Answered step by step

Verified Expert Solution

Question

1 Approved Answer

As a process engineer you are hired to design a chemical plant to produce 8 0 , 0 0 metric tons per annum of ethylbenzene

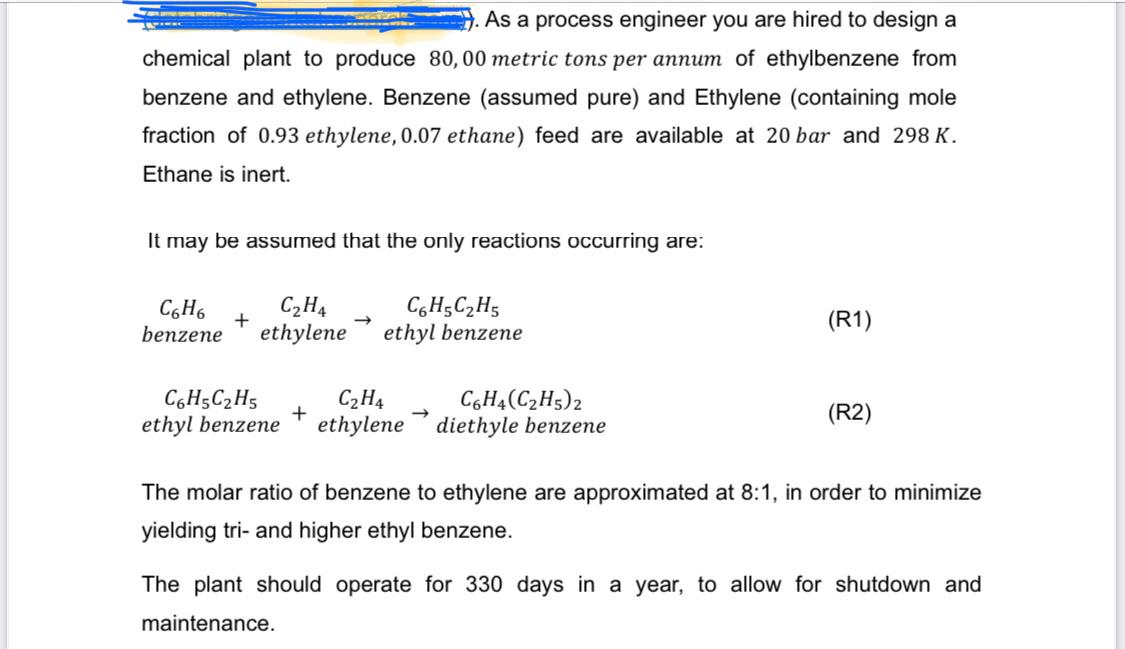

As a process engineer you are hired to design a

chemical plant to produce metric tons per annum of ethylbenzene from

benzene and ethylene. Benzene assumed pure and Ethylene containing mole

fraction of ethylene, ethane feed are available at and

Ethane is inert.

It may be assumed that the only reactions occurring are:

The molar ratio of benzene to ethylene are approximated at : in order to minimize

yielding tri and higher ethyl benzene.

The plant should operate for days in a year, to allow for shutdown and

maintenance. Executive summary

Table of Contents

Design Basis

Literature review

Process Simulation

Include process flow diagram from COCO in GREEN colour to show

you have run it

Process Description

Process Flow Diagram

Include process flow diagram with all equipment labelled tag

namenumber and stream namesnumbers and table of mass and

energy balance. Please use Microschs Visio or other software to draw

the process flow diagram. Not COCO process flow diagram.

Equipment list

Conclusions

References

Appendices if any The economics information:

Useful information:

tableUtility costs.,US DollarsLow Pressure Steam kPa saturated$GJMedium Pressure Steam kPa saturated$GJHigh Pressure Steam kPa saturated$GNatural Gas kPa,deg C$GJElectricity$kWhBoiler Feed Water at :kPa,deg C$kgCooling Water kPa: and :deg CReturn pressure kPa,Return temperature is no more than deg C above the inlet,temperature$GJRefrigerated Water available at kPa and :deg CReturn pressure kPa,Return temperature in no higher than deg C$GJLowtemperature Refrigerant, available at deg C$GJVerylowtemperature Refrigerant, available at deg C$GJDesign basis.

Literature Survey.

Please remember to properly use referencing in your report. Use Harvard

referencing.

Process Simulation COCO Include the green PFD from COCO.

Remember, the purpose of the simulator is to assist you in doing your work, not

to do the work for you. Remember to include a discussion of the manual

calculations you performed in addition to a description of your simulation and

thermodynamic property method and models used. The simulation report

generated by the simulation package can be included in the appendix.

Process Description.

Process Flow diagram with a table containing mass and energy balances: the

flowrates, compositions, temperature, and pressures of all the process streams

not needed for the utilities like steam and cooling water All the process

equipment should be indicated on this flow diagram.

Equipment list please DONT USE GPTCHAT ND PLEASE IT IN WORD FORM SHOW ALL THE CALCULATIONS AND GRAPHS I ALSO INCLUDE THE PICTURE WHERE YOU GET ALL THE INFORMATIONS THANKS As a process engineer you are hired to design a

chemical plant to produce metric tons per annum of ethylbenzene from

benzene and ethylene. Benzene assumed pure and Ethylene containing mole

fraction of ethylene, ethane feed are available at and

Ethane is inert.

It may be assumed that the only reactions occurring are:

The molar ratio of benzene to ethylene are approximated at : in order to minimize

yielding tri and higher ethyl benzene.

The plant should operate for days in a year, to allow for shutdown and

maintenance.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started