Answered step by step

Verified Expert Solution

Question

1 Approved Answer

(c) Danger Level: It is the stock level below the Minimum Level. This level indicates the danger point to affect the normal production. When materials

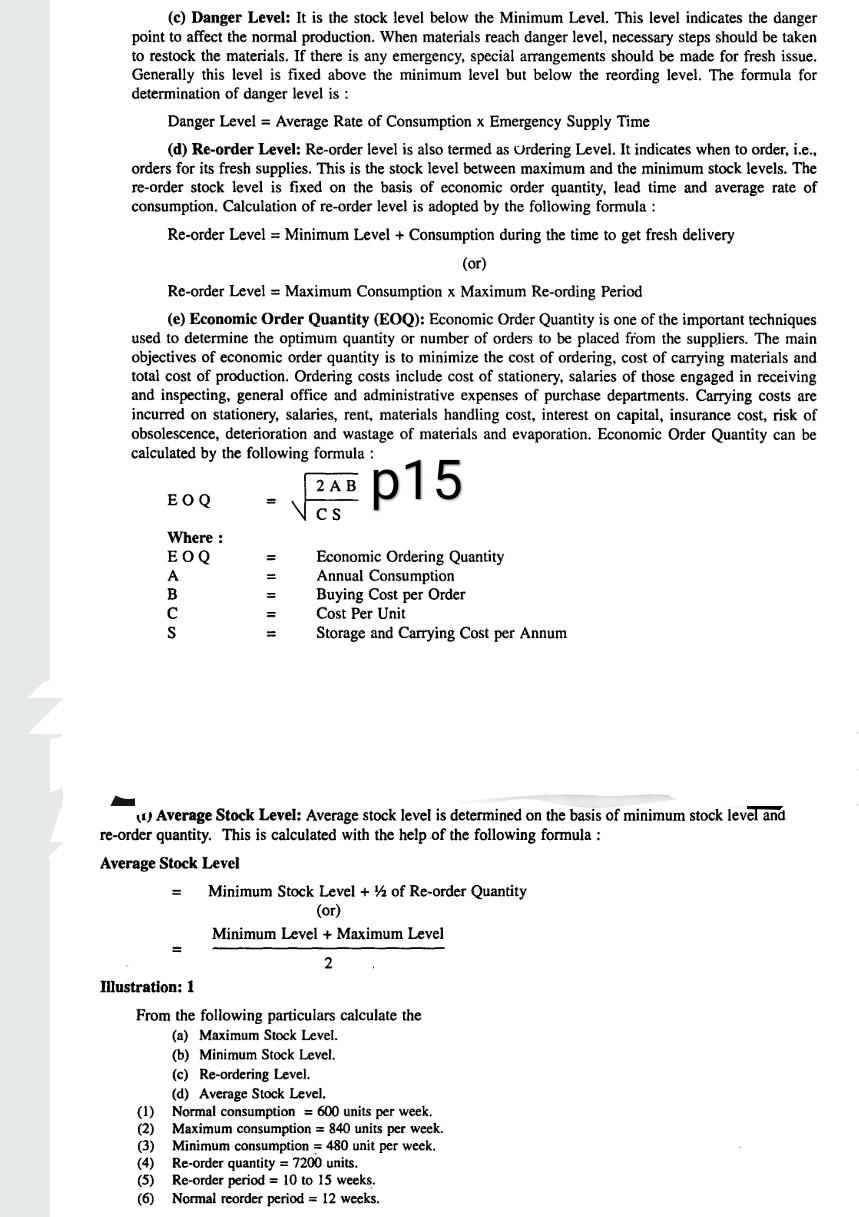

(c) Danger Level: It is the stock level below the Minimum Level. This level indicates the danger point to affect the normal production. When materials reach danger level, necessary steps should be taken to restock the materials. If there is any emergency, special arrangements should be made for fresh issue. Generally this level is fixed above the minimum level but below the reording level. The formula for determination of danger level is : Danger Level = Average Rate of Consumption x Emergency Supply Time (d) Re-order Level: Re-order level is also termed as Ordering Level. It indicates when to order, i.e., orders for its fresh supplies. This is the stock level between maximum and the minimum stock levels. The re-order stock level is fixed on the basis of economic order quantity, lead time and average rate of consumption. Calculation of re-order level is adopted by the following formula: Re-order Level = Minimum Level + Consumption during the time to get fresh delivery (or) Re-order Level = Maximum Consumption x Maximum Re-ording Period (e) Economic Order Quantity (EOQ): Economic Order Quantity is one of the important techniques used to determine the optimum quantity or number of orders to be placed from the suppliers. The main objectives of economic order quantity is to minimize the cost of ordering, cost of carrying materials and total cost of production. Ordering costs include cost of stationery, salaries of those engaged in receiving and inspecting, general office and administrative expenses of purchase departments. Carrying costs are incurred on stationery, salaries, rent, materials handling cost, interest on capital, insurance cost, risk of obsolescence, deterioration and wastage of materials and evaporation. Economic Order Quantity can be calculated by the following formula: 2 AB EOQ CS Where : EOQ Economic Ordering Quantity Annual Consumption Buying Cost per Order Cost Per Unit S Storage and Carrying Cost per Annum p15 B (1) Average Stock Level: Average stock level is determined on the basis of minimum stock level and re-order quantity. This is calculated with the help of the following formula : Average Stock Level Minimum Stock Level + 1 of Re-order Quantity (or) Minimum Level + Maximum Level 2 Illustration: 1 From the following particulars calculate the (a) Maximum Stock Level. (6) Minimum Stock Level. (c) Re-ordering Level. (d) Average Stock Level. (1) Normal consumption = 600 units per week. (2) Maximum consumption = 840 units per week. (3) Minimum consumption = 480 unit per week. (4) Re-order quantity = 7200 units. (5) Re-order period = 10 to 15 weeks. (6) Normal reorder period = 12 weeks

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started