Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Assume that a plant produces 4,000 units of product A and 1,000 units of product B, and that each unit (whether A or B) requires

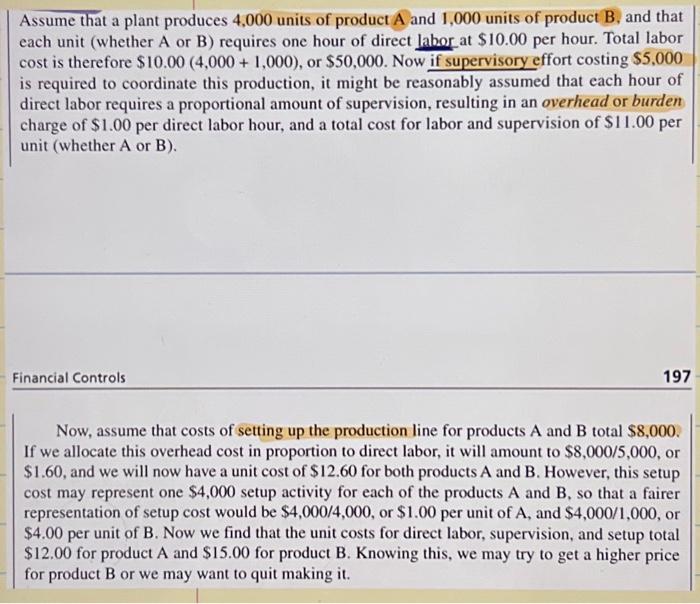

Assume that a plant produces 4,000 units of product A and 1,000 units of product B, and that each unit (whether A or B) requires one hour of direct labor at $10.00 per hour. Total labor cost is therefore $10.00 (4,000 + 1,000), or $50,000. Now if supervisory effort costing $5,000 is required to coordinate this production, it might be reasonably assumed that each hour of direct labor requires a proportional amount of supervision, resulting in an overhead or burden charge of $1.00 per direct labor hour, and a total cost for labor and supervision of $11.00 per unit (whether A or B). Financial Controls 197 Now, assume that costs of setting up the production line for products A and B total $8,000. If we allocate this overhead cost in proportion to direct labor, it will amount to $8,000/5,000, or $1.60, and we will now have a unit cost of $12.60 for both products A and B. However, this setup cost may represent one $4,000 setup activity for each of the products A and B, so that a fairer representation of setup cost would be $4,000/4,000, or $1.00 per unit of A, and $4,000/1,000, or $4.00 per unit of B. Now we find that the unit costs for direct labor, supervision, and setup total $12.00 for product A and $15.00 for product B. Knowing this, we may try to get a higher price for product B or we may want to quit making it.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started