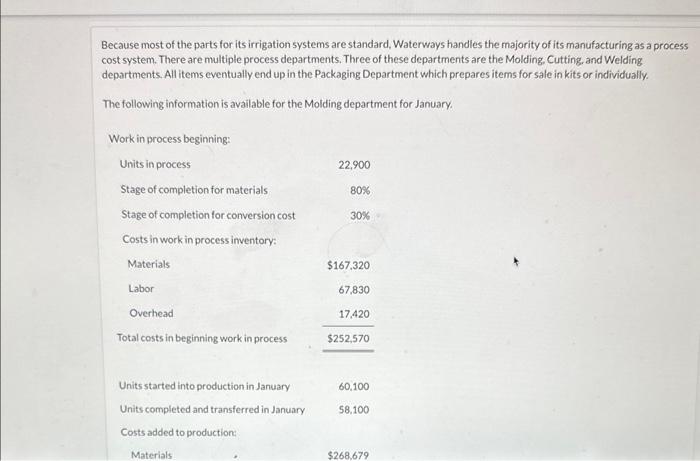

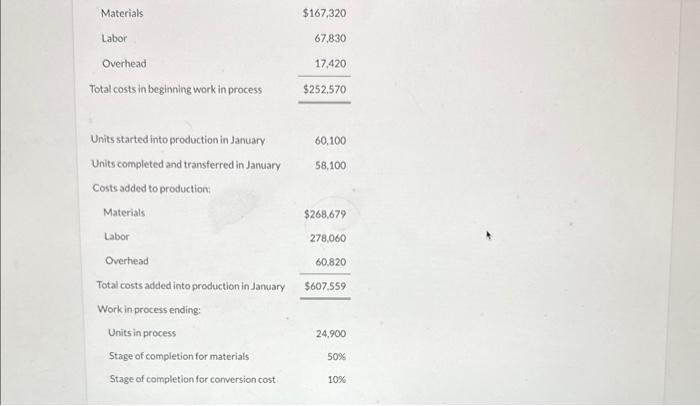

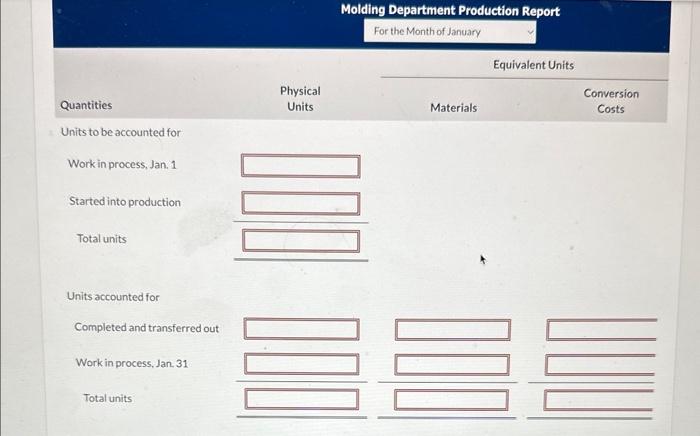

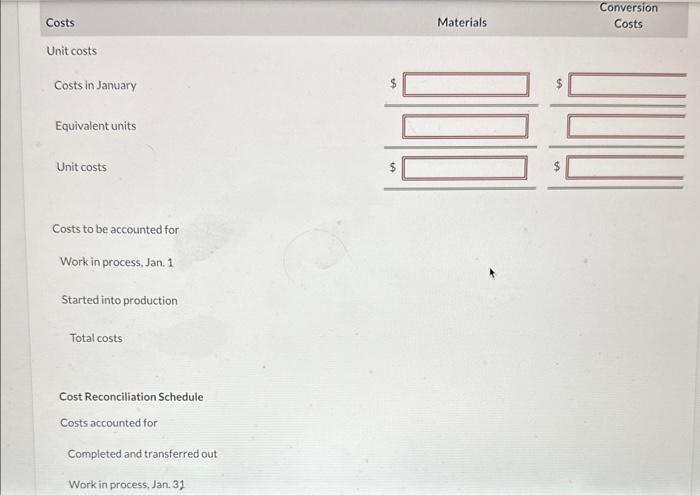

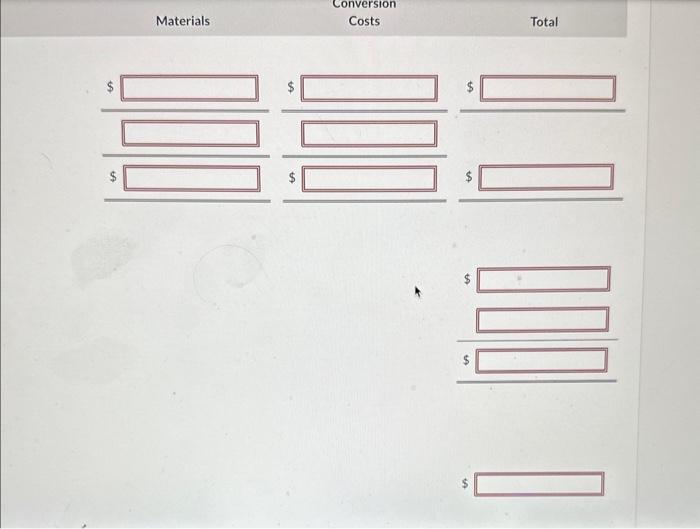

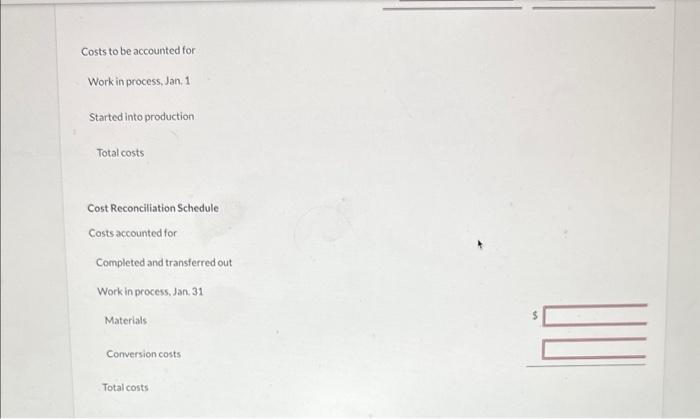

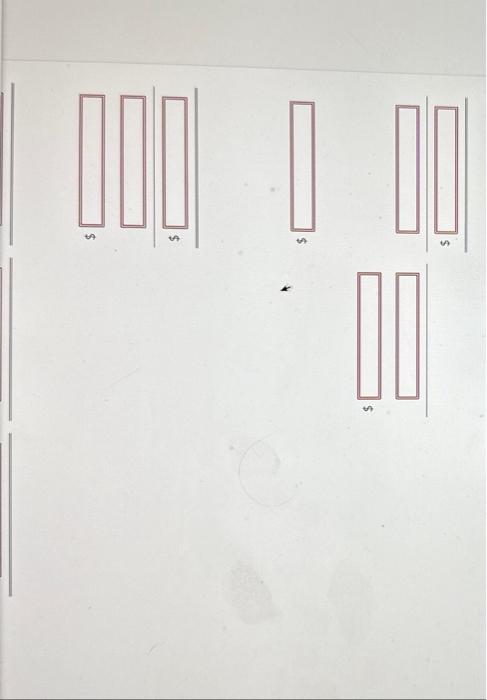

Because most of the parts for its irrigation systems are standard, Waterways handles the majority of its manufacturing as a process cost system. There are multiple process departments. Three of these departments are the Molding, Cutting, and Welding. departments. All items eventually end up in the Packaging Department which prepares items for sale in kits or individually. The following information is available for the Molding department for January. \begin{tabular}{lr} Materials & $167,320 \\ Labor & 67,830 \\ Overhead & 17,420 \\ \hline Total costsin beginning work in process & $252,570 \\ \hline \end{tabular} Units started into production in January 60,100 Units completed and transferred in January 58,100 Costs added to production: Materials Labor 278,060 OverheadTotalcostsaddedintoproductioninJanuary60.820$607.559 Workin process ending: Units in process 24,900 Stage of completion for materials 50% Stage of completion for conversion cost 10% Molding Department Production Report For the Month of January QuantitiesPhysicalUnitsConversionMaterialsCosts Units to be accounted for Work in process, Jan. 1 Started into production Total units Units accounted for Completed and transferred out Work in process, Jan. 31 Total units Conversion Costs Materials Costs Unit costs Costs in January Equivalent units Unit costs Costs to be accounted for Work in process, Jan. 1 Started into production Total costs Cost Reconciliation Schedule Costs accounted for Completed and transferred out Work in process, Jan. 31 MaterialsCostsTotal $ Costs to be accounted for Work in process, Jan. 1 Started into production Total costs Cost Reconciliation Schedule Costs accounted for Completed and transferred out Work in process, Jan. 31 Materials Conversion costs Total costs Because most of the parts for its irrigation systems are standard, Waterways handles the majority of its manufacturing as a process cost system. There are multiple process departments. Three of these departments are the Molding, Cutting, and Welding. departments. All items eventually end up in the Packaging Department which prepares items for sale in kits or individually. The following information is available for the Molding department for January. \begin{tabular}{lr} Materials & $167,320 \\ Labor & 67,830 \\ Overhead & 17,420 \\ \hline Total costsin beginning work in process & $252,570 \\ \hline \end{tabular} Units started into production in January 60,100 Units completed and transferred in January 58,100 Costs added to production: Materials Labor 278,060 OverheadTotalcostsaddedintoproductioninJanuary60.820$607.559 Workin process ending: Units in process 24,900 Stage of completion for materials 50% Stage of completion for conversion cost 10% Molding Department Production Report For the Month of January QuantitiesPhysicalUnitsConversionMaterialsCosts Units to be accounted for Work in process, Jan. 1 Started into production Total units Units accounted for Completed and transferred out Work in process, Jan. 31 Total units Conversion Costs Materials Costs Unit costs Costs in January Equivalent units Unit costs Costs to be accounted for Work in process, Jan. 1 Started into production Total costs Cost Reconciliation Schedule Costs accounted for Completed and transferred out Work in process, Jan. 31 MaterialsCostsTotal $ Costs to be accounted for Work in process, Jan. 1 Started into production Total costs Cost Reconciliation Schedule Costs accounted for Completed and transferred out Work in process, Jan. 31 Materials Conversion costs Total costs