Question: Assignment: This assignment provides students with the opportunity to analyze fragmented information to build a total cost model for a die casting part. Your perspective

Assignment: This assignment provides students with the opportunity to analyze fragmented information to build a total cost model for a die casting part. Your perspective is as a new buyer of castings.

Requirements

-

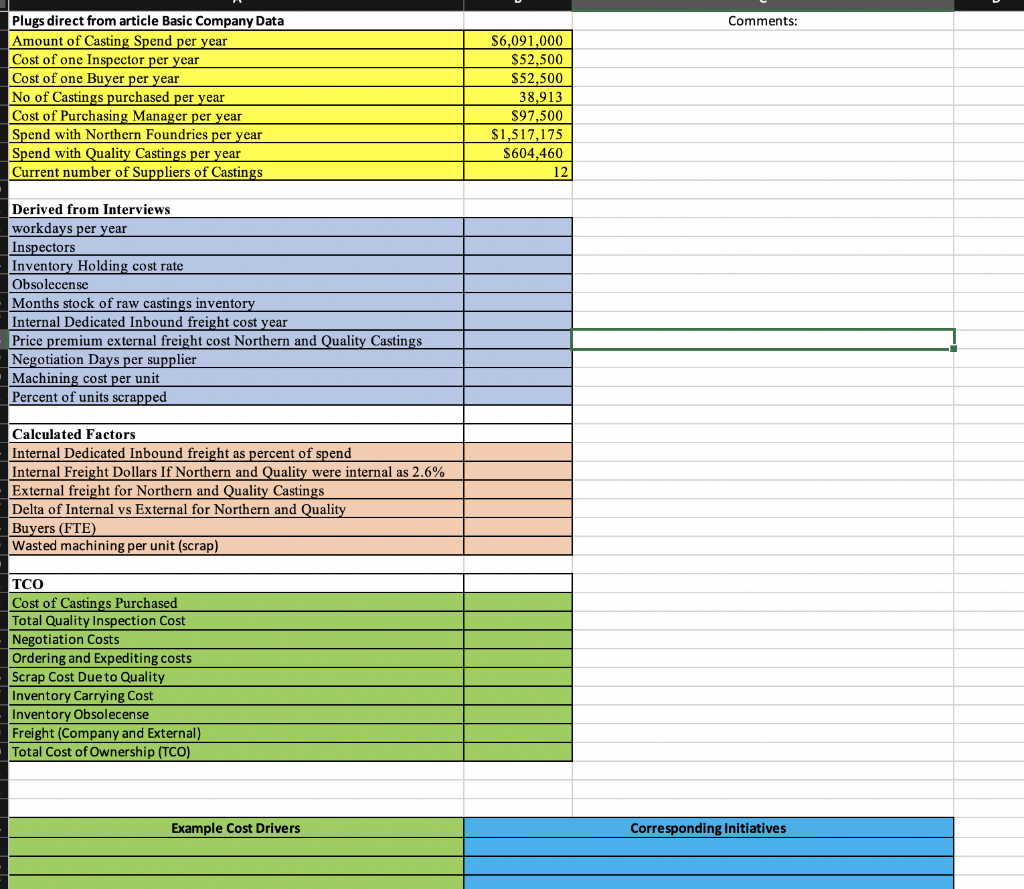

Use the provided Excel template provided in D2L/Team Assignments/TA3 for this exercise.

-

From the interview transcripts provided below use the provided excel template to produce a model which represents the total known acquisition costs incurred by the Spartan Pump Company for the purchase of castings. Calculate each of the following cost elements as subtotals and then sum for total cost:

-

Cost of Castings Purchased

-

Quality inspection cost

-

Negotiation cost

-

Ordering and expediting cost

-

Scrap due to quality failure

-

Inventory carrying cost

-

Inventory obsolescence cost

-

Freight (company and External)

-

For each element of the total cost model generated in 1 above, identify what you believe is the most important cost driver.

-

For the cost drivers you identified, think of a strategic option that Spartan Pumps could manage to impact each of your identified cost drivers.

-

Start the assignment by inputting the basic company data found on the last page of the case.

-

Read the entire case and extract all the case information that impacts cost so these data are visible and can be used in your calculations of the cost elements.

-

Consider how to build each cost calculation. How to turn case information into a useful cost analysis. Teams will need to critically examine the case information and build calculations for each cost element in 1 a-h.

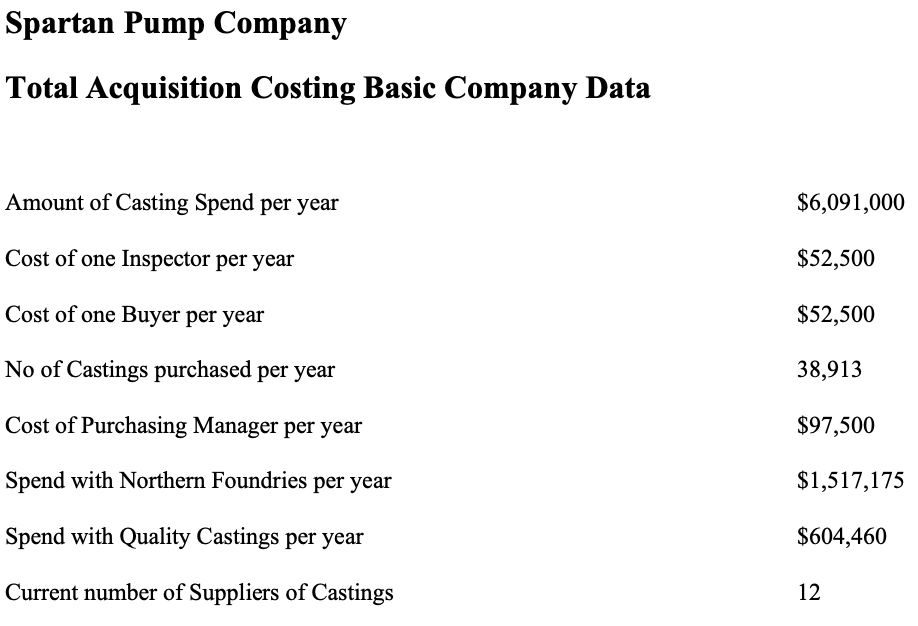

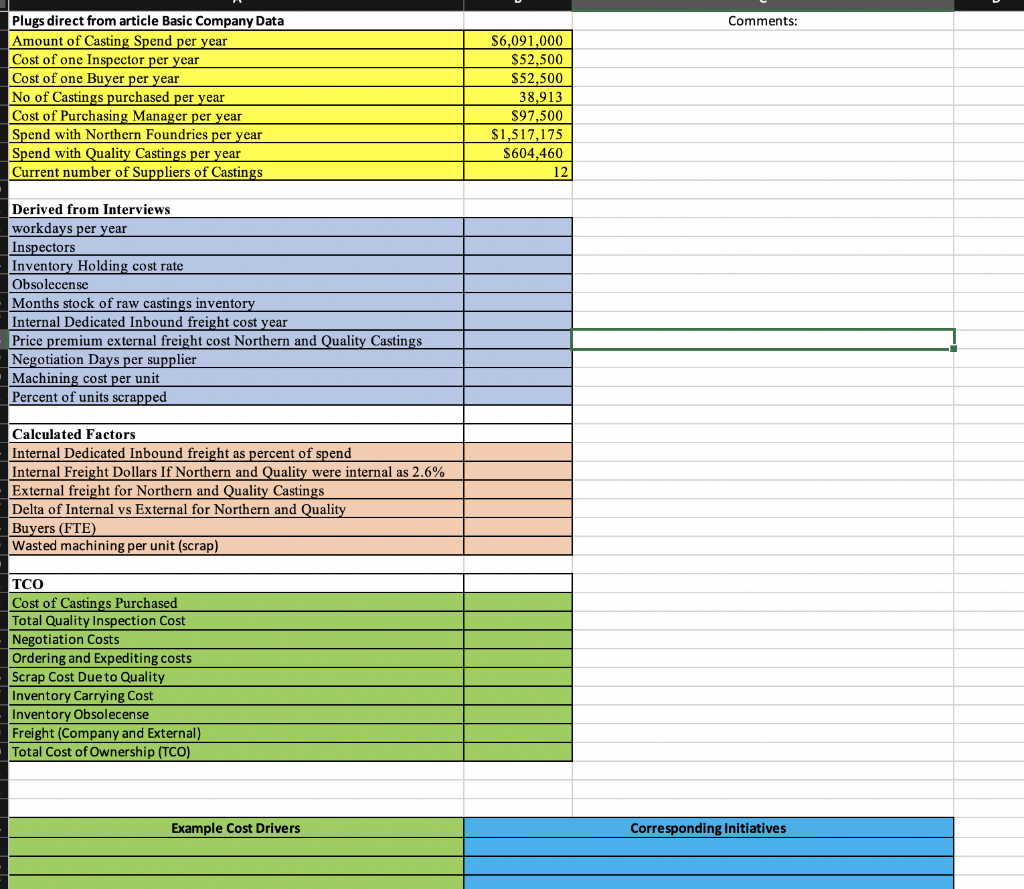

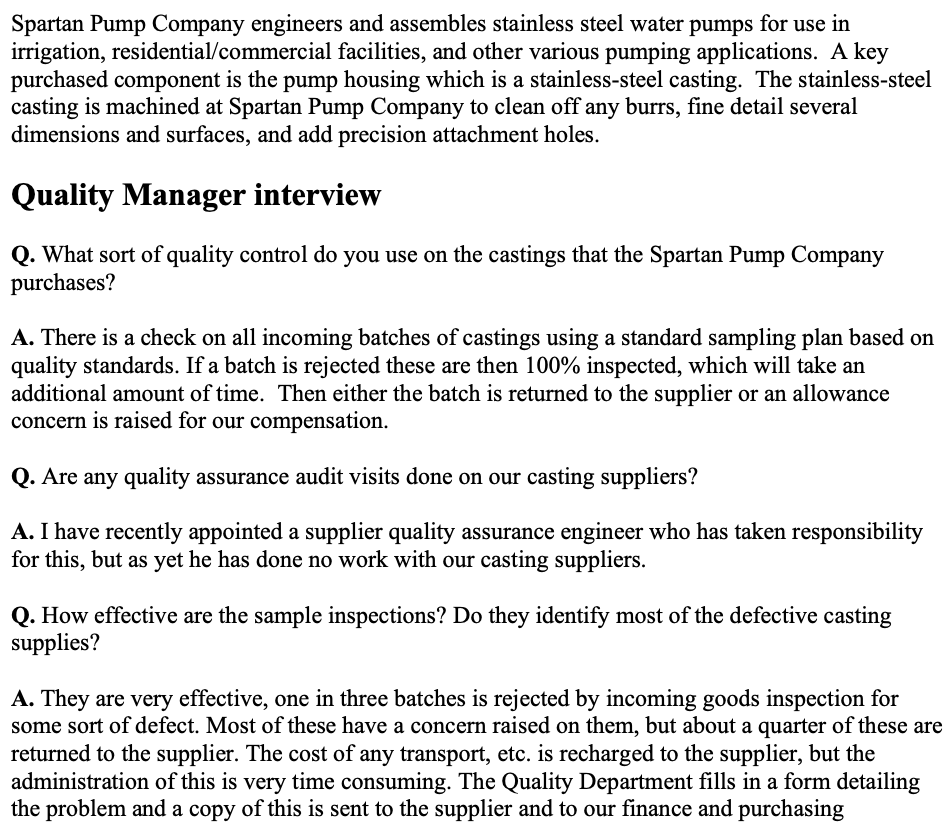

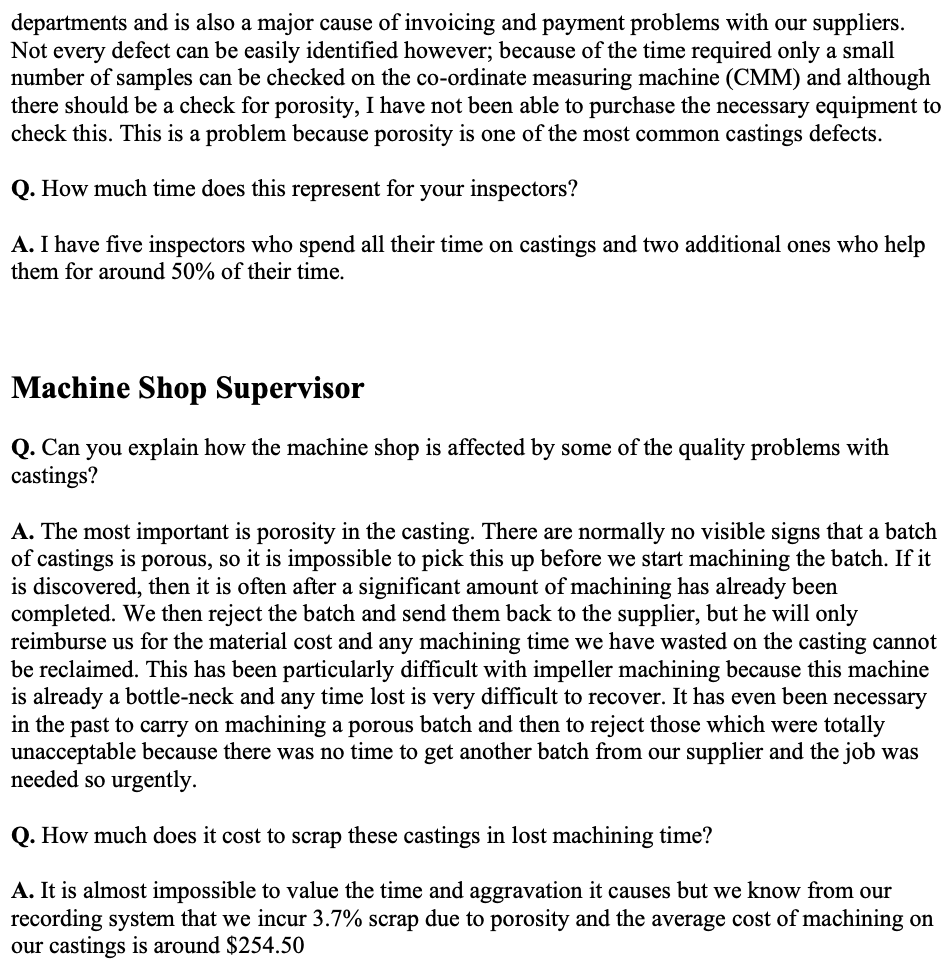

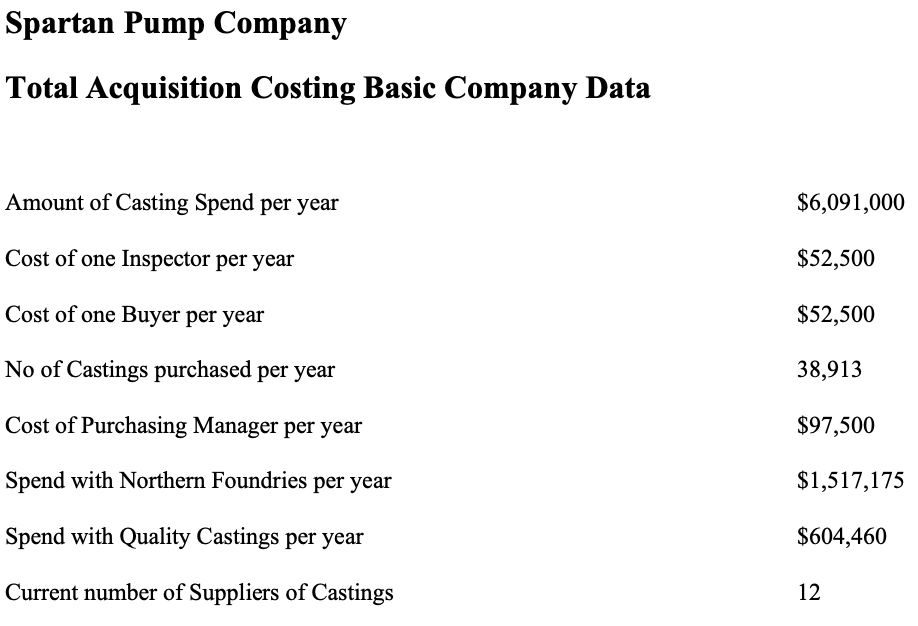

Spartan Pump Company engineers and assembles stainless steel water pumps for use in irrigation, residential/commercial facilities, and other various pumping applications. A key purchased component is the pump housing which is a stainless-steel casting. The stainless-steel casting is machined at Spartan Pump Company to clean off any burrs, fine detail several dimensions and surfaces, and add precision attachment holes. Quality Manager interview Q. What sort of quality control do you use on the castings that the Spartan Pump Company purchases? A. There is a check on all incoming batches of castings using a standard sampling plan based on quality standards. If a batch is rejected these are then 100% inspected, which will take an additional amount of time. Then either the batch is returned to the supplier or an allowance concern is raised for our compensation. Q. Are any quality assurance audit visits done on our casting suppliers? A. I have recently appointed a supplier quality assurance engineer who has taken responsibility for this, but as yet he has done no work with our casting suppliers. Q. How effective are the sample inspections? Do they identify most of the defective casting supplies? A. They are very effective, one in three batches is rejected by incoming goods inspection for some sort of defect. Most of these have a concern raised on them, but about a quarter of these are returned to the supplier. The cost of any transport, etc. is recharged to the supplier, but the administration of this is very time consuming. The Quality Department fills in a form detailing the problem and a copy of this is sent to the supplier and to our finance and purchasing departments and is also a major cause of invoicing and payment problems with our suppliers. Not every defect can be easily identified however; because of the time required only a small number of samples can be checked on the co-ordinate measuring machine (CMM) and although there should be a check for porosity, I have not been able to purchase the necessary equipment to check this. This is a problem because porosity is one of the most common castings defects. Q. How much time does this represent for your inspectors? A. I have five inspectors who spend all their time on castings and two additional ones who help them for around 50% of their time. Machine Shop Supervisor Q. Can you explain how the machine shop is affected by some of the quality problems with castings? A. The most important is porosity in the casting. There are normally no visible signs that a batch of castings is porous, so it is impossible to pick this up before we start machining the batch. If it is discovered, then it is often after a significant amount of machining has already been completed. We then reject the batch and send them back to the supplier, but he will only reimburse us for the material cost and any machining time we have wasted on the casting cannot be reclaimed. This has been particularly difficult with impeller machining because this machine is already a bottle-neck and any time lost is very difficult to recover. It has even been necessary in the past to carry on machining a porous batch and then to reject those which were totally unacceptable because there was no time to get another batch from our supplier and the job was needed so urgently. Q. How much does it cost to scrap these castings in lost machining time? A. It is almost impossible to value the time and aggravation it causes but we know from our recording system that we incur 3.7% scrap due to porosity and the average cost of machining on our castings is around $254.50 Purchasing Manager Q. What is the procedure followed for purchasing castings within the Spartan Pump Company? A. Casting suppliers are normally determined when a new product is being designed. The drawings and specifications are sent to a number of suppliers with a request for quotation. When the responses are received, we normally select the supplier with the lowest cost. Q. Does this mean that there is normally only one supplier per part number? A. No, because of the unreliability of most of our suppliers, we try to have at least two suppliers for each part number. This has been possible with most of our agricultural components, but with the volumes of some of our industrial pumps this has not been possible and there is only one supplier. Q. Do you need to maintain high stocks to overcome the reliability of these suppliers? A. In order to ensure that there are always enough castings on hand we try to maintain on average two month's stock of raw castings in the factory. Q. Do you know what the cost of storing this stock is? A. The way we calculate this is to allow 25% of the value of stock as the cost of holding it (per year). Q. Does this mean that a lot of redundant stock is held due to parts becoming redundant? A. Some of our casting stock does become obsolete. In the last year we had to scrap $64,500 of castings that were no longer of any value. There is still some stock that is not of much value that was kept as it still has some value for service parts, although it is not part of our normal production. Q. What transport cost is there to have your castings delivered? A. Nearly all our castings are collected by one of the company's own dedicated vehicles. The cost allocation from the company's transport budget is $103,312. Two of our suppliers, Northern Castings and Quality Castings Limited, are on delivered terms however; on those we pay transport costs additional to the price of the castings. The estimated carriage costs are roughly 7% of product price. Q. What do you do about re-negotiating prices with suppliers? A. Normally, all supplier price increase requests must be justified with data and we will try to negotiate down the size of the increase. I have an overall objective for the cost of direct purchases, and I have to make sure that the total change in purchased cost enables us to achieve this. This means that with each supplier two to three days needs to be spent re-negotiating contracts and preparing for these meetings. Q. Is there much expediting of casting orders? A. Yes, as I explained earlier, our casting suppliers are some of the most unreliable and the buyers in the department need to spend a large amount of their time expediting their orders. Q. How much time is spent in this activity? A. I have two buyers who are primarily concerned with castings. They spend 85% of their time on castings. Their time is spent placing the original orders and then chasing these orders. This is particularly important in castings as there is a greater amount of variety than other components and so it is more difficult to have the right parts in stock. They are not normally as involved with the negotiation of contracts which I or my deputy tend to handle. Spartan Pump Company Spartan Pump Company Total Acquisition Costing Basic Company Data Amount of Casting Spend per year $6,091,000 Cost of one Inspector per year $52,500 Cost of one Buyer per year $52,500 No of Castings purchased per year 38,913 Cost of Purchasing Manager per year $97,500 Spend with Northern Foundries per year $1,517,175 Spend with Quality Castings per year $604,460 Current number of Suppliers of Castings 12 Comments: Comments: Plugs direct from article Basic Company Data Amount of Casting Spend per year Cost of one Inspector per year Cost of one Buyer per year No of Castings purchased per year Cost of Purchasing Manager per year Spend with Northern Foundries per year Spend with Quality Castings per year Current number of Suppliers of Castings $6,091,000 $52,500 $52,500 38,913 $97,500 $1,517,175 $604,460 12 Derived from Interviews workdays per year Inspectors Inventory Holding cost rate Obsolecense Months stock of raw castings inventory Internal Dedicated Inbound freight cost year Price premium external freight cost Northern and Quality Castings Negotiation Days per supplier Machining cost per unit Percent of units scrapped Calculated Factors Internal Dedicated Inbound freight as percent of spend Internal Freight Dollars If Northern and Quality were internal as 2.6% External freight for Northern and Quality Castings Delta of Internal vs External for Northern and Quality Buyers (FTE) Wasted machining per unit (scrap) TCO Cost of Castings Purchased Total Quality Inspection Cost Negotiation Costs Ordering and Expediting costs Scrap Cost Due to Quality Inventory Carrying Cost Inventory Obsolecense Freight (Company and External) Total Cost of Ownership (TCO) Example Cost Drivers Corresponding Initiatives