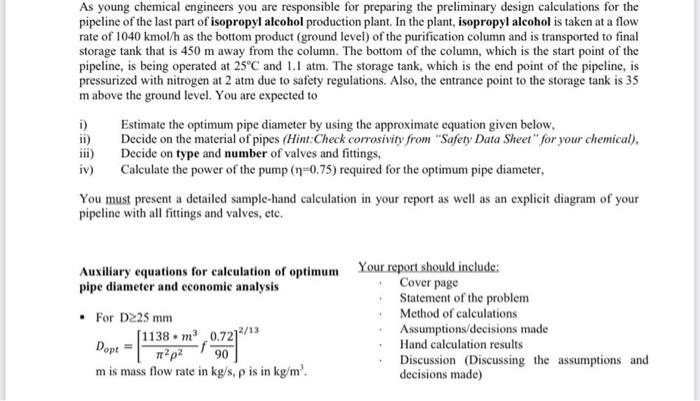

As young chemical engineers you are responsible for preparing the preliminary design calculations for the pipeline of the last part of isopropyl alcohol production plant. In the plant, isopropyl alcohol is taken at a flow rate of 1040kmol/h as the bottom product (ground level) of the purification column and is transported to final storage tank that is 450m away from the column. The bottom of the column, which is the start point of the pipeline, is being operated at 25C and 1.1atm. The storage tank, which is the end point of the pipeline, is pressurized with nitrogen at 2atm due to safety regulations. Also, the entrance point to the storage tank is 35 m above the ground level. You are expected to i) Estimate the optimum pipe diameter by using the approximate equation given below, ii) Decide on the material of pipes (Hint: Check corrosivity from "Safety Data Sheet" for your chemical), iii) Decide on type and number of valves and fittings, iv) Calculate the power of the pump ( =0.75) required for the optimum pipe diameter, You must present a detailed sample-hand calculation in your report as well as an explicit diagram of your pipeline with all fittings and valves, etc. Auxiliary equations for calculation of optimum pipe diameter and economic analysis - For D25mm Dopt=[221138m3f900.72]2/13 m is mass flow rate in kg/s, is in kg/m3. Your report should include: Cover page Statement of the problem Method of calculations Assumptions/decisions made Hand calculation results Discussion (Discussing the assumptions and decisions made) As young chemical engineers you are responsible for preparing the preliminary design calculations for the pipeline of the last part of isopropyl alcohol production plant. In the plant, isopropyl alcohol is taken at a flow rate of 1040kmol/h as the bottom product (ground level) of the purification column and is transported to final storage tank that is 450m away from the column. The bottom of the column, which is the start point of the pipeline, is being operated at 25C and 1.1atm. The storage tank, which is the end point of the pipeline, is pressurized with nitrogen at 2atm due to safety regulations. Also, the entrance point to the storage tank is 35 m above the ground level. You are expected to i) Estimate the optimum pipe diameter by using the approximate equation given below, ii) Decide on the material of pipes (Hint: Check corrosivity from "Safety Data Sheet" for your chemical), iii) Decide on type and number of valves and fittings, iv) Calculate the power of the pump ( =0.75) required for the optimum pipe diameter, You must present a detailed sample-hand calculation in your report as well as an explicit diagram of your pipeline with all fittings and valves, etc. Auxiliary equations for calculation of optimum pipe diameter and economic analysis - For D25mm Dopt=[221138m3f900.72]2/13 m is mass flow rate in kg/s, is in kg/m3. Your report should include: Cover page Statement of the problem Method of calculations Assumptions/decisions made Hand calculation results Discussion (Discussing the assumptions and decisions made)