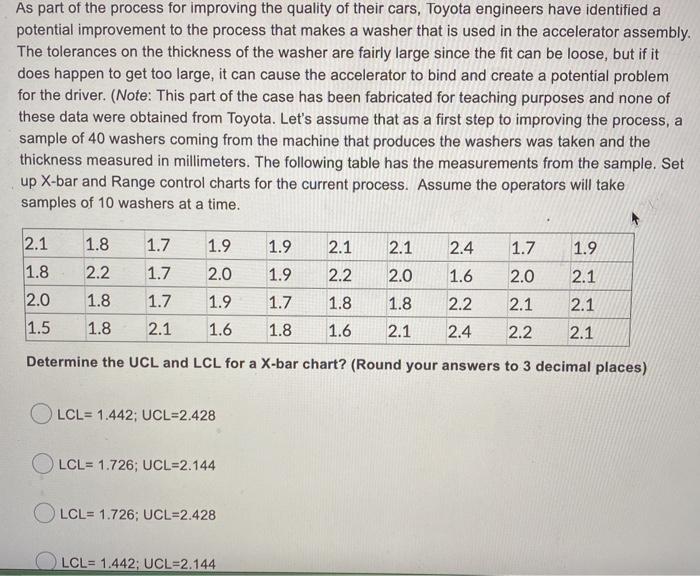

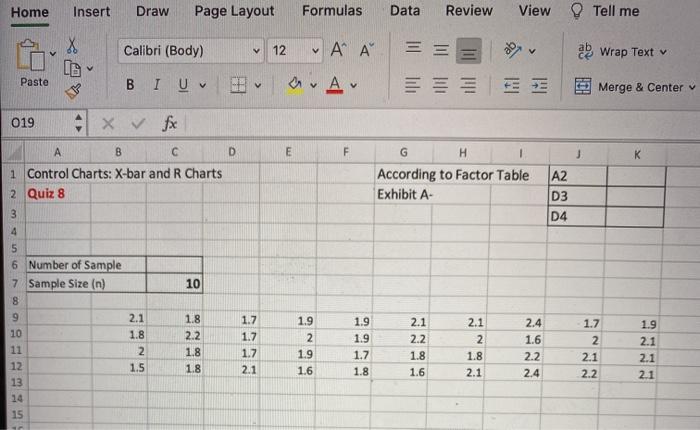

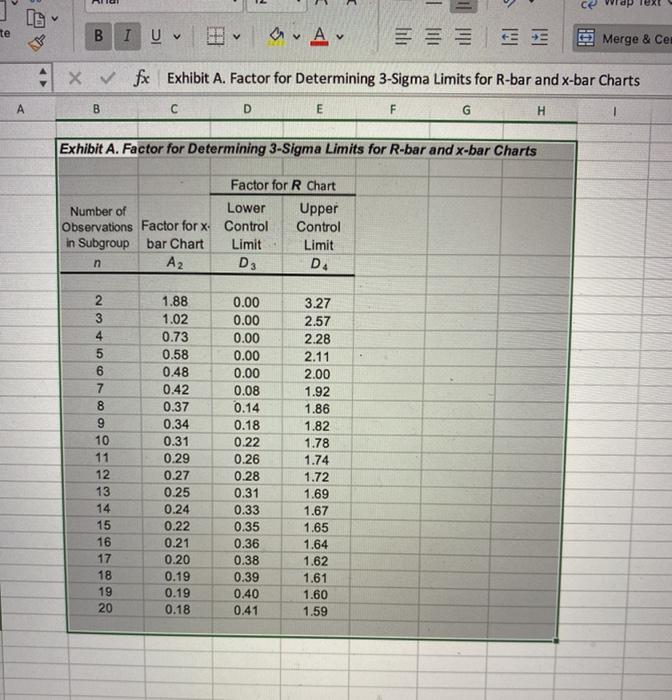

As part of the process for improving the quality of their cars, Toyota engineers have identified a potential improvement to the process that makes a washer that is used in the accelerator assembly. The tolerances on the thickness of the washer are fairly large since the fit can be loose, but if it does happen to get too large, it can cause the accelerator to bind and create a potential problem for the driver. (Note: This part of the case has been fabricated for teaching purposes and none of these data were obtained from Toyota. Let's assume that as a first step to improving the process, a sample of 40 washers coming from the machine that produces the washers was taken and the thickness measured in millimeters. The following table has the measurements from the sample. Set up X-bar and Range control charts for the current process. Assume the operators will take samples of 10 washers at a time. * 4 2.1 1.8 1.7 1.9 1.9 2.1 2.1 1.7 1.9 2.4 1.6 1.8 2.2 1.7 2.2 2.0 2.0 2.1 2.0 1.9 1.8 1.7 1.9 1.7 1.8 1.8 1.8 2.1 2.0 1.5 2.1 2.2 2.4 1.8 2.1 1.6 1.6 2.1 2.2 2.1 Determine the UCL and LCL for a X-bar chart? (Round your answers to 3 decimal places) LCL= 1.442; UCL=2.428 OLCL= 1.726; UCL=2.144 OLCL= 1.726; UCL=2.428 LCL= 1.442; UCL=2.144 Home Insert Draw Page Layout Formulas Data Review View Tell me X Calibri (Body) v 12 ' == ab Wrap Text Paste BIU v a. Av Merge & Center 019 x B D E F G J K A2 1 Control Charts: X-bar and R Charts 2 Quiz 8 3 According to Factor Table Exhibit A- D3 D4 4 10 2.1 5 6 Number of Sample 7 Sample Size (n) 8 9 10 11 12 13 14 15 1.8 1.8 2.2 1.8 1.8 1.7 1.7 1.7 2.1 2 1.5 1.9 2 1.9 1.6 1.9 1.9 1.7 1.8 2.1 2.2 1.8 1.6 2.1 2 1.8 2.1 2.4 1.6 2.2 2.4 1.7 2 2.1 2.2 1.9 2.1 2.1 2.1 ce te B B I U V a. Av SE Merge & Ce x fx Exhibit A. Factor for Determining 3-Sigma Limits for R-bar and x-bar Charts A B C D E F G H 1 Exhibit A. Factor for Determining 3-Sigma Limits for R-bar and x-bar Charts Factor for R Chart Number of Lower Upper Observations Factor for X Control Control in Subgroup bar Chart Limit Limit n A2 D3 D 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 1.88 1.02 0.73 0.58 0.48 0.42 0.37 0.34 0.31 0.29 0.27 0.25 0.24 0.22 0.21 0.20 0.19 0.19 0.18 0.00 0.00 0.00 0.00 0.00 0.08 0.14 0.18 0.22 0.26 0.28 0.31 0.33 0.35 0.36 0.38 0.39 0.40 0.41 3.27 2.57 2.28 2.11 2.00 1.92 1.86 1.82 1.78 1.74 1.72 1.69 1.67 1.65 1.64 1.62 1.61 1.60 1.59