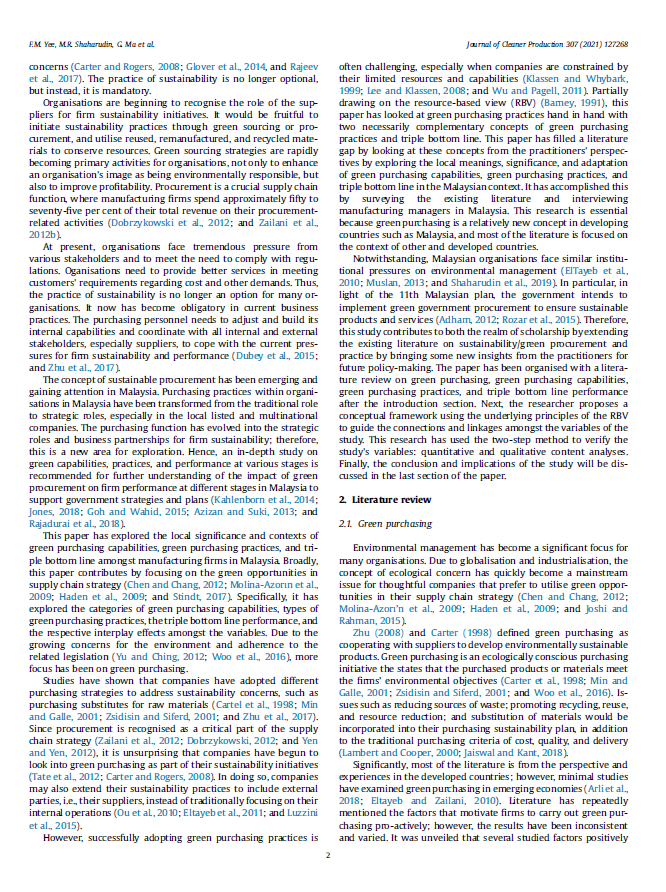

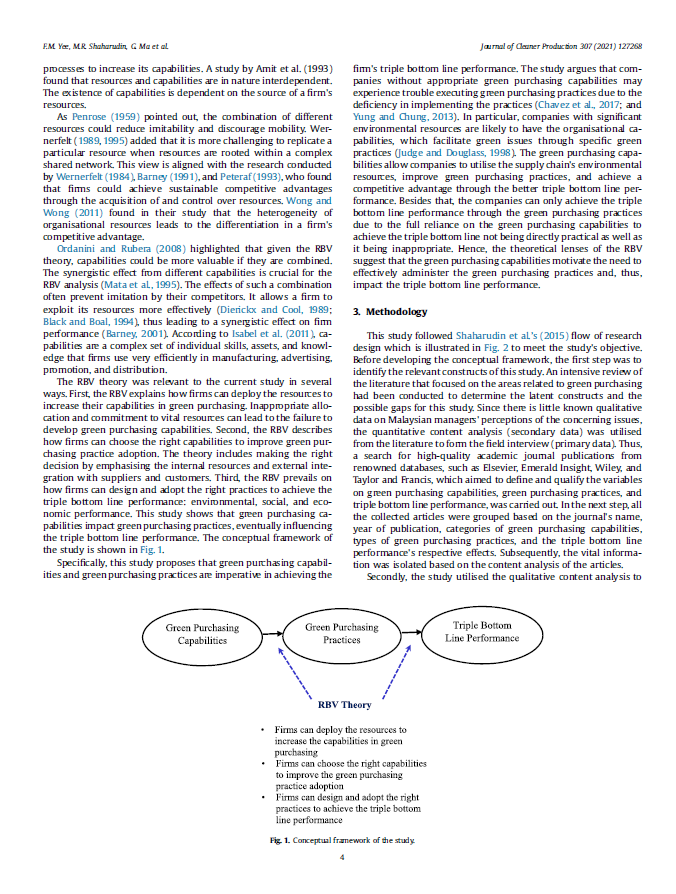

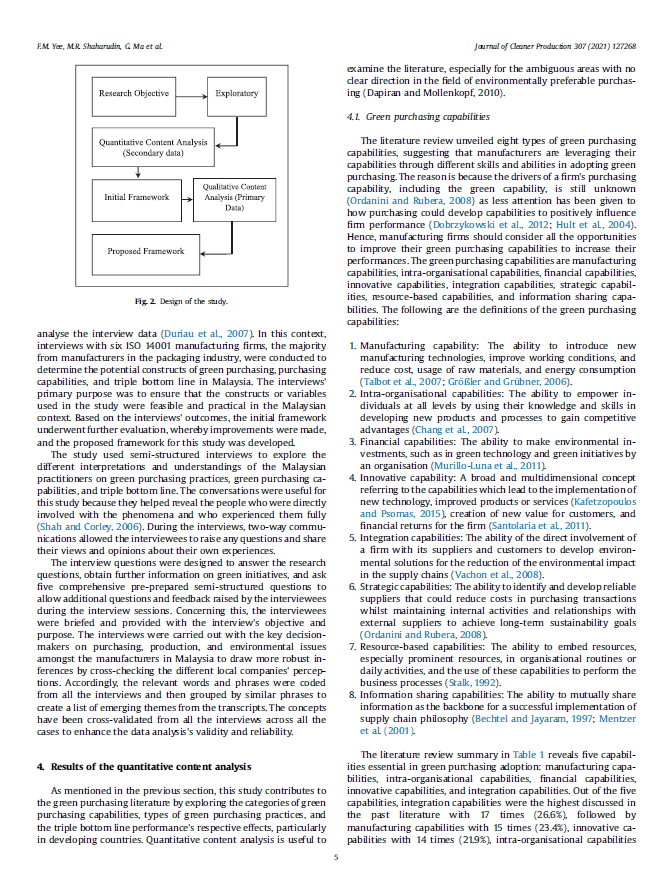

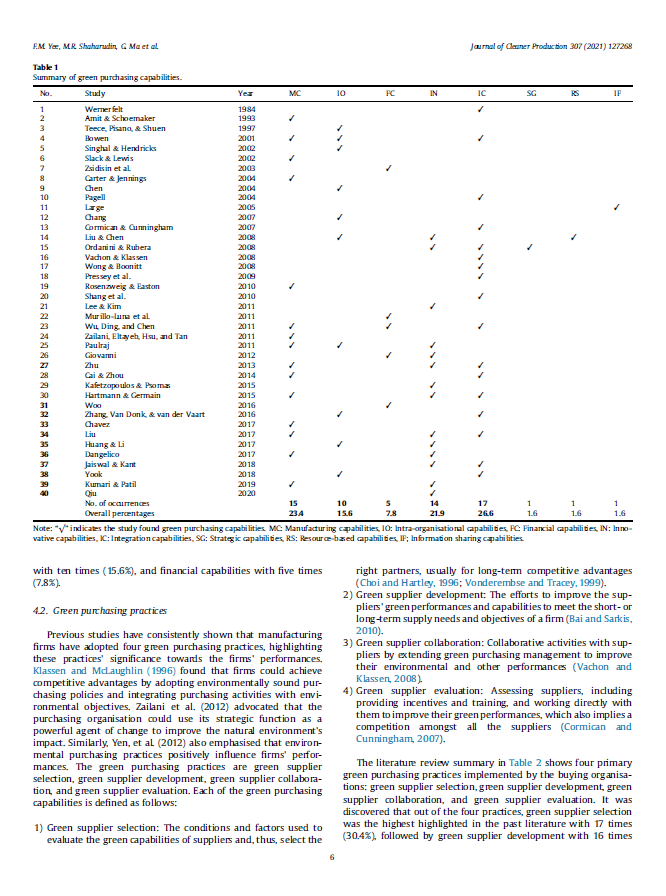

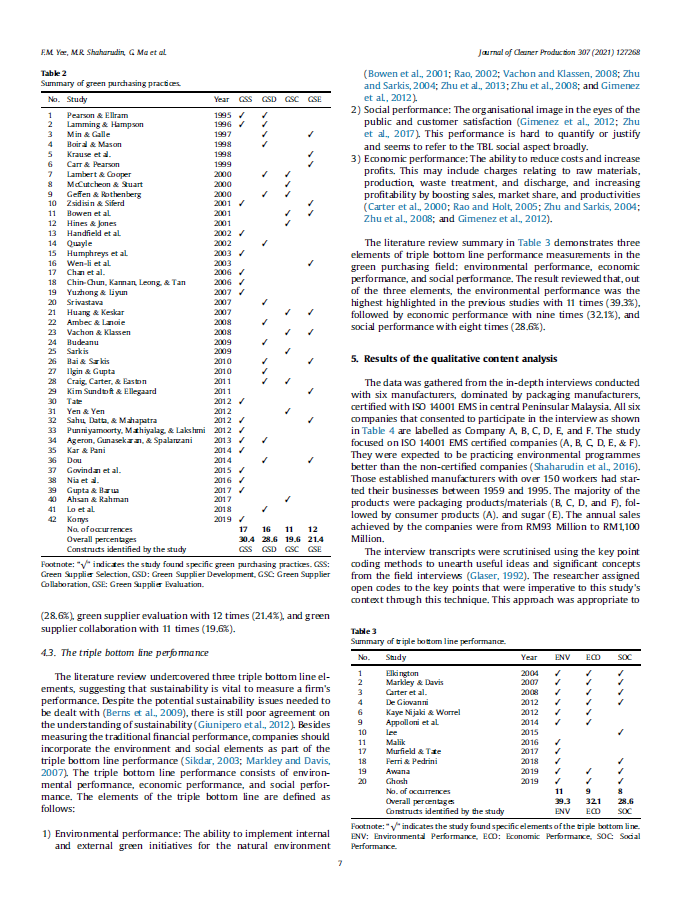

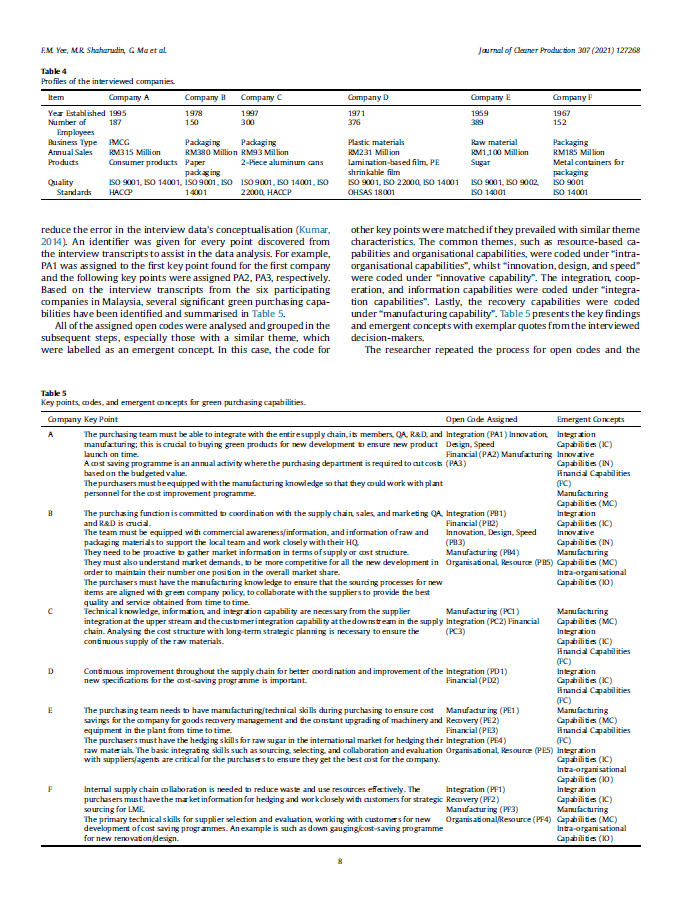

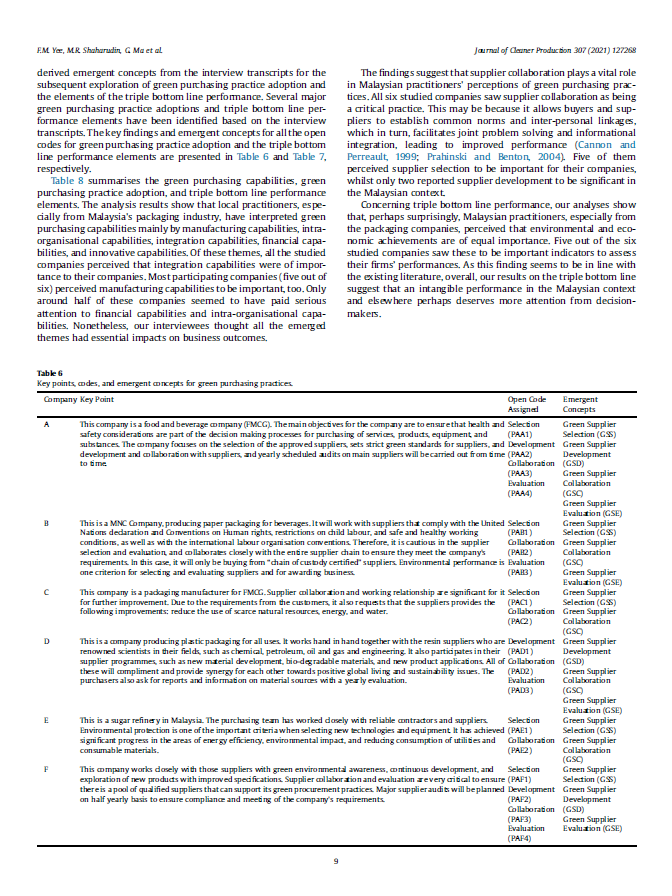

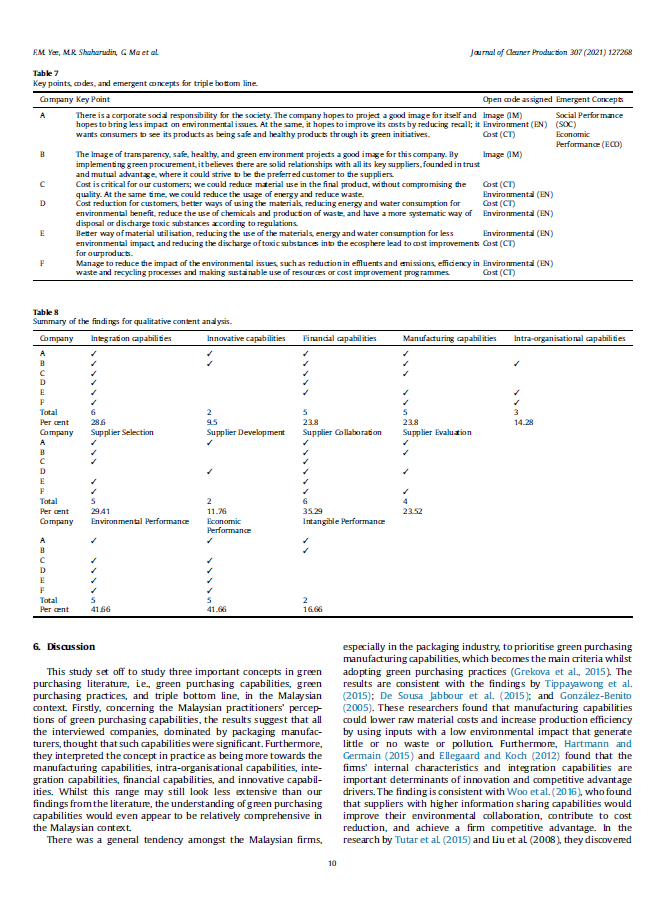

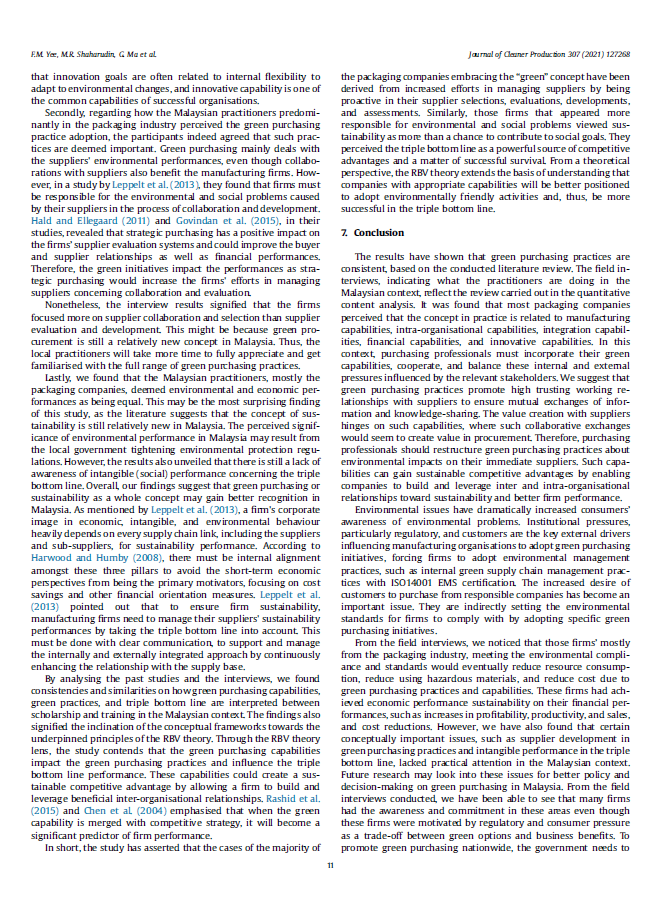

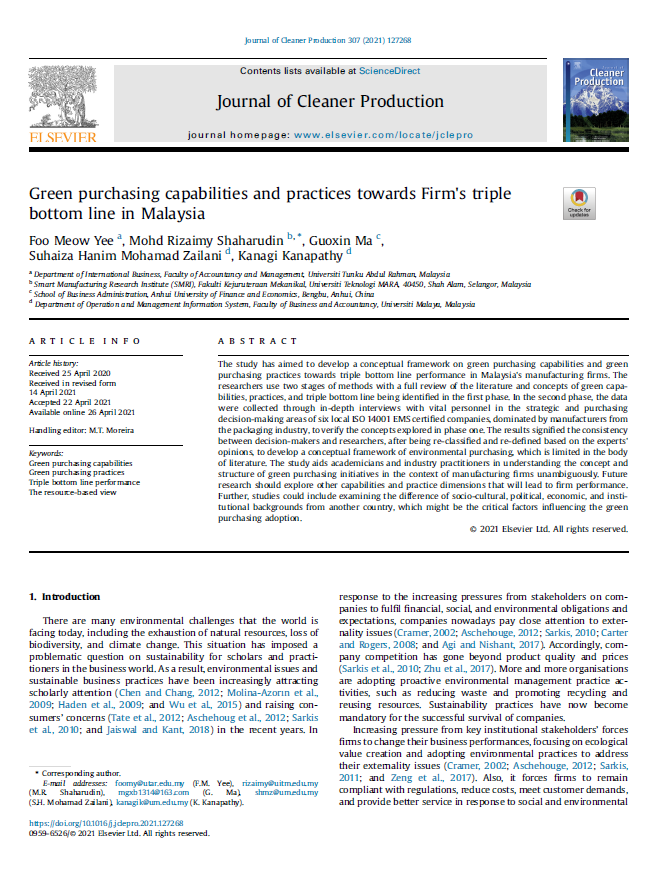

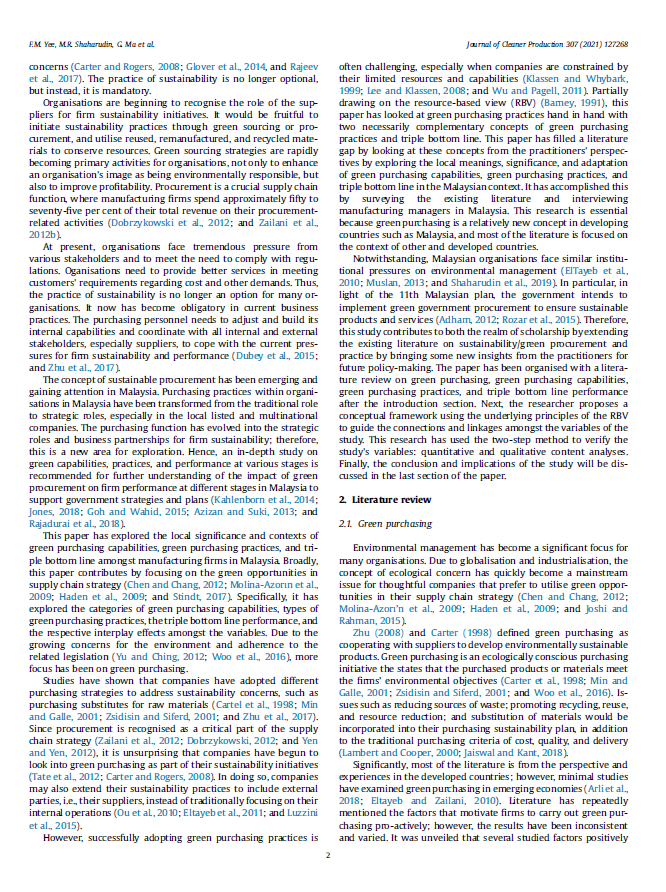

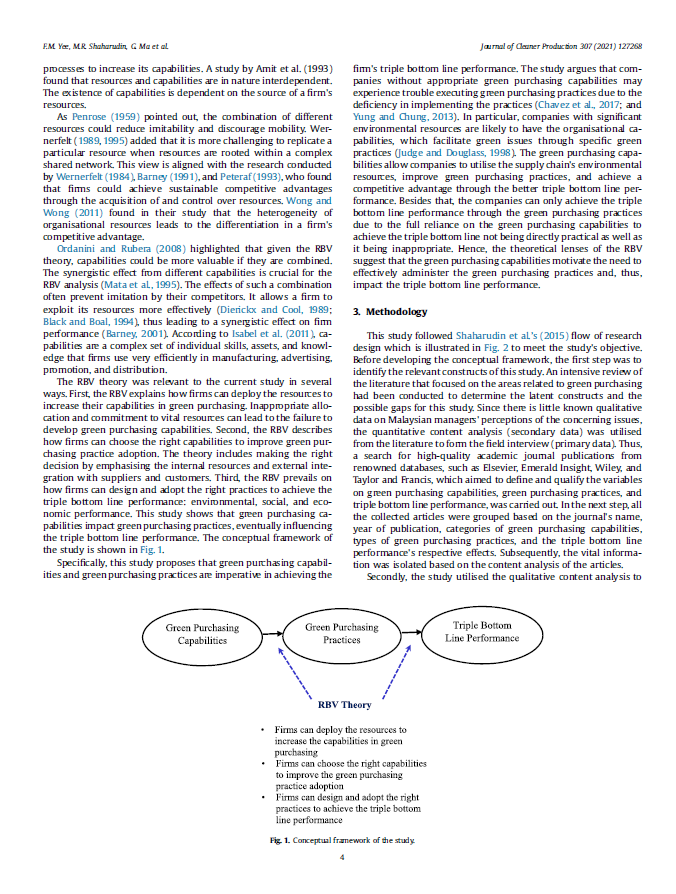

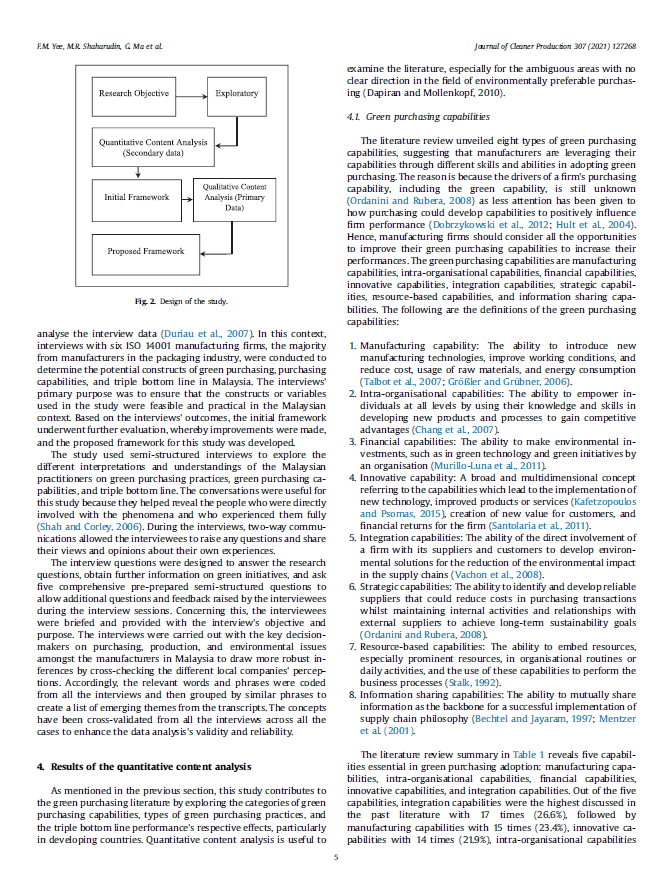

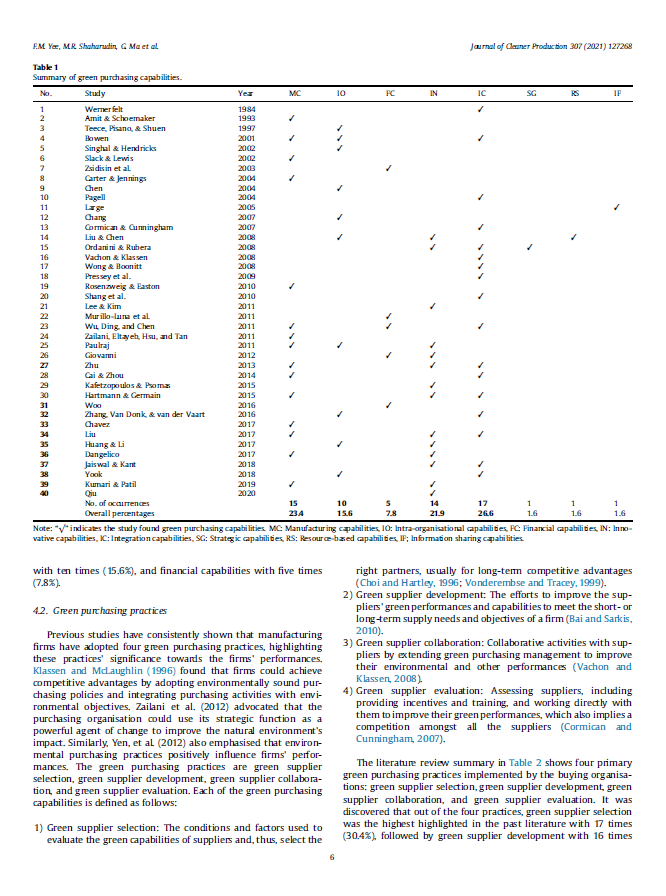

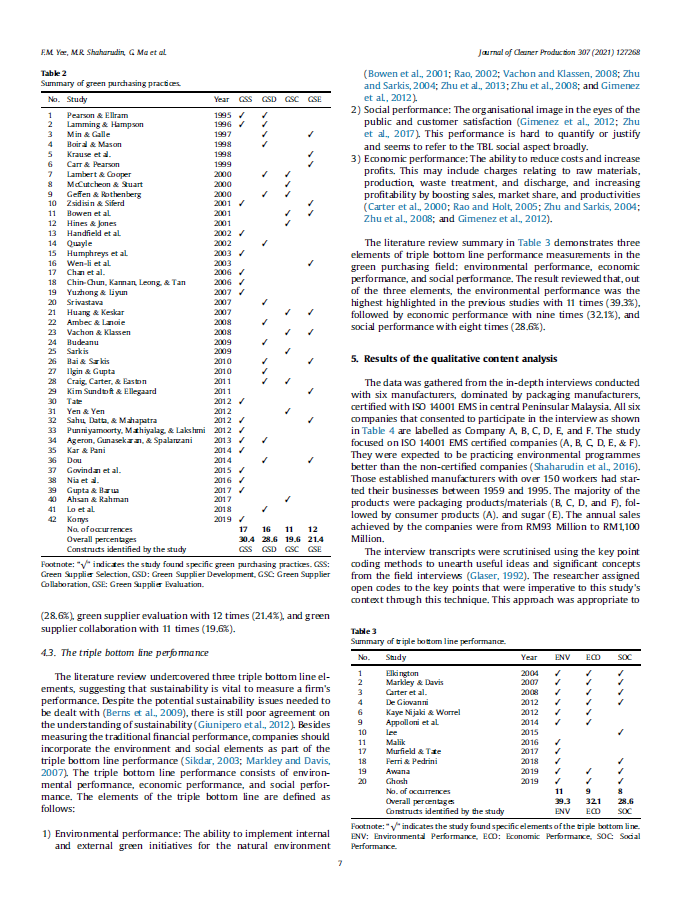

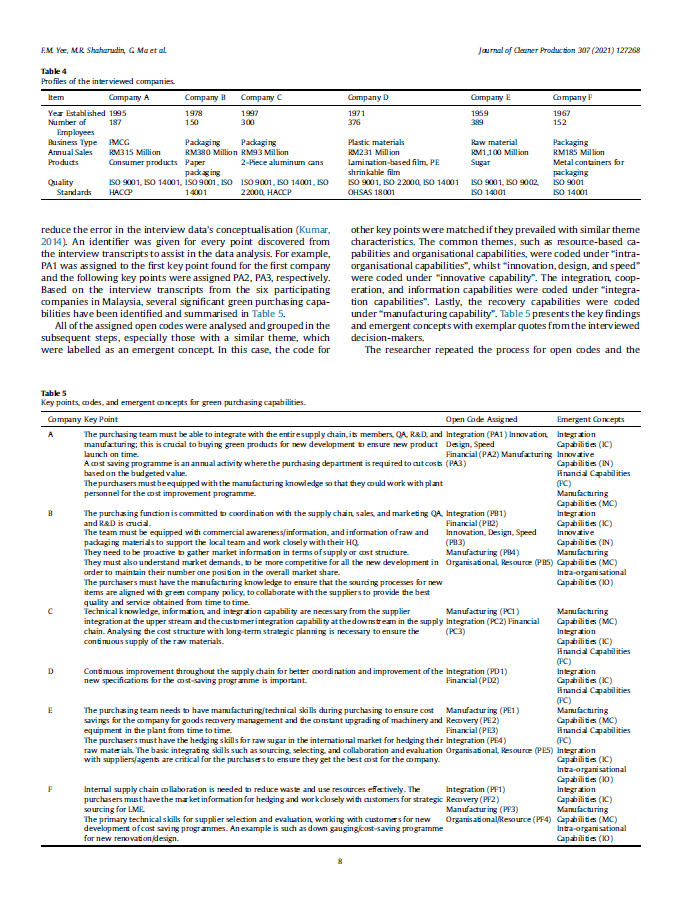

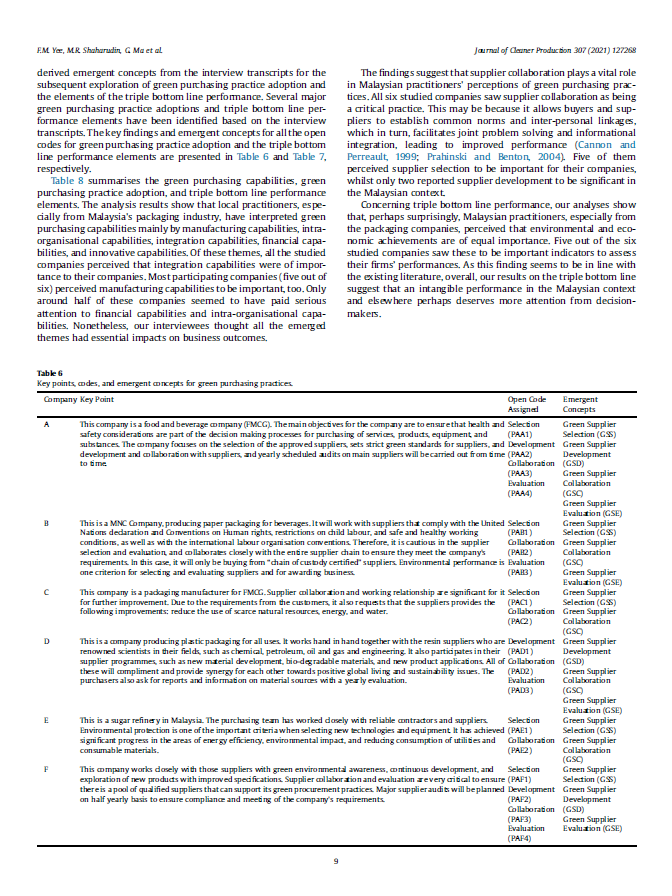

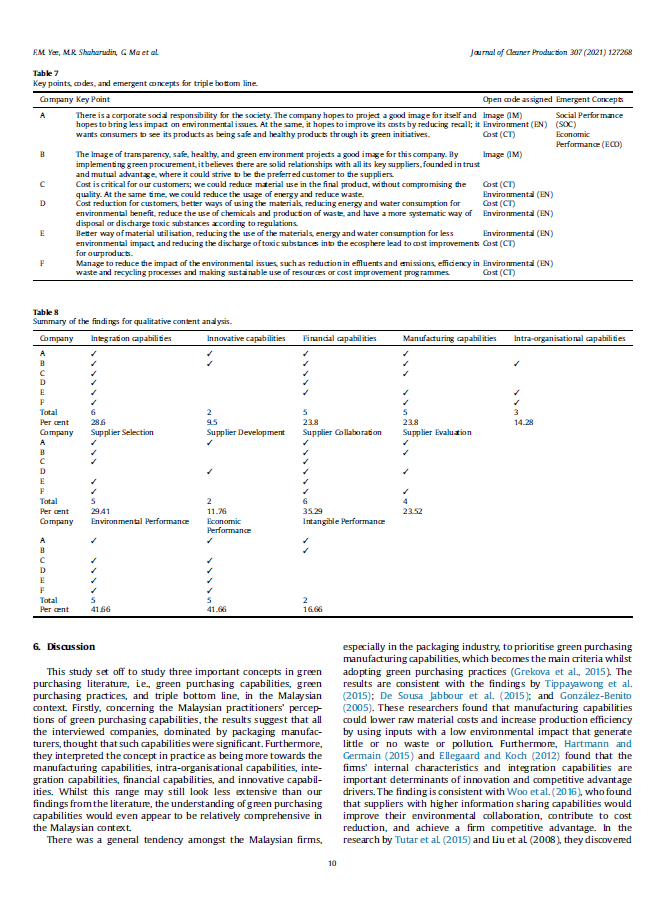

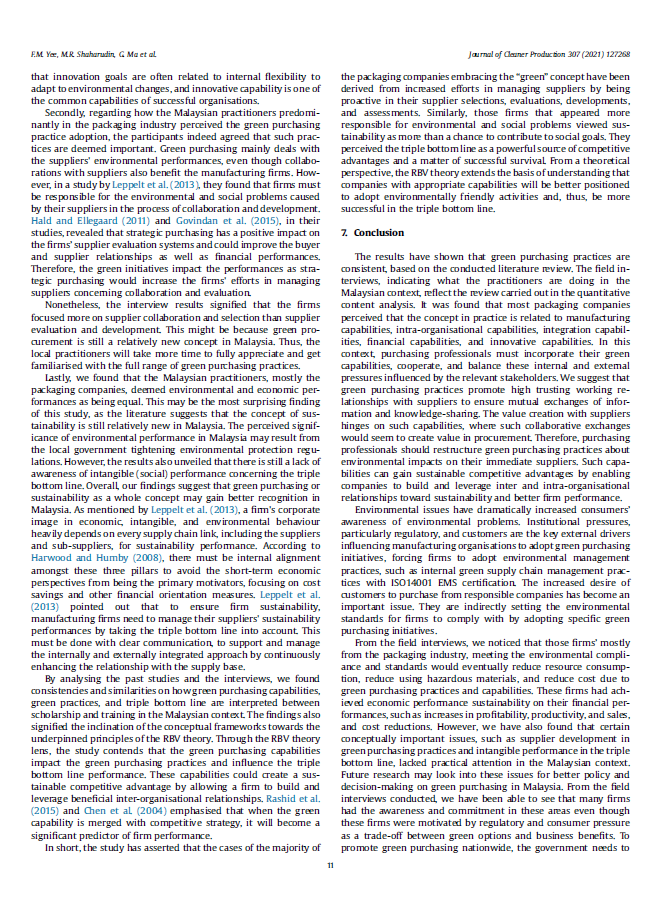

Journal of Ceaner Production 307 (2021) 12/268 Contents lists available at ScienceDirect Journal of Cleaner Production Cleaner Production ELSEVIER journal homepage: www.elsevier.com/locate/jcle pro Check for Green purchasing capabilities and practices towards Firm's triple bottom line in Malaysia Foo Meow Yee , Mohd Rizaimy Shaharudin b.. Guoxin Ma, Suhaiza Hanim Mohamad Zailani", Kanagi Kanapathy Department of International Business, Faculty of Accountancy and Management Universiti Tunku Abdul Rahman, Malaysia Smart Manufacturing Research Institute (SMR). Fakulti Kejuruteraan Mekanikal Universiti Teknologi MARA 40450, Shah Alam, Selangor, Malaysia School of Business Administration, Anhui University of Finance and Economics, Bengbu, Anhui China Department of Operation and Management Information System, Faculty of Business and Accountancy, Universiti Malaya, Malaysia ARTICLE INFO ABSTRACT Article history: Received 25 April 2020 Received in revised form 14 April 2021 Accepted 22 April 2021 Available online 26 April 2021 Handling editor: M.T. Moreira The study has aimed to develop a conceptual framework on green purchasing capabilities and green purchasing practices towards triple bottom line performance in Malaysia's manufacturing firms. The researchers use two stages of methods with a full review of the literature and concepts of green capa- bilities, practices, and triple bottom line being identified in the first phase. In the second phase, the data were collected through in-depth interviews with vital personnel in the strategic and purchasing decision-making areas of six local SO 14001 EMS certified companies, dominated by manufacturers from the packaging industry, to verify the concepts explored in phase one. The results signified the consistency between decision-makers and researchers, after being re-classified and re-defined based on the experts opinions to develop a conceptual framework of environmental purchasing which is limited in the body of literature. The study aids academicians and industry practitioners in understanding the concept and structure of green purchasing initiatives in the context of manufacturing fims unambiguously. Future research should explore other capabilities and practice dimensions that will lead to firm performance. Further, studies could include examining the difference of socio-cultural, political, economic and insti- tutional backgrounds from another country, which might be the critical factors influencing the green purchasing adoption 2021 Elsevier Ltd. All rights reserved. Keywords: Green purchzing capabilities Green purchasing practices Triple bottom line performance The resoure-bzed view 1. Introduction There are many environmental challenges that the world is facing today, including the exhaustion of natural resources, loss of biodiversity, and dimate change. This situation has imposed a problematic question on sustainability for scholars and practi- tioners in the business world. As a result, environmental issues and sustainable business practices have been increasingly attracting scholarly attention (Chen and Chang, 2012; Molina-Azorin et al., 2009: Haden et al., 2009; and Wu et al, 2015) and raising con- sumers' concerns (Tate et al., 2012; Aschehoug et al., 2012; Sarkis et al, 2010; and Jaiswal and Kant, 2018) in the recent years, In response to the increasing pressures from stakeholders on com- panies to fulfil financial, social and environmental obligations and expectations, companies nowadays pay dose attention to exter- nality issues (Cramer, 2002; Aschehouge, 2012; Sarkis, 2010: Carter and Rogers, 2008; and Agi and Nishant, 2017). Accordingly, com- pany competition has gone beyond product quality and prices (Sarkis et al., 2010; Zhu et al., 2017). More and more organisations are adopting proactive environmental management practice - tivities, such as reducing waste and promoting recycling and reusing resources. Sustainability practices have now become mandatory for the successful survival of companies. Increasing pressure from key institutional stakeholders' forces fims to change their business performances, focusing on ecological value creation and adopting environmental practices to address their extemality issues (Cramer, 2002; Aschehouge, 2012; Sarkis, 2011; and Zeng et al., 2017). Also, it forces firms to remain compliant with regulations, reduce costs, meet customer demands, and provide better service in response to social and environmental . Corresponding author. E-mail addresses formyutar.edu.my (F.M Yee) rizaimy@uitmedumy (MR Shaharudin mgxh 1314@163.com (G. Ma) shunzumedumy (SH. Mohamad Zailani) kanagi kum.edu.my (K. Kanapathy). https://doi.org/10.1016 jjdepro2021.127269 0959-6526/ 2021 Elsevier Ltd. All rights reserved. E.MY, MR Shaharudin, G Ma et al concerns (Carter and Rogers, 2008: Glover et al., 2014, and Rajeev et al., 2017). The practice of sustainability is no longer optional, but instead, it is mandatory. Organisations are beginning to recognise the role of the sup- pliers for firm sustainability initiatives. It would be fruitful to initiate sustainability practices through green sourcing or pro- curement, and utilise reused, remanufactured, and recycled mate- rials to conserve resources. Green sourcing strategies are rapidly becoming primary activities for organisations, notonly to enhance an organisation's image as being environmentally responsible, but also to improve profitability. Procurement is a crucial supply chain function, where manufacturing firms spend approximately fifty to seventy-five per cent of their total revenue on their procurement- related activities (Dobrzykowski et al., 2012; and Zailani et al., 2012b) At present, organisations face tremendous pressure from various stakeholders and to meet the need to comply with regu- lations. Oganisations need to provide better services in meeting customers' requirements regarding cost and other demands. Thus, the practice of sustainability is no longer an option for many or- ganisations. It now has become obligatory in current business practices. The purchasing personnel needs to adjust and build its internal capabilities and coordinate with all internal and external stakeholders, especially suppliers, to cope with the current pres- sures for fimm sustainability and performance (Dubey et al., 2015; and Zhu et al., 2017) The concept of sustainable procurement has been emerging and gaining attention in Malaysia. Purchasing practices within organi- sations in Malaysia have been transformed from the traditional role to strategic roles, especially in the local listed and multinational companies. The purchasing function has evolved into the strategic roles and business partnerships for firm sustainability; therefore, this is a new area for exploration. Hence, an in-depth study on green capabilities, practices, and performance at various stages is recommended for further understanding of the impact of green procurement on firm performance at different stages in Malaysia to support government strategies and plans (Kahlenborn et al., 2014; Jones, 2018; Goh and Wahid, 2015: Azizan and Suki, 2013; and Rajadurai et al., 2018) This paper has explored the local significance and contexts of green purchasing capabilities, green purchasing practices, and tri- ple bottom line amongst manufacturing firms in Malaysia Broadly, this paper contributes by focusing on the green opportunities in supply chain strategy (Chen and Chang, 2012; Molina-Azorin et al., 2009; Haden et al., 2009; and Stindt, 2017). Specifically, it has explored the categories of green purchasing capabilities, types of green purchasing practices, the triple bottom line performance, and the respective interplay effects amongst the variables. Due to the growing concerns for the environment and adherence to the related legislation (Yu and Ching. 2012: Woo et al., 2016). more focus has been on green purchasing. Studies have shown that companies have adopted different purchasing strategies to address sustainability concerns, such as purchasing substitutes for raw materials (Cartel et al., 1998; Min and Galle, 2001; Zsidisin and Siferd, 2001; and Zhu et al., 2017). Since procurement is recognised as a critical part of the supply chain strategy (Zailani et al., 2012; Dobrzykowski, 2012; and Yen and Yen, 2012), it is unsurprising that companies have begun to look into green purchasing as part of their sustainability initiatives (Tate et al., 2012; Carter and Rogers, 2008). In doing so, companies may also extend their sustainability practices to include external parties, i.e., their suppliers, instead of traditionally focusing on their internal operations (Ou et al, 2010: Eltayeb et al., 2011; and Luzzini et al., 2015). However, successfully adopting green purchasing practices is Journal of Cleaner Production 207 (2021) 127269 often challenging, especially when companies are constrained by their limited resources and capabilities (Klassen and Whybark, 1999; Lee and Klassen, 2008; and Wu and Pagell, 2011). Partially drawing on the resource-based view (RBV) (Bamey, 1991), this paper has looked at green purchasing practices hand in hand with two necessarily complementary concepts of green purchasing practices and triple bottom line. This paper has filled a literature gap by looking at these concepts from the practitioners' perspec- tives by exploring the local meanings, significance, and adaptation of green purchasing capabilities, green purchasing practices, and triple bottom line in the Malaysian context. It has accomplished this by surveying the existing literature and interviewing manufacturing managers in Malaysia. This research is essential because green purchasing is a relatively new concept in developing countries such as Malaysia, and most of the literature is focused on the context of other and developed countries. Notwithstanding, Malaysian organisations face similar institu- tional pressures on environmental management (ElTayeb et al, 2010; Muslan, 2013; and Shaharudin et al., 2019). In particular, in light of the 11th Malaysian plan, the government intends to implement green government procurement to ensure sustainable products and services (Adham, 2012; Rozar et al., 2015). Therefore, this study contributes to both the realm of scholarship by extending the existing literature on sustainability/green procurement and practice by bringing some new insights from the practitioners for future policy-making. The paper has been organised with a litera- ture review on green purchasing, green purchasing capabilities, green purchasing practices, and triple bottom line performance after the introduction section. Next, the researcher proposes a conceptual framework using the underlying principles of the RBV to guide the connections and linkages amongst the variables of the study. This research has used the two-step method to verify the study's variables: quantitative and qualitative content analyses. Finally, the condusion and implications of the study will be dis- cussed in the last section of the paper, 2 Literature review 2.1. Green purchasing Environmental management has become a significant focus for many organisations. Due to globalisation and industrialisation, the concept of ecological concern has quickly become a mainstream issue for thoughtful companies that prefer to utilise green oppor- tunities in their supply chain strategy (Chen and Chang, 2012; Molina-Azore'n et al., 2009: Haden et al, 2009; and Joshi and Rahman, 2015). Zhu (2008) and Carter (1998) defined green purchasing as cooperating with suppliers to develop environmentally sustainable products. Green purchasing is an ecologically conscious purchasing initiative the states that the purchased products or materials meet the finns' environmental objectives (Carter et al, 1998; Min and Galle, 2001; Zsidisin and Siferd, 2001; and Woo et al., 2016). Is- sues such as reducing sources of waste; promoting recycling, reuse, and resource reduction; and substitution of materials would be incorporated into their purchasing sustainability plan, in addition to the traditional purchasing criteria of cost, quality, and delivery (Lambert and Cooper, 2000; Jaiswal and Kant, 2018). Significantly, most of the literature is from the perspective and experiences in the developed countries; however, minimal studies have examined green purchasing in emerging economies (Arliet al., 2018; Eltayeb and Zailani, 2010). Literature has repeatedly mentioned the factors that motivate firms to carry out green pur- chasing pro-actively; however, the results have been inconsistent and varied. It was unveiled that several studied factors positively 2 F.M Y, MR Shaharudin G Ma et al Journal of Cleaner Production 207 (2021) 127282 influenced green purchasing, such as regulations (Min and Galle, 2001; Preuss, 2001) and customer pressures (Carter and Carter, 1998). However, these two factors were found to have insignifi- cant influence on the green purchasing by Bowen et al. (2001) and Zhu et al. (2007) of the regulations, and the customer pressures by Zhu et al. (2007). In Malaysia, laws and regulations, top manage- ment commitment, and supplier relationships have impacted on the supplier's green purchasing practices (Shaharudin et al., 2018). Nonetheless, the concept of green purchasing is still new in developing countries, with limited empirical studies due to com- panies at large failing to adopt the concept adequately (Ramakrishnan et al., 2015). Hence, the present study has explored the adaptation of green purchasing capabilities, green purchasing practices, and triple bottom line from past studies which were reviewed gathered, and analysed. 22. Green purchasing capabilities Green purchasing capabilities are broadly defined as collecting complex individual skills, assets, and knowledge applied in organisational practices that enable firms to organise their opera- tion activities and resource utilisation to achieve the firms' goals and objectives (Kaya and Erden, 2008; Chen and Fong, 2012). The concept is viewed as the ability of a firm to work dosely with a limited number of suppliers and to integrate internally within their supply-chain members to create a sustainable competitive advan- tage for long-term mutual gains (Lau and Wang, 2009; Ray et al., 2004; and Chen et al., 2004). Although many studies have mentioned the concept, there is a lack of research (Ordanini and Rubera, 2008). Notably, there is little knowledge on how com- panies could develop their purchasing capabilities to influence their performances positively (Dobrzykowski et al., 2012; Hult et al., 2004; and Liu et al., 2017). In this case, most firms' main concerns are whether the purchasing personnel are equipped with green purchasing capabilities with a dear direction that can influ- ence the purchasing practices (Ordanini and Rubera, 2008; Knight et al., 2014). The limited research on green purchasing capabilities shows that environmentally proactive firms may be more willing to deploy their resources and skills to launch green initiatives (Newbert, 2007). Similarly, environmentally active firms may put more effort into developing capabilities for successful green strat- egy implementation (Yang, 2017) and to influence their strategic decisions for competitive outcomes (Gonzlez-Benito, 2005: Yook et al., 2018). Besides that, Wu and Pagell (2011) suggested that successfully implementing green strategies requires possessing and deploying a specific capability, which requires the company to identify, utilise, and assimilate both internal and external resources to facilitate the entire supply chain. 23. Green purchasing practices Whilst there has been a long establishment of the scholarship on supply chain management, the concept of strategic purchasing is now gaining attention from academicians and practitioners (Song et al., 2017). As an emerging stream of literature on strategic pur- chasing green purchasing focuses on cooperating with suppliers to develop environmentally sustainable products (Zhu, 2008: Carter and Carter, 1998; and Kumar and Routroy, 2017). There are two major categories of green purchasing practices studied in the literature: supplier selection and management, and evaluative activities. Supplier selection and management decisions are essential drivers of an organisation's sustainability strategies (Tate, 2012; Sarkis and Dhavale, 2015). Companies usually engage in supplier development programmes, typically involving trust-building, financial investment, relational norm development, and knowl- edge transfer (Bai and Sarkis, 2010: Vachon and Klassen, 2008; and Song et al., 2017). Supplier development programmes can also include more intensive initiatives, such as supplier education, supplier support, or even joint ventures. In general, research on suppliers' environmental collaborations shows promising perfor- mance improvements (Vachon and Klassen, 2008; Geffen and Rothenberg, 2000:Qin et al., 2017; and Awasthi and Kannan, 2016). Evaluative activities generally indude assessing and monitoring suppliers' environmental perfomances. Similar to the collaborative practices with suppliers, research shows that the proactive as- sessments of suppliers on environmental issues can positively impact environmental performance (Zhu and Sarkis, 2007: Rao and Holt, 2005; Gimenez et al., 2012; and Kumar and Routroy, 2017). Similarly, Lee and Klassen (2008) and Govindan et al (2015) sug- gested that supplier evaluation and collaboration produce a better supplier environmental performance. Likewise, Aan et al (2016) and Wen-li et al. (2003) found positive correlations between sup- plier evaluation and purchasing performance. Hence, the organi- sations' strategic purchasing roles and practices require a paradigm shift to a more holistic manner in their environmental and intan- gible dimensions from the conventional association, which only focuses on the financial parameters to gain a sustainable strategic advantage of the firms' sustainability. 2.4. Triple bottom line performance The triple bottom line idea originated from Elkington (1998, 2004), consisting of three components, i.e., the natural environ- ment, society, and the organisation's economic performance. This idea has been further supported by scholars, who suggest that companies should measure their performance not only by evalu- ating the traditional bottom line but also by considering the ecological and social responses to the environmental issues (Markley and Davis, 2007; De Giovanni, 2012; Gimenez et al., 2012; and Longoni and Cagliano, 2018). Furthermore, there is a growing awareness of building sound sustainability principles into their supply chain management as the integration of a company's economic, environmental, and intan- gible objectives to improve the company's long-term performance (Tippayawong et al., 2015; Venkatraman and Nayak, 2015; and Stindt, 2017), Sustainability performance refers to the economic, social, and environmental factors to achieve competitiveness in the market (Ali et al., 2019; Chin et al., 2015). Sustainability perfor- mance requires a high connection between economic, environ- mental and societal performance to gain a competitive advantage (Chin et al, 2015). Due to these reasons, the study has con- ceptualised the three sustainability elements (economic, environ- mental and social sustainability) as the study's triple bottom line performance 2.5. Theoretical foundation The theoretical foundation of the RBV theory grounds this study. The firm's RBV theory specifies that a firm can gain sustainable competitive advantages through organisation-level competencies (Rugman and Verbeke, 2002: Yu et al., 2017). These competencies are the combinations of resources that are rare, non-substitutable, difficult to imitate, and valuable to customers. The RBV signifies that there are two main elements, which are resources and capabilities. Grant (1991) opined that resources could be considered core elements in the RBV to operate a firm's activities. In contrast, the concept of capabilities arises from the fim's ability to create value by utilising existing resources through F.M Y, MR Shaharudin G Ma et al Jamal of Cleaner Production 207 (2021) 127269 processes to increase its capabilities. A study by Amit et al. (1993) fimm's triple bottom line performance. The study argues that com- found that resources and capabilities are in nature interdependent. panies without appropriate green purchasing capabilities may The existence of capabilities is dependent on the source of a firm's experience trouble executing green purchasing practices due to the resources. deficiency in implementing the practices (Chavez et al., 2017; and As Penrose (1959) pointed out, the combination of different Yung and Chung, 2013). In particular, companies with significant resources could reduce imitability and discourage mobility. Wer- environmental resources are likely to have the organisational ca- nerfelt (1989, 1995) added that it is more challenging to replicate a pabilities, which facilitate green issues through specific green particular resource when resources are rooted within a complex practices (Judge and Douglass, 1998). The green purchasing capa- shared network. This view is aligned with the research conducted bilities allow companies to utilise the supply chain's environmental by Wernerfelt (1984), Barney (1991), and Peteraf (1993), who found resources, improve green purchasing practices, and achieve a that fimms could achieve sustainable competitive advantages competitive advantage through the better triple bottom line per- through the acquisition of and control over resources. Wong and formance. Besides that, the companies can only achieve the triple Wong (2011) found in their study that the heterogeneity of bottom line performance through the green purchasing practices organisational resources leads to the differentiation in a firm's due to the full reliance on the green purchasing capabilities to competitive advantage. achieve the triple bottom line not being directly practical as well as Ordanini and Rubera (2008) highlighted that given the RBV it being inappropriate. Hence, the theoretical lenses of the RBV theory, capabilities could be more valuable if they are combined. suggest that the green purchasing capabilities motivate the need to The synergistic effect from different capabilities is crucial for the effectively administer the green purchasing practices and, thus, RBV analysis (Mata et al, 1995). The effects of such a combination impact the triple bottom line performance, often prevent imitation by their competitors. It allows a firm to exploit its resources more effectively (Dierickx and Cool, 1989; 3. Methodology Black and Boal, 1994), thus leading to a synergistic effect on fim performance (Barney, 2001). According to Isabel et al. (2011), ca- This study followed Shaharudin et al's (2015) flow of research pabilities are a complex set of individual skills, assets, and knowl- design which is illustrated in Fig. 2 to meet the study's objective. edge that firms use very efficiently in manufacturing, advertising, Before developing the conceptual framework, the first step was to promotion, and distribution. identify the relevant constructs of this study. An intensive review of The RBV theory was relevant to the current study in several the literature that focused on the areas related to green purchasing ways. First, the RBV explains how firms can deploy the resources to had been conducted to determine the latent constructs and the increase their capabilities in green purchasing. Inappropriate allo- possible gaps for this study. Since there is little known qualitative cation and commitment to vital resources can lead to the failure to data on Malaysian managers' perceptions of the concerning issues, develop green purchasing capabilities. Second, the RBV describes the quantitative content analysis (secondary data) was utilised how firms can choose the right capabilities to improve green pur- from the literature to form the field interview (primary data). Thus, chasing practice adoption. The theory indudes making the right a search for high-quality academic joumal publications from decision by emphasising the internal resources and external inte- renowned databases, such as Elsevier, Emerald Insight, Wiley, and gration with suppliers and customers. Third, the RBV prevails on Taylor and Francis, which aimed to define and qualify the variables how firms can design and adopt the right practices to achieve the on green purchasing capabilities, green purchasing practices, and triple bottom line performance: environmental, social, and eco- triple bottom line performance, was carried out. Inthe next step, all nomic performance. This study shows that green purchasing ca- the collected articles were grouped based on the journal's name, pabilities impact green purchasing practices, eventually influencing year of publication, categories of green purchasing capabilities, the triple bottom line performance. The conceptual framework of types of green purchasing practices, and the triple bottom line the study is shown in Fig. 1. performance's respective effects. Subsequently, the vital informa- Specifically, this study proposes that green purchasing capabil- tion was isolated based on the content analysis of the articles. ities and green purchasing practices are imperative in achieving the Secondly, the study utilised the qualitative content analysis to Green Purchasing Capabilities Green Purchasing Practices Triple Bottom Line Performance RBV Theory Firms can deploy the resources to increase the capabilities in green purchasing Fimms can choose the right capabilities to improve the green purchasing practice adoption Firms can design and adopt the right practices to achieve the triple bottom line performance Fig 1. Conceptual framework of the study F.M Y, MR Shaharudin, G Ma et al Research Objective Exploratory Quantitative Content Analysis (Secondary data) Initial Franework Qualitative Content Analysis (Primary Data) Proposed Framework Fig 2 Design of the study. analyse the interview data (Duriau et al., 2007). In this context, interviews with six ISO 14001 manufacturing firms, the majority from manufacturers in the packaging industry, were conducted to determine the potential constructs of green purchasing. purchasing capabilities, and triple bottom line in Malaysia. The interviews" primary purpose was to ensure that the constructs or variables used in the study were feasible and practical in the Malaysian context. Based on the interviews' outcomes, the initial framework underwent further evaluation, whereby improvements were made, and the proposed framework for this study was developed The study used semi-structured interviews to explore the different interpretations and understandings of the Malaysian practitioners on green purchasing practices, green purchasing ca- pabilities, and triple bottom line. The conversations were useful for this study because they helped reveal the people who were directly involved with the phenomena and who experienced them fully (Shah and Corley, 2006). During the interviews, two-way commu- nications allowed the interviewees to raise any questions and share their views and opinions about their own experiences. The interview questions were designed to answer the research questions, obtain further information on green initiatives, and ask five comprehensive pre-prepared semi-structured questions to allow additional questions and feedback raised by the interviewees during the interview sessions. Concerning this, the interviewees were briefed and provided with the interview's objective and purpose. The interviews were carried out with the key decision- makers on purchasing, production, and environmental issues amongst the manufacturers in Malaysia to draw more robust in- ferences by cross-checking the different local companies' percep- tions. Accordingly, the relevant words and phrases were coded from all the interviews and then grouped by similar phrases to create a list of emerging themes from the transcripts. The concepts have been cross-validated from all the interviews across all the cases to enhance the data analysis's validity and reliability. Journal of Clanner Production 207(2021) 127288 examine the literature, especially for the ambiguous areas with no dear direction in the field of environmentally preferable purchas- ing (Dapiran and Mollenkopf, 2010). 4.1. Green purchasing capabilities The literature review unveiled eight types of green purchasing capabilities, suggesting that manufacturers are leveraging their capabilities through different skills and abilities in adopting green purchasing. The reason is because the drivers of a firm's purchasing capability, including the green capability, is still unknown (Ordanini and Rubera, 2008) as less attention has been given to how purchasing could develop capabilities to positively influence fim performance (Dobrzykowski et al., 2012: Hult et al, 2004). Hence, manufacturing firms should consider all the opportunities to improve their green purchasing capabilities to increase their performances. The green purchasing capabilities are manufacturing capabilities, intra-organisational capabilities, financial capabilities, innovative capabilities, integration capabilities, strategic capabil- ities, resource-based capabilities, and information sharing capa- bilities. The following are the definitions of the green purchasing capabilities: 1. Manufacturing capability: The ability to introduce new manufacturing technologies, improve working conditions, and reduce cost, usage of raw materials, and energy consumption (Talbot et al., 2007: Grler and Grbner, 2006). 2. Intra-organisational capabilities: The ability to empower in- dividuals at all levels by using their knowledge and skills in developing new products and processes to gain competitive advantages (Chang et al, 2007). 3. Financial capabilities: The ability to make environmental in- vestments, such as in green technology and green initiatives by an organisation (Murillo-Luna et al., 2011). 4. Innovative capability: A broad and multidimensional concept referring to the capabilities which lead to the implementation of new technology, improved products or services (Kafetzopoulos and Psomas, 2015), creation of new value for customers, and financial returns for the firm (Santolaria et al, 2011). 5. Integration capabilities: The ability of the direct involvement of a firm with its suppliers and customers to develop environ- mental solutions for the reduction of the environmental impact in the supply chains (Vachon et al., 2008). 6. Strategic capabilities: The ability to identify and develop reliable suppliers that could reduce costs in purchasing transactions whilst maintaining internal activities and relationships with external suppliers to achieve long-term sustainability goals (Ordanini and Rubera, 2008). 7. Resource-based capabilities: The ability to embed resources, especially prominent resources, in organisational routines or daily activities, and the use of these capabilities to perform the business processes (Stalk, 1992). 8. Information sharing capabilities: The ability to mutually share information as the backbone for a successful implementation of supply chain philosophy (Bechtel and Jayaram, 1997; Mentzer et al (2001) The literature review summary in Table 1 reveals five capabil- ities essential in green purchasing adoption: manufacturing capa- bilities, intra-organisational capabilities, financial capabilities, innovative capabilities, and integration capabilities. Out of the five capabilities, integration capabilities were the highest discussed in the past literature with 17 times (26.6%), followed by manufacturing capabilities with 15 times (23.4%), innovative ca- pabilities with 14 times (219%), intra-organisational capabilities 4. Results of the quantitative content analysis As mentioned in the previous section, this study contributes to the green purchasing literature by exploring the categories of green purchasing capabilities, types of green purchasing practices, and the triple bottom line performance's respective effects, particularly in developing countries. Quantitative content analysis is useful to 5 F.M Y, MR Shaharudin, G Ma et al Journal of Cleaner Production 207 (2021) 127268 Table 1 Summary of green purchasing capabilities. No. Study Yer MC 10 FC IN IC SG RS IF 1 Wemer felt 1984 2 Amit & Schoemaker 1993 3 Teece, Pisana, & Shuen 1997 4 Bowen 2001 5 Singhal & Hendricks 2002 6 Slack & Lewis 2002 7 Zsidisin et al 2003 8 Carter & Jennings 2004 9 Chen 2004 10 Pagell 2004 11 Large 2005 12 Chang 2007 13 Cormica & Cummingham 2007 14 Liu & Chen 2008 15 Ordanini & Rubera 2008 16 Vachon & Klassen 2008 17 Wong & Hoonitt 2008 18 Pressey et al. 2009 19 Rosenzweig & Easton 2010 20 Shang et al. 2010 21 Les & Kim 2011 22 Murillo-lana et al 2011 23 Wu Ding, and Chen 2011 24 Zailani, Eltayeh. Hsu and Tan 2011 25 Paulraj 2011 26 Giovanni 2012 27 Zhu 2013 28 Cai & Zhou 2014 Kafetzopoulos & Proma 2015 30 Hartmann & Germain 2015 31 Woo 2016 32 Zhang, Van Donk, & van der Vaart 2016 33 Chavez 2017 34 Liu 2017 1 Huang & Li 2017 36 Dangelica 2017 Jaiswal & Kant 2018 Yook 2018 Kumari & Patil 2019 Qiu 2020 No. of occurrences 1s 10 s 17 1 1 1 Overall percentages 234 15.6 7.8 21.9 26.6 1.6 1.6 1.6 Note: "V"indicates the study found green purchasing capabilities MC Manufacturing capabilities 10: Intra-organisational capabilities. PC: Financial capabilities, IN: Inno- vative capabilities, IC: Integration capabilities. SG: Strategic capabilities, RS: Resource-based capabilities. IP: Information sharing capabilities with ten times ( 15.6), and financial capabilities with five times (78%). 4.2. Green purchasing practices Previous studies have consistently shown that manufacturing firms have adopted four green purchasing practices, highlighting these practices' significance towards the firms' performances. Klassen and McLaughlin (1996) found that firms could achieve competitive advantages by adopting environmentally sound pur- chasing policies and integrating purchasing activities with envi- ronmental objectives. Zailani et al. (2012) advocated that the purchasing organisation could use its strategic function as a powerful agent of change to improve the natural environment's impact. Similarly, Yen, et al. (2012) also emphasised that environ- mental purchasing practices positively influence firms' perfor- mances. The green purchasing practices are green supplier selection, green supplier development, green supplier collabora- tion, and green supplier evaluation. Each of the green purchasing capabilities is defined as follows: 1) Green supplier selection: The conditions and factors used to evaluate the green capabilities of suppliers and thus, select the right partners, usually for long-term competitive advantages (Choi and Hartley, 1996; Vonderembse and Tracey, 1999). 2) Green supplier development: The efforts to improve the sup- pliers' green performances and capabilities to meet the short-or long-term supply needs and objectives of a firm (Bai and Sarkis, 2010). 3) Green supplier collaboration: Collaborative activities with sup- pliers by extending green purchasing management to improve their environmental and other performances (Vachon and Klassen, 2008). 4) Green supplier evaluation: Assessing suppliers, induding providing incentives and training, and working directly with them to improve their green performances, which also implies a competition amongst all the suppliers (Cormican and Cunningham, 2007). The literature review summary in Table 2 shows four primary green purchasing practices implemented by the buying organisa- tions: green supplier selection, green supplier development, green supplier collaboration, and green supplier evaluation. It was discovered that out of the four practices, green supplier selection was the highest highlighted in the past literature with 17 times (30,4%), followed by green supplier development with 16 times 6 F.M Y, MR Shaharudin, G Ma et al Journal of Cleaner Production 207 (2021) 127269 Company D 1971 376 Company E 1959 399 Company F 1967 152 Table 4 Profiles of the interviewed companies. Item Company A Company Company Yes Established 1995 1978 1997 Number of 187 150 300 Employees Business Type PMCG Packaging Padaging Annual Sales RM315 Million RM380 Million RM93 Million Products Consumer products Paper 2-Piece aluminum cans packaging Quality ISO 9001, ISO 14001, ISO 9001, ISO ISO 9001, ISO 14001, ISO Standards HACCP 14001 22000, HACCP Raw material RM1,100 Million Sugar Plastic materials RM231 Million Lamination-based film, PE shrinkable film ISO 9001, ISO 22000, ISO 14001 OHSAS 18001 Packaging RM185 Million Metal containers for packaging ISO 9001 ISO 14001 ISO 9001, ISO 9002 ISO 14001 reduce the error in the interview data's conceptualisation (Kumar, 2014). An identifier was given for every point discovered from the interview transcripts to assist in the data analysis. For example, PA1 was assigned to the first key point found for the first company and the following key points were assigned PAZ, PA3, respectively. Based on the interview transcripts from the six participating companies in Malaysia, several significant green purchasing capa- bilities have been identified and summarised in Table 5. All of the assigned open codes were analysed and grouped in the subsequent steps, especially those with a similar theme, which were labelled as an emergent concept. In this case, the code for other key points were matched if they prevailed with similar theme characteristics. The common themes, such as resource-based ca- pabilities and organisational capabilities, were coded under "intra- organisational capabilities", whilst "innovation, design, and speed" were coded under "innovative capability". The integration, coop- eration, and information capabilities were coded under "integra- tion capabilities. Lastly, the recovery capabilities were coded under "manufacturing capability". Table 5 presents the key findings and emergent concepts with exemplar quotes fmmthe interviewed decision-makers. The researcher repeated the process for open codes and the Tables Key points, andes, and emergent concepts for green purchasing capabilities. Company Key Point Open Code Assigned Emergent Concepts A The purchasing team must be able to integrate with the entiresupply chain, its members. OA, R&D and Integration (PA1) Innovation Integration manufacturing this is crucial to buying green products for new development bereure new product Design. Speed Capabilities (IC) Launch on time. Financial (PA2) Manufacturing Innative A cost saving programme is an annual activity where the purchasing department is required to cut costs (PA3) Capabilities (IN) based on the budgeted value. Financial Capabilities The purchasers must be equipped with the manufacturing knowledge so that they could work with plat (FC) personnel for the most improvement programme Manufacturing Capabilities (MC) B The purchasing function is committed coordination with the supply chain sales and marketing OA, Integration (P91) Integration and R&D is crucial. Financial (P12) Capabilities (IC) The team must be equipped with commercial awareness/information, and information of raw and Innovation, Design, Speed Innovative packaging materials to support the local team and work closely with their HQ (P83) Capabilities (IN) They need to be proactive to gather market information in terms of supply or cost structure. Manufacturing (PM) Manufacturing They must also understand market demands to be more competitive for all the new development in Organisational Resource (PBS) Capabilities (MC) arder to maintain their number one position in the overall market share. Intra-organisational The purchasers must have the manufacturing knowledge to ensure that the sourcing processes for new Capabilities (10) items are aligned with great company policy, to collaborate with the suppliers to provide the best quality and service obtained from time to time. Technical knowledge, information, and integration capability are necessary from the supplier Manufacturing (PCI) Manufacturing integration at the upper stream and the customerintegration capability at the downstream in the supply integration (PC2) Financial Capabilities (MC) chain. Analysing the cost structure with long-term strategic planning is necessary to ensure the (PC3) Integration continuous supply of the raw materials. Capabilities (IC) Financial Capabilities (FC) Continuous improvement throughout the supply chain for better coordination and improvement of the Integration (PD1) Integration new specifications for the cost saving programme is important Financial (PD2) Capabilities (IC) Financial Capabilities (FC) E The purchasing team needs to have manufacturing/technical skills during purchasing to ensure cost Manufacturing (PE1) Manufacturing savings for the company for goods recovery management and the constant upgrading of machinery and Recovery (PE2) Capabilities (MC) equipment in the plant from time to time. Financial (PE) Financial Capabilities The purchasers must have the hedging skills for raw sugar in the international market for hedging their Integration (PS4) (FC) raw materiak. The basic integrating skills such as sourcing selecting and collaboration and evaluation Organisational Resource (PES) Integration with suppliers/agents are critical for the purchasers to ensure they get the best cost for the company. Capabilities (IC) Intra-organisational Capabilities (10) F Internal supply chain collaboration is needed to reduce waste and use resources effectively. The Integration (PF1) Integration purchasers must have the market information for hedging and work closely with customers for strategic Recovery (PF2) Capabilities (IC) sourcing for LME. Manufacturing (PF3) Manufacturing The primary technical skills for supplier selection and evaluation working with customers for new Organisational Resource (PF4) Capabilities (MC) development of cost saving programmes. An example is such as down gauging cost-saving programme Intra-organisational for new renovation design. Capabilities (10) D F.M Ye, MR Shaharudin G Ma et al derived emergent concepts from the interview transcripts for the subsequent exploration of green purchasing practice adoption and the elements of the triple bottom line performance. Several major green purchasing practice adoptions and triple bottom line per- formance elements have been identified based on the interview transcripts. The key findings and emergent concepts for allthe open codes for green purchasing practice adoption and the triple bottom line performance elements are presented in Table 6 and Table 7, respectively. Table 8 summarises the green purchasing capabilities, green purchasing practice adoption, and triple bottom line performance elements. The analysis results show that local practitioners, espe- cially from Malaysia's packaging industry, have interpreted green purchasing capabilities mainly by manufacturing capabilities, intra- organisational capabilities, integration capabilities, financial capa- bilities, and innovative capabilities. Of these themes, all the studied companies perceived that integration capabilities were of impor- tance to their companies. Most participating companies (five out of six) perceived manufacturing capabilities to be important, too. Only around half of these companies seemed to have paid serious attention to financial capabilities and intra-organisational capa- bilities. Nonetheless, our interviewees thought all the emerged themes had essential impacts on business outcomes. Journal of Cenner Production 207 (2021) 127282 The findings suggest that supplier collaboration plays a vital role in Malaysian practitioners' perceptions of green purchasing pra- tices. All six studied companies saw supplier collaboration as being a critical practice. This may be because it allows buyers and sup- pliers to establish common norms and inter-personal linkages, which in turn, facilitates joint problem solving and informational integration, leading to improved performance (Cannon and Perreault, 1999; Prahinski and Benton, 2004). Five of them perceived supplier selection to be important for their companies, whilst only two reported supplier development to be significant in the Malaysian context. Concerning triple bottom line performance, our analyses show that, perhaps surprisingly, Malaysian practitioners, especially from the packaging companies, perceived that environmental and eco- nomic achievements are of equal importance. Five out of the six studied companies saw these to be important indicators to assess their firms' performances. As this finding seems to be in line with the existing literature, overall, our results on the triple bottom line suggest that an intangible performance in the Malaysian context and elsewhere perhaps deserves more attention from decision- makers. A Table 6 Key points, codes, and emergent concepts for green purchasing practices Company Key Point Open Code Emergent Assigned Concepts This company is a food and beverage company (FMCG). The main objectives for the company are to ensure that health and Selection Green Supplier safety considerations are part of the decision making processes for purchasing of services products, equipment and (PAA) Selection (GS) substances. The company focuses on the selection of the approved suppliers, sets strict green standards for suppliers and Development Green Supplier development and collaboration with suppliers, and yearly scheduled audits on main suppliers will becarried out from time (PAA2) Development to time Collaboration (SD) (PAA3) Green Supplier Evaluation Collaboration (PAA) (GSC) Green Supplier Evaluation (GSE) B This is a MNC Company producing paper packaging for beverages. It will work with suppliers that comply with the United Selection Green Supplier Nations dedaration and Conventions on Human rights restrictions on child labour, and safe and healthy working (PAB1) Selection (GS) conditions, as well as with the international labour organisation conventions. Therefore, it is cautious in the supplier Collaboration Green Supplier selection and evaluation, and collaborates closely with the entire supplier chain to ensure they meet the company's (PAR2) Collaboration requirements. In this case, it will only be buying from chain of custody certified suppliers. Environmental performance is Evaluation (GSC ane criterion for selecting and evaluating suppliers and far awarding business (PAR) Green Supplier Evaluation (GSE) This company is a packaging manufacturer for FMCG. Supplier collaboration and working relationship se significant for it Selection Green Supplier for further improvement. Due to the requirements from the customers, it also requests that the suppliers provides the (PACI) Selection (GS) following improvements: reduce the use of scarce natural resources, energy, and water. Collaboration Green Supplier (PAC2) Collaboration (GSC) This is a company producing plastic packaging for all uses. It works hand in hand together with the resin suppliers who are Development Green Supplier renowned scientists in their field, such as chemical petroleum, oil and gas and engineering It ako participates in their (PAD1) Development supplier programmes, such as new material development, biodegradable material, and new product applications. All of Collaboration (GSD) these will compliment and provide synergy for each other towards positive global living and sustainability issues. The (PAD2) Green Supplier purchasers also ask for reports and information on material sources with a yearly evaluation Evaluation Collaboration (PAD) (GSC) Green Supplier Evaluation (GSE) E This is a sugar refinery in Malaysia. The purchasing team has worked dosely with reliable contractors and suppliers Selection Green Supplier Environmental protection is one of the important criteria when selecting new technologies and equipment It has achieved (PAE1) Selection (GS) significant progress in the areas of energy efficiency, environmental impact and reducing consumption of utilities and collaboration Green Supplier consumable materials. (PAE2) Collaboration (GSC F This company works dosely with those suppliers with green environmental awareness, continuous development, and Selection Green Supplier exploration of new products with improved specifications Supplier collabortion and evaluation every critical to ensure (PAF1) Selection (SS) there is a pool of qualified suppliers that can support its green procurement practices Major supplier audits will be planned Development Green Supplier on half yearly basis to ensure compliance and meeting of the company's requirements (PAF2) Development Collaboration (GSD) (PAF3) Green Supplier Evaluation Evaluation (GSE) (PAF) D 9 F.M Y, MR Shaharudin, G Ma et al Journal of Czer Production 207 (2021) 127269 Table 7 Key points, codes, and emergent concepts for triple bottom line. Company Key Point Open code assigned Imergent Concepts A There is a corporate social responsibility for the society. The company hopes to project a good image for itself and Image (IM) Social Performance hopes to bring less impact on environmental issues. At the same, it hopes to improve its costs by reducing recall; it Environment (EN) (SOC) wants consumers to see its products as being safe and healthy products through its green initiatives. Cost (CT) Economic Performance (ECO) B The Image of transparency, safe, healthy and green environment projects a good image for this company. By Image (M) implementing green procurement, it believes there are solid relationships with all its key suppliers, founded in trust and mutual advantage, where it could strive to be the preferred customer to the suppliers Cast is critical for our customers, we could reduce material use in the final product, without compromising the Cost (CT) quality. At the same time, we could reduce the usage of energy and reduce waste. Environmental (EN) Cast reduction for customers, better ways of using the materiak, reducing energy and water consumption for Cost (CT) environmental benefit, reduce the use of chemicals and production of waste and have a more systematic way of Environmental (EN) disposal or discharge toxic substances scording to regulations E Better way of material utilisation, reducing the use of the materials, energy and water consumption for less Environmental (EN) environmental impact and reducing the discharge of tocic substances into the ecosphere lead to cost improvements Cost (CT) for ourproducts. F Manage to reduce the impact of the environmental issues, such as reduction in effluents and emissions, efficiency in Environmental (EN) waste and recycling processes and making sustainable use of resources or cost improvement programmes Cost(CT) D Financial capabilities Manufacturing capabilities Intra-organisational capabilities 5 23.8 Supplier Collaboration 3 14.28 23.8 Supplier Ilvaluation Table 8 Summary of the findings for qualitative content analysis Company Integration capabilities Innovative capabilities A B C D E F Total 6 2 Per cent 286 95 Company Supplier Selection Supplier Development A B C D E F Total 5 2 Per cent 29.41 11.36 Company Environmental Performance Economic Performance A B D E F Total 5 5 Per cent 4166 41.66 23.52 35.29 Intangible Performance 19.66 6. Discussion This study set off to study three important concepts in green purchasing literature, ie, green purchasing capabilities, green purchasing practices, and triple bottom line, in the Malaysian context. Firstly, concerning the Malaysian practitioners' percep- tions of green purchasing capabilities, the results suggest that all the interviewed companies, dominated by packaging manufac- turers, thought that such capabilities were significant. Furthermore, they interpreted the concept in practice as being more towards the manufacturing capabilities, intra-organisational capabilities, inte- gration capabilities, financial capabilities, and innovative capabil- ities. Whilst this range may still look less extensive than our findings from the literature, the understanding of green purchasing capabilities would even appear to be relatively comprehensive in the Malaysian context. There was a general tendency amongst the Malaysian firms, especially in the packaging industry, to prioritise green purchasing manufacturing capabilities, which becomes the main criteria whilst adopting green purchasing practices (Grekova et al., 2015). The results are consistent with the findings by Tippayawong et al. (2015): De Sousa Jabbour et al. (2015): and Gonzlez-Benito (2005). These researchers found that manufacturing capabilities could lower raw material costs and increase production efficiency by using inputs with a low environmental impact that generate little or no waste or pollution Furthermore, Hartmann and Germain (2015) and Ellegaard and Koch (2012) found that the firms internal characteristics and integration capabilities are important determinants of innovation and competitive advantage drivers. The finding is consistent with Woo et al. (2016), who found that suppliers with higher information sharing capabilities would improve their environmental collaboration, contribute to cost reduction, and achieve a firm competitive advantage. In the research by Tutar et al (2015) and Liu et al (2008), they discovered 10 F.M Y, MR Shaharudin, G Ma et al Journal of Cleaner Production 207 (2021) 127268 the packaging companies embracing the "green" concept have been derived from increased efforts in managing suppliers by being proactive in their supplier selections, evaluations, developments, and assessments. Similarly, those firms that appeared more responsible for environmental and social problems viewed sus- tainability as more than a chance to contribute to social goals. They perceived the triple bottom line as a powerful source of competitive advantages and a matter of successful survival From a theoretical perspective, the RBV theory extends the basis of understanding that companies with appropriate capabilities will be better positioned to adopt environmentally friendly activities and, thus, be more successful in the triple bottom line. 7. Conclusion that innovation goals are often related to internal flexibility to adapt to environmental changes, and innovative capability is one of the common capabilities of successful organisations. Secondly, regarding how the Malaysian practitioners predomi- nantly in the packaging industry perceived the green purchasing practice adoption, the participants indeed agreed that such prac- tices are deemed important. Green purchasing mainly deals with the suppliers' environmental performances, even though collabo- rations with suppliers also benefit the manufacturing firms. How- ever, in a study by Leppelt et al. (2013), they found that firms must be responsible for the environmental and social problems caused by their suppliers in the process of collaboration and development. Hald and Ellegaard (2011) and Govindan et al. (2015), in their studies, revealed that strategic purchasing has a positive impact on the firms' supplier evaluation systems and could improve the buyer and supplier relationships as well as financial performances. Therefore, the green initiatives impact the performances as stra- tegic purchasing would increase the firms' efforts in managing suppliers conceming collaboration and evaluation Nonetheless, the interview results signified that the firms focused more on supplier collaboration and selection than supplier evaluation and development. This might be because green pro- curement is still a relatively new concept in Malaysia. Thus, the local practitioners will take more time to fully appreciate and get familiarised with the full range of green purchasing practices. Lastly, we found that the Malaysian practitioners, mostly the packaging companies, deemed environmental and economic per- formances as being equal. This may be the most surprising finding of this study, as the literature suggests that the concept of sus- tainability is still relatively new in Malaysia. The perceived signif- icance of environmental performance in Malaysia may result from the local government tightening environmental protection regu- lations. However, the results also unveiled that there is still a lack of awareness of intangible (social) performance concerning the triple bottom line. Overall, our findings suggest that green purchasing or sustainability as a whole concept may gain better recognition in Malaysia. As mentioned by Leppelt et al. (2013), a fim's corporate image in economic, intangible, and environmental behaviour heavily depends on every supply chain link, including the suppliers and sub-suppliers, for sustainability perfomance. According to Harwood and Humby (2008), there must be internal alignment amongst these three pillars to avoid the short-term economic perspectives from being the primary motivators, focusing on cost savings and other financial orientation measures. Leppelt et al. (2013) pointed out that to ensure firm sustainability, manufacturing firms need to manage their suppliers' sustainability performances by taking the triple bottom line into account. This must be done with clear communication, to support and manage the internally and externally integrated approach by continuously enhancing the relationship with the supply base. By analysing the past studies and the interviews, we found consistencies and similarities on howgreen purchasing capabilities, green practices, and triple bottom line are interpreted between scholarship and training in the Malaysian context. The findings also signified the indination of the conceptual frameworks towards the underpinned principles of the RBV theory. Through the RBV theory lens, the study contends that the green purchasing capabilities impact the green purchasing practices and influence the triple bottom line performance. These capabilities could create a sus- tainable competitive advantage by allowing a firm to build and leverage beneficial inter-organisational relationships. Rashid et al. (2015) and Chen et al (2004) emphasised that when the green capability is merged with competitive strategy, it will become a significant predictor of firm performance. In short, the study has asserted that the cases of the majority of The results have shown that green purchasing practices are consistent, based on the conducted literature review. The field in- terviews, indicating what the practitioners are doing in the Malaysian context, reflect the review carried out in the quantitative content analysis. It was found that most packaging companies perceived that the concept in practice is related to manufacturing capabilities, intra-organisational capabilities, integration capabil- ities, financial capabilities, and innovative capabilities. In this context, purchasing professionals must incorporate their green capabilities, cooperate, and balance these internal and extemal pressures influenced by the relevant stakeholders. We suggest that green purchasing practices promote high trusting working re- lationships with suppliers to ensure mutual exchanges of infor- mation and knowledge-sharing. The value creation with suppliers hinges on such capabilities, where such collaborative exchanges would seem to create value in procurement. Therefore, purchasing professionals should restructure green purchasing practices about environmental impacts on their immediate suppliers. Such capa- bilities can gain sustainable competitive advantages by enabling companies to build and leverage inter and intra-organisational relationships toward sustainability and better firm performance. Environmental issues have dramatically increased consumers' awareness of environmental problems. Institutional pressures, particularly regulatory, and customers are the key external drivers influencing manufacturing organisations to adopt green purchasing initiatives, forcing firms to adopt environmental management practices, such as internal green supply chain management prac- tices with ISO 14001 EMS certification The increased desire of customers to purchase from responsible companies has become an important issue. They are indirectly setting the environmental standards for firms to comply with by adopting specific green purchasing initiatives. From the field interviews, we noticed that those firms' mostly from the packaging industry, meeting the environmental compli- ance and standards would eventually reduce resource consump- tion, reduce using hazardous materials, and reduce cost due to green purchasing practices and capabilities. These firms had ach- ieved economic perfomance sustainability on their financial per- formances, such as increases in profitability productivity, and sales, and cost reductions. However, we have also found that certain conceptually important issues, such as supplier development in green purchasing practices and intangible performance in the triple bottom line, lacked practical attention in the Malaysian context. Future research may look into these issues for better policy and decision-making on green purchasing in Malaysia. From the field interviews conducted, we have been able to see that many firms had the awareness and commitment in these areas even though these firms were motivated by regulatory and consumer pressure as a trade-off between green options and business benefits. To promote green purchasing nationwide, the government needs to 11 F.M Ye, MR Shaharudin G Ma et al Journal of Cerner Production 207 (2021) 127262 Credit authorship contribution statement Foo Meow Yee: Data curation, Investigation, Writing - original draft, Mohd Rizaimy Shaharudin: Conceptualization, Writing review & editing. Guaxin Ma: Validation Visualization. Suhaiza Hanim Mohamad Zailani: Project administration, Resources, Su- pervision. Kanagi Kanapathy: Formal analysis, Methodology. Dedaration of competing interest The authors dedare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper, cascade down to the private sectors, leading to a sustainable development policy goal in Malaysia a