Answered step by step

Verified Expert Solution

Question

1 Approved Answer

BUSN 6051: Supply Chain Management Orion Foods Inc. By Ronald H. Ballou RO Orion Foods, Inc. Anita Bailey is the newly appointed traffic manager

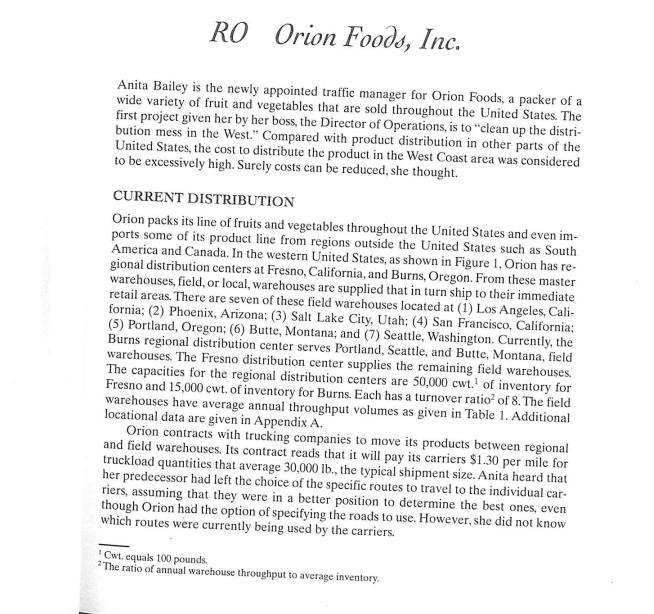

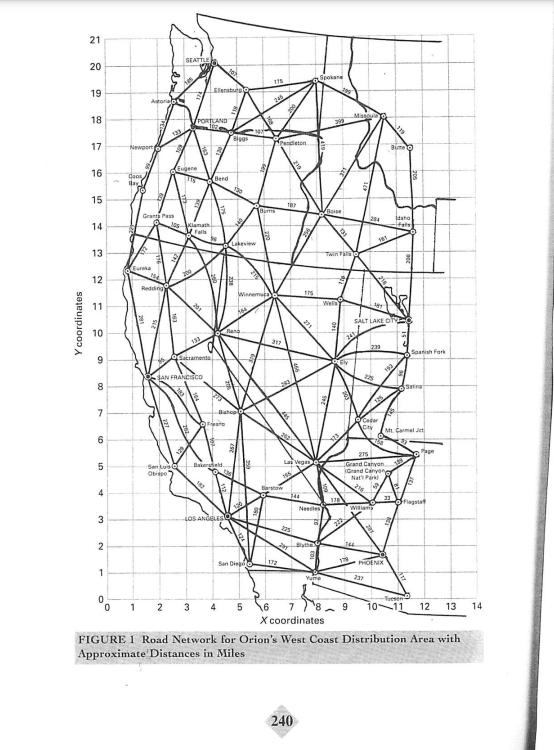

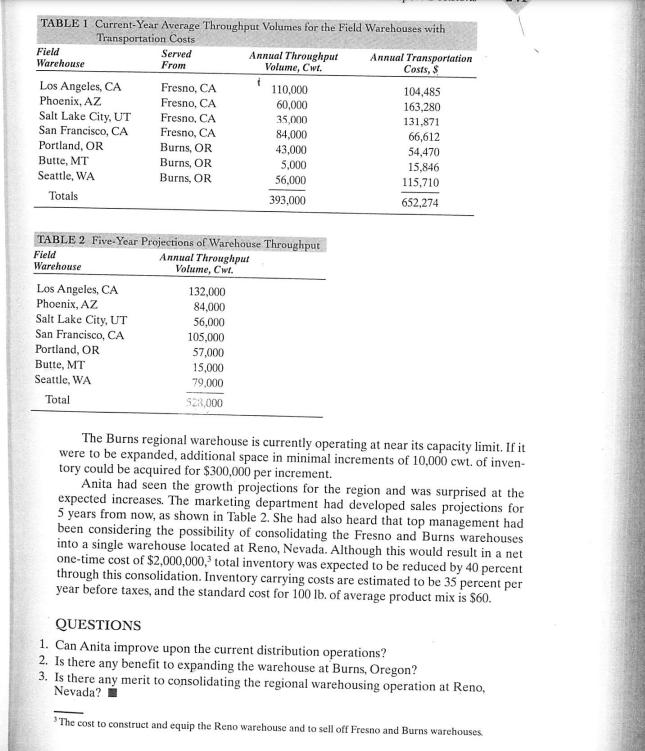

BUSN 6051: Supply Chain Management Orion Foods Inc. By Ronald H. Ballou RO Orion Foods, Inc. Anita Bailey is the newly appointed traffic manager for Orion Foods, a packer of a wide variety of fruit and vegetables that are sold throughout the United States. The first project given her by her boss, the Director of Operations, is to "clean up the distri- bution mess in the West." Compared with product distribution in other parts of the United States, the cost to distribute the product in the West Coast area was considered to be excessively high. Surely costs can be reduced, she thought. CURRENT DISTRIBUTION Orion packs its line of fruits and vegetables throughout the United States and even im- ports some of its product line from regions outside the United States such as South America and Canada. In the western United States, as shown in Figure 1, Orion has re- gional distribution centers at Fresno, California, and Burns, Oregon. From these master warehouses, field, or local, warehouses are supplied that in turn ship to their immediate retail areas. There are seven of these field warehouses located at (1) Los Angeles, Cali- fornia; (2) Phoenix, Arizona; (3) Salt Lake City, Utah; (4) San Francisco, California; (5) Portland, Oregon; (6) Butte, Montana; and (7) Seattle, Washington. Currently, the Burns regional distribution center serves Portland, Seattle, and Butte, Montana, field warehouses. The Fresno distribution center supplies the remaining field warehouses. The capacities for the regional distribution centers are 50,000 cwt. of inventory for Fresno and 15,000 cwt. of inventory for Burns. Each has a turnover ratio of 8. The field warehouses have average annual throughput volumes as given in Table 1. Additional locational data are given in Appendix A. Orion contracts with trucking companies to move its products between regional and field warehouses. Its contract reads that it will pay its carriers $1.30 per mile for truckload quantities that average 30,000 lb., the typical shipment size. Anita heard that her predecessor had left the choice of the specific routes to travel to the individual car- riers, assuming that they were in a better position to determine the best ones, even though Orion had the option of specifying the roads to use. However, she did not know which routes were currently being used by the carriers. Cwt.equals 100 pounds. The ratio of annual warehouse throughput to average inventory. Y coordinates 21 20 19 18 17 16 15 14 13 12 11 10 9 00 8 7 6 5 4 3 2 1 0 Newport Caps Bax. E Agora 1 Grant Pa Redding 21 18- E 124 S Sentus Obispo 2 SEATTLE Eugene 115 31 5 3 Jas Klamath Falls 709 PORTLAND 102 SAN FRANCISCO da 138 Sacramenta 3 BE Eerste 20 3 Berd 15 Bargeld 18/12 Blas 20 3 LOS ANGELES Q 31 Batop Lakeview Bang WAN 130 San Di Be 343 4 5 $ S 115 Bams 220 ar 317 Pendleton 172 THP 299 20 744 121 175 Las Vega 105 201 240 225 by Bath Nede Spok We Yume 3 7 X coordinates 20 Wels 200 Twintas or 2 21 122 OEV 128 31 32 Mag 244 179 SALT LAKE O Tee 204 William 101 Lay 733 237 215 Grand Canyon, Grand Canyon Natak 2 125 125 Ho Bume PHOENIX 119 10 Casar CAV Mt. Carmel Jet S 33 itato Stats 2 13 Satish Fark Sara Pape O B -Flagstaf -Presen 9 10-11 12 13 14 FIGURE 1 Road Network for Orion's West Coast Distribution Area with Approximate Distances in Miles TABLE I Current-Year Average Throughput Volumes for the Field Warehouses with Transportation Costs Field Warehouse Los Angeles, CA Phoenix, AZ Salt Lake City, UT San Francisco, CA Portland, OR Butte, MT Seattle, WA Totals Los Angeles, CA Phoenix, AZ Salt Lake City, UT San Francisco, CA Served From Portland, OR Butte, MT Seattle, WA Total Fresno, CA Fresno, CA Fresno, CA Fresno, CA Burns, OR Burns, OR Burns, OR Annual Throughput Volume, Cwt. TABLE 2 Five-Year Projections of Warehouse Throughput Field Annual Throughput Volume, Cwt. Warehouse 132,000 84,000 56,000 105,000 57,000 15,000 79,000 $23,000 f 110,000 60,000 35,000 84,000 43,000 5,000 56,000 393,000 Annual Transportation Costs, S 104,485 163,280 131,871 66,612 54,470 15,846 115,710 652,274 The Burns regional warehouse is currently operating at near its capacity limit. If it were to be expanded, additional space in minimal increments of 10,000 cwt. of inven- tory could be acquired for $300,000 per increment. Anita had seen the growth projections for the region and was surprised at the expected increases. The marketing department had developed sales projections for 5 years from now, as shown in Table 2. She had also heard that top management had been considering the possibility of consolidating the Fresno and Burns warehouses into a single warehouse located at Reno, Nevada. Although this would result in a net one-time cost of $2,000,000, total inventory was expected to be reduced by 40 percent through this consolidation. Inventory carrying costs are estimated to be 35 percent per year before taxes, and the standard cost for 100 lb. of average product mix is $60. QUESTIONS 1. Can Anita improve upon the current distribution operations? 2. Is there any benefit to expanding the warehouse at Burns, Oregon? 3. Is there any merit to consolidating the regional warehousing operation at Reno, Nevada? The cost to construct and equip the Reno warehouse and to sell off Fresno and Burns warehouses.

Step by Step Solution

★★★★★

3.44 Rating (151 Votes )

There are 3 Steps involved in it

Step: 1

1 Yes Anita can improve upon the current distribution operations There are several potential ways th...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started